PLA is a popular plastic material that people in the 3D printing world prefer over the other alternatives available. This material has been helpful in a diverse range of sectors since the 1930s. This thermoplastic is made from renewable sources such as corn starch and sugar cane, among many others. Not all 3D printed items are perfect. Some end products are faulty, and this will necessitate that you dissolve PLA to salvage the raw material and reuse it to save on production costs.

Numerous factors come into play when you want to dissolve PLA. The chemical nature of the plastic and its size are among the principal elements that affect dissolution. In this article, we discuss the top ways to dissolve PLA with and without chemistry. According to reviews, the Dremel Digilab 3D20 3D Printer is one of the top-tier models compatible with PLA. It is an ideal pick for hobbyists, thanks to the superior safety features in place.

Dissolving PLA is not a hard nut to crack if you understand the chemical composition of this thermoplastic. Familiarizing Trusted Source Pros and Cons of the Corn-Based Plastic PLA Although corn-based PLA is a carbon neutral alternative, it has other problems that may limit its use as a replacement for traditional plastics. www.treehugger.com yourself with the material before using it will help you achieve the desired results with ease. PLA, also known as polylactide, comprises lactic monomers from organic sources. It is popular in 3D printing due to its chemical composition that makes plastic versatile and renewable. This chemical dissolves in multiple solutions, including but not limited to acetone, caustic soda, ethyl acetate, and tetrahydrofuran.

When PLA was discovered in the 1920s by Wallace Carothers, the production cost was high, which delayed the use of this material in mass productions. In 1989, a cheaper way to produce PLA Trusted Source The Environmental Impact of Corn-Based Plastics - Scientific American Polylactic acid (PLA), a plastic substitute made from fermented plant starch (usually corn) is quickly becoming a popular alternative to traditional petroleum-based plastics. As more and more countries and states follow the lead of China, Ireland, South Africa, Uganda and San Francisco in banning plastic grocery bags responsible for so much so-called “white pollution” around the world, PLA is poised to play a big role as a viable, biodegradable replacement. www.scientificamerican.com was discovered by Dr. Gruber and his wife. When you take up three-dimensional printing projects, you must familiarize yourself with the different materials. Please pay attention to PLA as it is a multifunctional choice for a host of projects.

The various ways to dissolve PLA that we discuss herein will also come in handy when you clean the 3D printer and free it of PLA and other contaminants when the need arises.

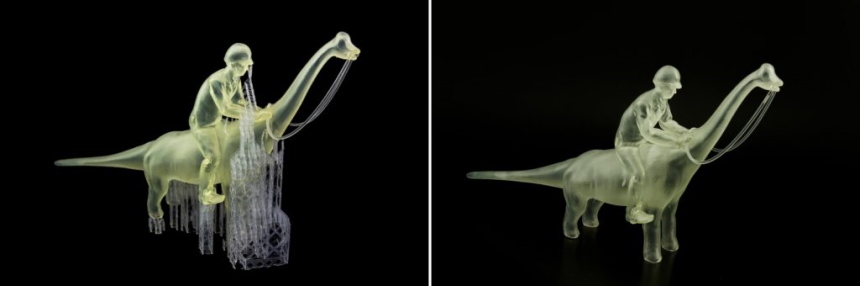

3D printing has its fair share of challenges that you have to deal with when using PLA or any other material in the process. The

chemical nature

Trusted Source

Are bioplastics really better for the environment? Read the fine print | Greenbiz

Confusion among terms like bioplastics, bio-based and biodegradable plastics makes it hard to discern and make the environmentally responsible choice.

www.greenbiz.com

of this thermoplastic is among the top aspects that you have to be familiar with if you want a painless experience. Dissolving the end product is necessary when you cannot smooth out the edges to get a smooth surface. Before you initiate the dissolution process using any available methods, consider smoothing PLA to rectify any imperfections on the model.

Polylactic acid is a biodegradable plastic derived from natural sources. Its chemical formula is (C3H4O2)n, and the melting temperature is between 157 and 170 °C. The typical molding temp for this plastic ranges from 178 to 240 °C. PLA is environmentally friendly as the elements that come together to form this plastic are natural. Manufacturers use a mix of biological raw materials to ensure that the product they release to the market is top-tier.

PLA material is a thermoplastic popular in 3D printing and other applications. Fermentation of carbohydrates such as corn starch in controlled conditions. The fermented starch is then mixed with enzymes or acid and heated to make PLA material. To get the best results when printing using this material, you must adhere to certain conditions to ensure you produce good quality products. You have to know how to dry PLA filaments and store them properly after acquisition for better results.

Dissolving PLA with chemistry means that you require solvents. Numerous alternatives are on offer, but some are harder to come by than others. Below we discuss the top solvents to dissolve PLA with chemistry.

Acetone is a common solvent with multiple applications. It can dissolve PLA, but you have to be careful not to ruin the model you just printed. The main advantage of acetone is that it is easy to get. It is available in many stores across the internet and on land. Acetone makes the surface smooth and sticky. Try using this chemical on a small part of the object first to know how it reacts before using a generous amount on the model you print. Some people choose to dilute acetone to get a less potent version of the chemical.

This chemical is a combination of acetic acid and ethanol. Ethyl acetate can dissolve PLA easily, and it is a popular solvent for this undertaking. Safety is a vital issue that you must bear in mind if you choose to use this chemical. Ethyl acetate is highly flammable.

You have to ensure that your work environment is safe to prevent accidents. Do not use other chemicals alongside this one.

Methyl ethyl ketone (MEK) is another effective chemical that you can use to dissolve PLA. This chemical is hazardous and should only be used in controlled environments. It is not the ideal choice for home use due to the adverse effects it has on the human body. Exposure to MEK can cause headaches, dizziness, and in extreme cases, you may pass out. Repeated eminent exposure can damage the nervous system and damage the brain. Take all the necessary precautions when using this chemical to dissolve PLA.

Tetrahydrofuran, also known as oxycodone, is a strong chemical primarily utilized for industrial needs. It completely dissolves PLA and other materials necessary for efficient 3D printing. This solvent is suitable for many applications, but the risks of using it are also high. The low flash point element makes THF highly flammable. Most producers use tetrahydrofuran vapor to make the surface smooth after printing with PLA. Wear protective gear to ensure you do not inhale the vapor as it is hazardous.

This chemical is among those that you should avoid when dissolving PLA. Try the other alternatives before you get to THF.

It can replace tetrahydrofuran and perform almost similarly without the harmful side effects. However, this is not to say that caustic soda has no adverse reactions to the human body and the environment. Use 120 grams per one liter of water to get the ideal solution for smoothing PLA. Wear protective clothing when working with sodium hydroxide. Previous users have diverse experiences, with some loving the outcomes and others criticizing this solvent, terming it highly aggressive.

Dissolving PLA with chemistry involves introducing chemicals to the environment, and the users are also exposed to multiple risks. Other ways to smooth PLA have been advanced over the years to reduce solvent use. Here are the top options that you have if you choose to smooth PLA without chemistry.

When choosing the filament to use for your project, consider the versatility of the material. For instance, most people review TPU vs. PLA filaments and opt for one appropriate for the project. Using the same material to build and support allows you to get better results when 3D printing.

Sanding helps but does not entirely remove the lines and carrier material. Primer sprays come in handy, and the different brands in the market will help you get the finish you want without using chemicals. Buy sand-able primer spray and use it to achieve the consistency you want for the surface.

These two methods are standard but not the only alternatives you have. You can purchase tools for welding PLA surfaces, and they will help you remove any unwanted features. The comprehensive web has other solutions that you can consider as well. Read expert reviews to gauge the feasibility of the technique you pick.

You need to be safe when printing 3D models and smoothing or dissolving the material you use. Having a safety plan will make your work more manageable, and you will have minimal contact with harmful substances.

If you have no alternative and you opt to use chemistry to dissolve PLA, specific procedures will require you to have an extra layer of protection. From the solvents we discussed above, you have the freedom to work with less harmful chemicals. Always wear protective gear when using chemicals. Read the label to know the main components and avoid situations that might put your life at risk.

The industrial sector ought to have detailed procedures on how to handle the chemicals. Use environmentally safe practices when disposing of used chemicals and residue from the process.

Most people overlook the safety data sheets that guide users on how to dissolve PLA. Experts recommend that you read the fine print and understand the process before you begin any procedure. Some manufacturers do not include a guide in the package that comes your way. Check the solvent labels for instructions on proper use. You can also develop a safety data sheet for your printing business after exploring the various options that work best for the type of printing you engage in and the equipment you have.

Chemicals have pros and cons that you have to evaluate to determine whether to use any of the options ideals for dissolving PLA or not. Here are some of the advantages of using solvents for PLA.

These are some of the top benefits of using solvents for PLA. The chemicals you will come across have specific cons that you must assess before purchasing any available alternatives. Below we discuss the disadvantages of using chemicals to dissolve PLA.

Knowing where to get the chemicals you need to dissolve PLA is critical for anyone in 3D printing. Luckily, most of the substances that you will require are not controlled chemicals. However, you have to pay attention to the intricate details to determine whether the substance you are getting is potent enough for the task at hand. Important to note is that some chemicals that dissolve PLA are controlled in certain jurisdictions, and you have to know the correct way to acquire and store them.

You have the freedom to purchase from both land-based stores and virtual establishments. Buying from a brick-and-mortar store is advisable as you familiarize yourself with the chemicals and the different brands in the market. Ethyl acetate is readily available in auto supply and drug stores, while Methyl ethyl ketone can be found in paint, wallpaper, and hardware stores. The other chemicals are opening-home improvement stores, pharmacies, and tool and craft shops.

The solvents you will use to dissolve PLA are harmful in one way or the other. You have to protect yourself and the environment against any form of contamination. The chemicals react almost instantaneously to the plastic. The concentration of the solvent will determine if the PLA will dissolve faster or slower. The research will help you understand how the chemical you choose will affect the PLA material and the approximate duration to dissolve a specific quantity.

To reduce the amount of solvent you need to dissolve PLA, use a filament dryer to dry your material and reduce waste. Reviews from experts and previous users indicate that the EIBOS filament dryer is one of the best in the market. The adjustable temperature feature alongside humidity control is the desirable element that draws buyers to this dryer. Printing under the right conditions will help you reduce the solvent you use to clean the printer of any waste. Always check and adhere to the manufacturer’s instructions on using a solvent before you begin the process.

Mixing the different solvents available in stores to dissolve PLA is not recommended. The various alternatives you will encounter have varying chemical compositions, and mixing them together is a hazard. High exposure to the solvents can cause unconsciousness and, in some instances, death. For this reason, you should not mix any of the solvents to increase potency and efficiency.

The chemical reactions from mixing any solvents can cause fire or explosions, leading to loss of lives or damage to property. Please read the instructions label on the chemical you buy and use it per the manufacturer’s guide. Consult with an expert on applying the numerous solvents at your disposal before you experiment on the possible chemical reaction from mixing them together.

3D printing is a science that requires you to understand the various elements that come together to guarantee the success of a project. You do not have to dissolve the printed object if your objective is to smooth out rough edges. Using the solvents we discuss above, and you can quickly destroy the print you have. You can avoid extra work by knowing more about the solvents and how to apply them to smoothen the model’s surface.

If you do not want to use chemicals, there are other ways to dissolve PLA that you can explore. The technique you choose to dissolve this thermoplastic is a matter of preference, but you have to assess your needs to ensure that your preferred method is appropriate and safe. Adhere to all the necessary precautions when using the 3D printer and solvents.