When you have the perfect design to create on your 3D printer, you don’t want there to be any issues, including brittle PLA filament. When this happens, your design can snap easily, rendering all your hard work useless. While you might want to look at your design, just in case, there are many reasons why your PLA filament has become brittle.

We’ll look at the reasons this happens, how to prevent them, and if need be, how to fix them. 3D printing should be a fun hobby and we want to take any frustrations out of the equation, including have PLA filament that ruins everything.

PLA filament, also known as Polylactic Acid, is a common material when creating with a 3D printer. It is a popular choice because it does not need a heated bed and can be used with a lower temperature. While there are a lot of great benefits of using PLA filament, it does have a weakness to be aware of, in that it can become too brittle to be effective.

3D printing is now more of a mainstream activity Trusted Source The 3-D Printing Revolution It’s happening, and it will transform your operations and strategy. hbr.org than ever before and while this is great, many people are jumping into the hobby without understanding all the basics. This can lead to disappointment if your hard work isn’t as perfect as you want it to be.

If you have a lot of issues with your PLA filament, there are other options to try. While PLA filament is still really good, it does have its issues and it may be worth seeing what else is available.

You can try ABS filament, which stands for Acrylonitrile Butadiene Styrene and is the second most popular filament, after PLA. ABS filament is very easy to use and is incredibly durable. It also has a nice flexibility to it. If you are interested in using 3D printing for cosplay, both PLA and ABS filaments are top choices.

Another option is nylon filament. While its uses are narrower in scope, as it is best for mechanical parts, it is very wear-resistant. Nylon filament is quite cost-effective and offers a great deal of flexibility.

Finally, you can also try HDPE filament. This stands for high-density polyethylene and has the added bonus of being a sustainable material. It is durable and corrosion-resistant. As a bonus, it is great for uses outside as it can resist mold and mildew.

If you aren’t sure if your filament is still ok to use, even if it has been kept in a sunny space, is to look at its color. If the filament has a weaker appearance in its color, this means it has been in the sun for too long.

While the aesthetic appeal of the filament is a concern, this is of course, second only to the integrity of the filament. UV rays cause PLA to become brittle and too weak to be properly used.

Even though PLA filament isn’t as absorbent as other types of filaments, there is still a risk of it absorbing moisture. This can be deceptive because you would think that if you store your PLA filament on a shelf or somewhere that water can’t access it, then it will be ok. However, the air can contain a lot of moisture and if you have your 3D printing area in a basement or a room with high humidity, this can greatly affect the filament.

Once the PLA filament absorbs extra moisture, it then becomes weaker. This might not be evident until you use the filament and then after the object cools, it can become brittle and break apart.

When moisture is inside a material and that material is then exposed to heat, as is the case with 3D printing, the water turns to steam. Even if the filament doesn’t break after it cools, you may still see bubbles or even a popping effect which can impact the integrity of the printed piece.

While it can be quite the disappointment to realize your PLA filament is brittle, there are a few ways to remedy the situation. One of the biggest issues to come out of the expansion of 3D printing Trusted Source The State Of 3D Printing, 2019 Proof of concepts and prototyping dominate 3D printing applications in 2019. www.forbes.com is quality control. If you have a new business that revolves around 3D printing, it is especially important to fix your filament and provide the best quality you possible can.

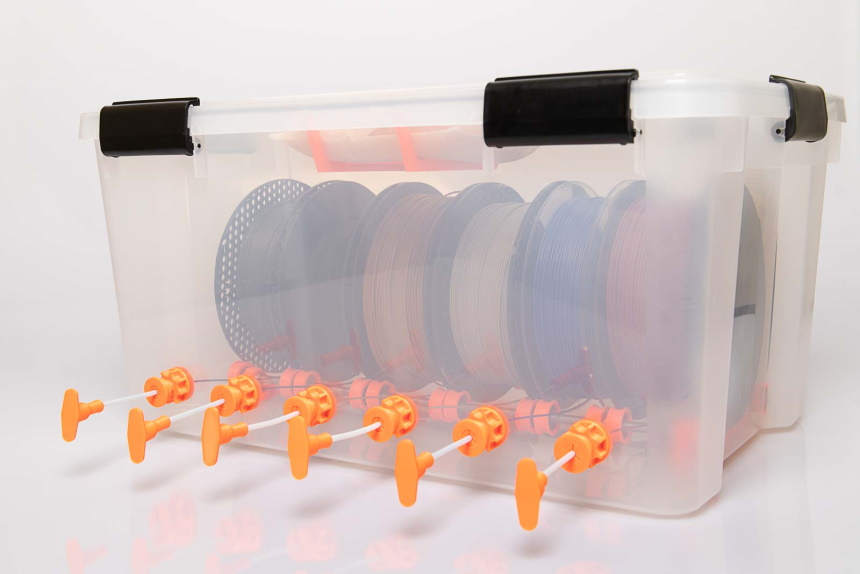

However, if you realize that you’ve merely left your filament out for a few days or it still seems like there is some life left in it, then a filament dryer is a good starting place. You can find many filament dryers on the marker, including the Sovol Filament Dryer SH01. This device will store your filament and act as a dehydrator to keep it at the right texture.

Even if you don’t have PLA filament that has been exposed to moisture, you might want to invest in a dryer as a preventative measure. You can keep a few spools of filament in one and it is crafted to close securely. You can then set the optima temperature and the filament dryer will do all the work for you. This is a great idea especially if you work in a high-moisture area.

Take your whole filament roll and place it in the oven. Now, you want to remove any plastic inserts the roll is on and be sure to put it on a tray, just in case there are some major messes.

The key, however, is that you can’t turn the oven on too hot. Aim for a maximum temperature of 125 degrees Fahrenheit. If your oven does not go that low, you can try a toaster oven but ensure the temperature is nice and low.

Leave the filament in the oven for two hours and if you’re unsure, you can check periodically during this time. After the two hours, take the filament out and test it to see if appears to be less brittle.

To test its brittleness, bend the end of the filament roll. It should be supple and bendy. If it breaks off, it means the filament is still brittle. You can then try again for another two hours but if this still doesn’t change the texture of the filament, then it is unfortunately garbage.

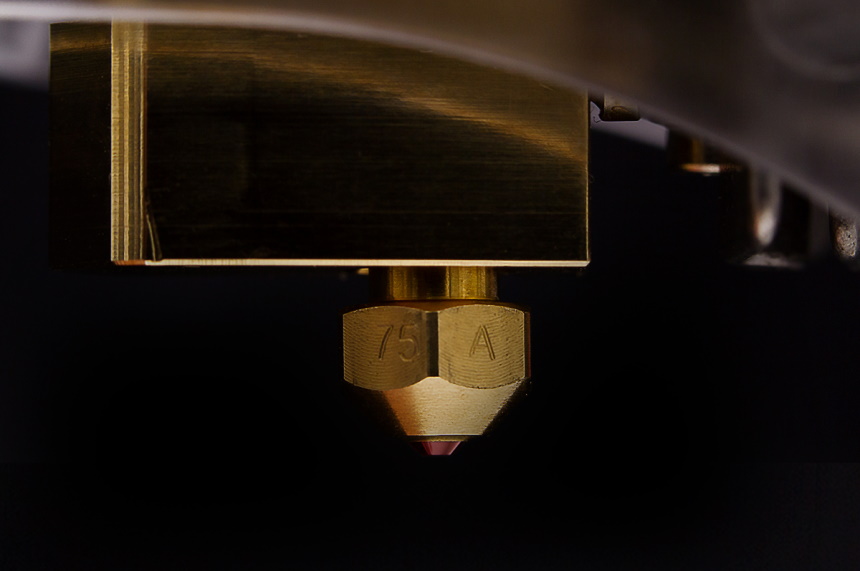

You don’t have to drastically increase the heat temperature of the nozzle but a bit of extra heat may help with any moisture in the filament. Then, while it is in the printer, extra moisture is heated up and hopefully released as you print your object. The filament is able to be a but softer and more pliable and the hope is that as it cools, it is stronger than when it was just a coil of material.

As we mentioned, this process might not work. If your PLA filament is too brittle and has too much moisture exposure, then increasing the heat simply won’t improve it. However, it is a step worth trying. Just don’t spend too much time printing an intricate model as you may be frustrated at the lack of results.

Now that we know the reasons for what makes PLA filament brittle, it’s time to be proactive. These are a few simple steps you can take to keep your filament as strong as possible.

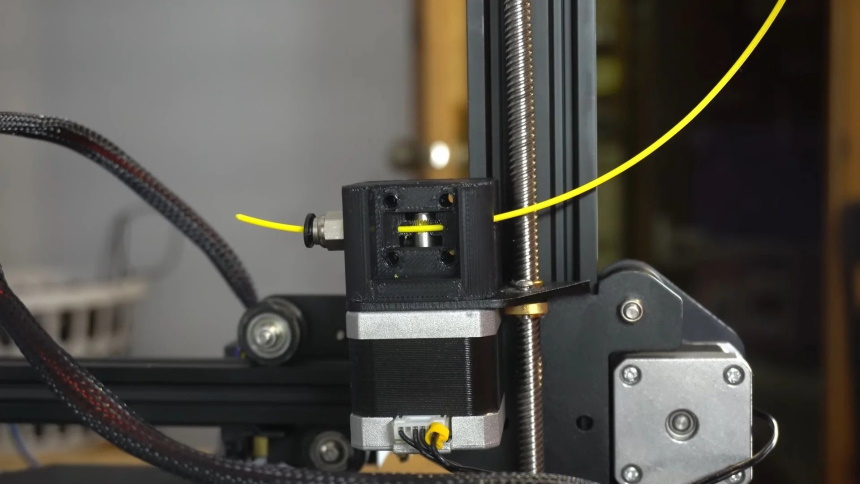

There are a lot of steps when it comes to 3D printing and you may be tempted to omit a few to save you some time and energy. One of these may include not removing the filament from your printer after you are done with it. However, even if you plan on printing again the next day, your filament should always be removed and stored properly.

We’ll talk in a moment about how important it is to have the proper storage for your filament. This can be a box specially made for filament or it can be any storage box that has enough space. You can take a look online for inspiration. The key is to find storage that works for your setup so that you will consistently take your filament out of your printer to keep it nice and strong.

If you can, make sure the container is not clear so as to prevent any UV rays from entering and weakening the filament. If you want a clear container for easier identification, the next best thing is to place it in an area that is completely out of direct sunlight. While a day or two in the sun won’t damage the filament, if left in an area that gets even a small bit of sun, your filament will quickly become too brittle to use.

If you regularly engage in 3D printing, either as a hobby or a business, we know that all the components can quickly add up. You may be tempted to cut corners and purchase PLA filament that is more affordable but of slightly less quality.

This is a mistake.

Always do your research and find the best quality filament that you can afford.

Those with a large workshop for their 3D printing might be best off purchasing a dehumidifier. This is especially important if you work in a basement, which will naturally be quite humid, or even if you live in an area that has a humid climate.

You can find a dehumidifier that works for the space you are in, and they aren’t too expensive. For example, the SEAVON Dehumidifier for Home covers an area of 280 square feet and is small enough to sit on the floor or on a workspace and it won’t get in the way.

There are many reasons why you may find yourself with PLA filament that becomes brittle. It could be that there is too much moisture in the mixture, that the nozzle temperature is off, or even that it wasn’t properly stored. We hope that we have provided some decent preventative measures to ensure your PLA filament stays as sturdy as it needs to be. Brittle PLA filament is an unfortunate side effect of 3D printing but with a bit of knowledge, you can ensure your hobby remains one full of fun and pride.