Chuck Hull, the inventor of 3D printing in an interview, highlighted that Trusted Source 'The night I invented 3D printing' | CNN Business In 1983, Hull was working for a small business that made tough coatings for tables using ultraviolet lamps. www.cnn.com was the basic methodology of creating 3D prints in the beginning, and it is yet to change. But the process is more advanced in resin 3D prints as they don’t just look better than other types of prints; they are also made faster.

To cure resin, it is first worked on in the printer, and then it can be exposed to UV light to be solidified and shaped. There are several factors that determine how long it takes to cure resin prints, but the major factor is the intensity of the heat.

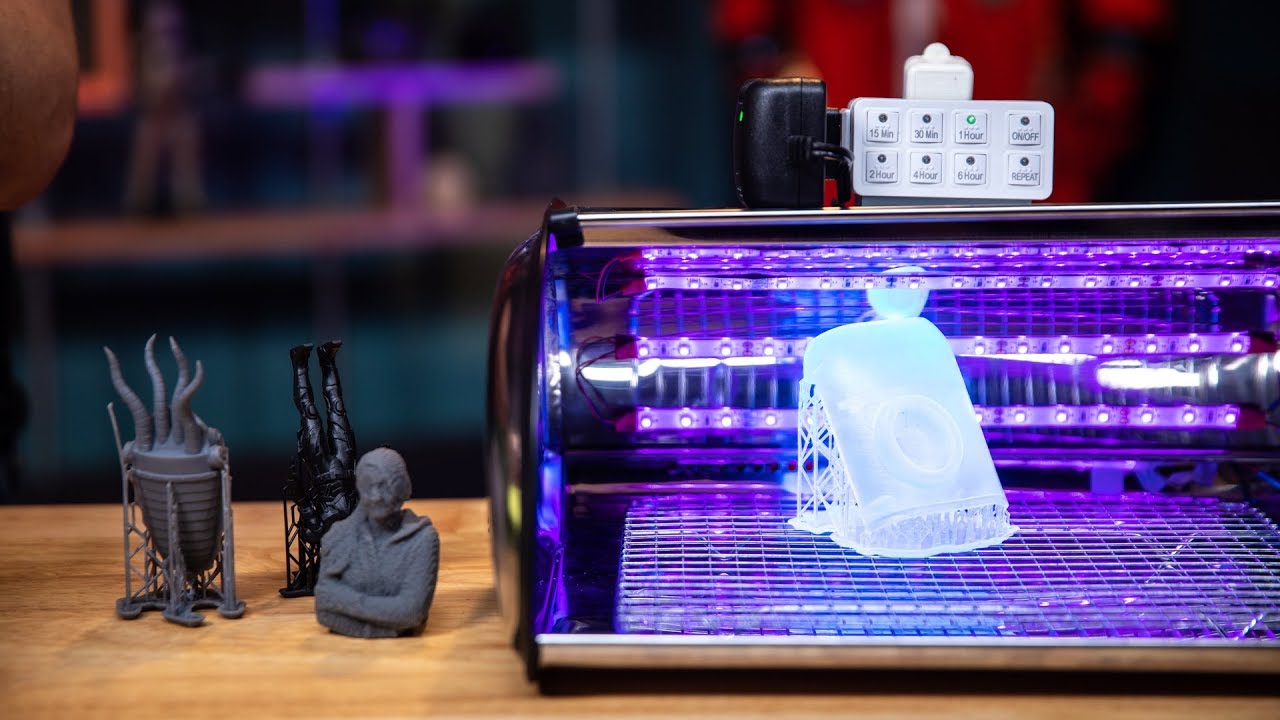

To harden and increase the structural stability of resin prints, a post-printing process is required. The most common way of post-curing is to use a heated UV curing chamber, which reduces the time it takes to get to the finished product.

Curing a resin 3D print means exposing your print to UV light for a certain timeframe. During this time, the chemical components of the photopolymer resin change as the UV lights act on it by hardening it.

When UV keeps on curing a resin print after it has hardened sufficiently for usage, this is known as Over-Curing. One of the ways of over-curing is to leave your resin 3D print in the UV curing station for a prolonged period of time. Another way this occurs is as a result of prolonged UV exposure from sunshine and other ultraviolet sources of light.

However, printing with resin is a very easy process that can be done within a short frame of time. Resin prints have a more consistent finish throughout the curing process, resulting in a strong composition. The curing process also results in products that are durable and appealing to the eye.

But because of the intense heat that perfects the curing process, over-curing happens, causing the print to be brittle easily. It doesn’t stop with the heat and UV light used during the curing process; sunlight also heats it up. The bottom line is that even after over-curing is avoided in the curing stage, it can’t be avoided as long as it will be taken out for sunlight.

The only scenario where resin print stops curing when exposed to sunlight is if you embody it with a UV protective layer.

Curing your print is as important as preventing your print from over-curing. Amongst the very few post-curing lamps that deliver within a few seconds and last long for over 30 years is Phrozen Cure. When prints are over-cured, they become brittle, and their impact resistance deteriorates with time. In such cases, their structural stability is severely affected.

There are a number of factors that determine the length of time needed to cure resin prints. Amongst them are:

Resin print is to be cured for as much time as it will take for it to be strong and stable. A properly cured print will last for a very long time, and this can only be made by the best corexy 3D printers in the market.

However, prints shouldn’t be over-cured as they will become more brittle if they are; they become extremely hard and fragile. You should take note of the difference in the print as you perform the curing process, as over-curing sometimes happens when you fail to pay close attention to the process.

Over-curing a resin print by keeping it in a high-intensity UV curing station over the night is a good example. Another issue that might cause unintended over-curing is direct sunlight.

Another factor determining how long prints will be cured is the size of the print. The amount of surface area and volume significantly impacts the time it takes for the resin to cure completely.

Large prints take more time than small prints as a number of minutes will be spent on making sure that all the layers and points of the print are properly cured.

All prints, especially large ones, while exposing them to UV light, should be rotated to vary their direction so that they can be cured uniformly. This is why revolving plates are included in the curing station.

Resin 3D prints that have opaque materials, such as black and gray, take more time to cure than transparent prints.

Because of their distinct qualities, transparent and clear resin takes less time to cure than colored resin. Users recommend Phrozen SC-801 Clear Resin, a great resin for transparent prints; it gives crystal clear results. UV light can pass through such print much more easily.

One other factor that influences how long it takes to cure resin prints is the means you use. There are two distinct means of curing resins – curing in the sun and under UV lights; these two methods produce heat differently. Intense heat comes from the UV lights, and it reacts closely on all the layers of the print, but the heat from the sun isn’t that effective.

Also, while looking to purchase a UV curing light, you will see those with big lights and those with small ones. The big resin curing lights have a lot of power; they would take a lot shorter time to cure, even less than a minute in some cases.

Choosing to cure your resin in the sun is also an option, but it is not advisable because it is difficult to say how long it will take. The curing period for a resin put in the sun is determined by the degree of UV the sun is emitting.

Resin prints need to be handled with care both during the curing stage and the post-curing stage. They should not be over-cured if you want them to last for long and still maintain their appealing appearance.

Shortly, some tips on how not to over-cure your resin 3D prints will be shared.

As previously said, resin 3D prints can be cured through UV light and sunlight. How long it takes to cure 3D resin print in the sun is different from the time taken under UV light. So, in this next phase of this write-up, we will be talking about how long it takes to cure resin prints in the sun and how long it takes to cure resin prints under UV light.

Curing resin prints in the sun is a time-consuming task. It can take up to a few hours and more if the sun’s temperature is not very hot. You will also have to turn your print to the other side after a while in order to get uniformity.

Natural UV radiation has a limited reach, but the deteriorating effect it has on the resin is readily apparent. UV is emitted by sunlight, and this keeps on curing the resin print as long as it’s in a place where the sun’s rays can reach.

When you put a resin print under the UV light, the initial process that takes place is Trusted Source Photopolymerization | ScienceDirect Photopolymerization is a technique that uses light (visible or ultraviolet; UV) to initiate and propagate a polymerization reaction to form a linear or cross-linked polymer structure. www.sciencedirect.com . It hardens, stabilizes, and strengthens resin prints until they reach their structural and aesthetic qualities. When this occurs, the print is said to be “properly cured.”

Resin prints are cured faster under UV light compared to sunlight. Small and transparent prints can be cured in a minute or less, while average and large prints take a little bit longer but not usually more than 15 minutes. Brittleness will develop if you leave a resin print in your UV curing machine for longer than necessary.

You can cure your resin 3D print by exposing it to UV light. Direct sunshine, UV lamps, and specific UV curing devices are all examples of UV light sources. Heat is also applied by the sources of light to speed up the curing process. If you are curing via sunlight, soaking the 3D print in water can help speed up the process.

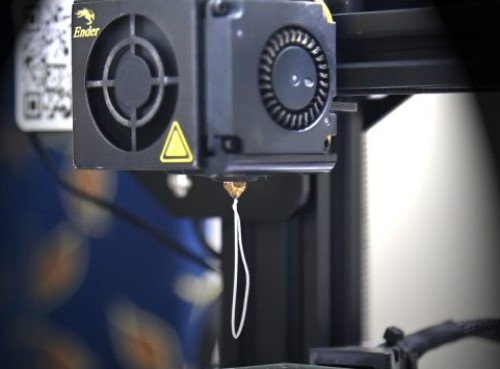

When the resin is finally printed, use a sharp tool to scrape off any unclean part. Then, clean it using isopropyl alcohol – it takes off any uncured resin on the 3D print. You can also polish and paint your 3D prints to make them look better.

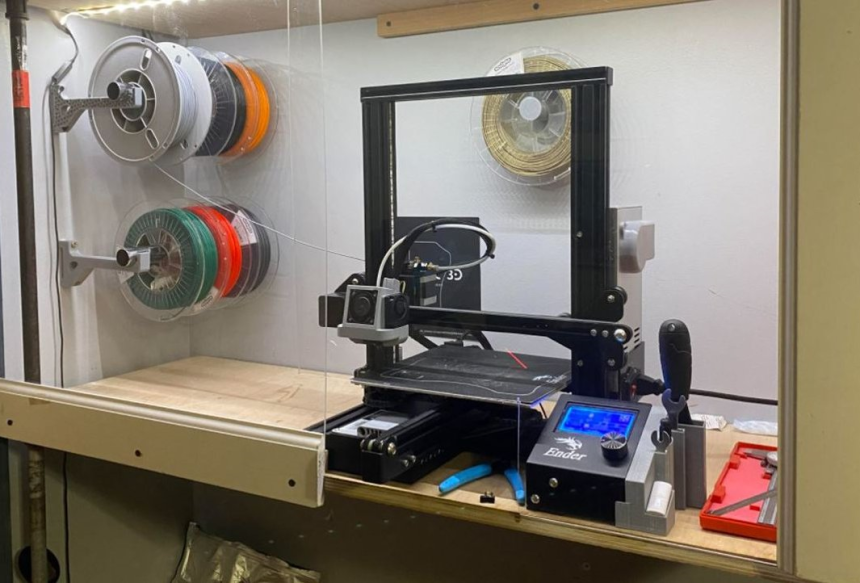

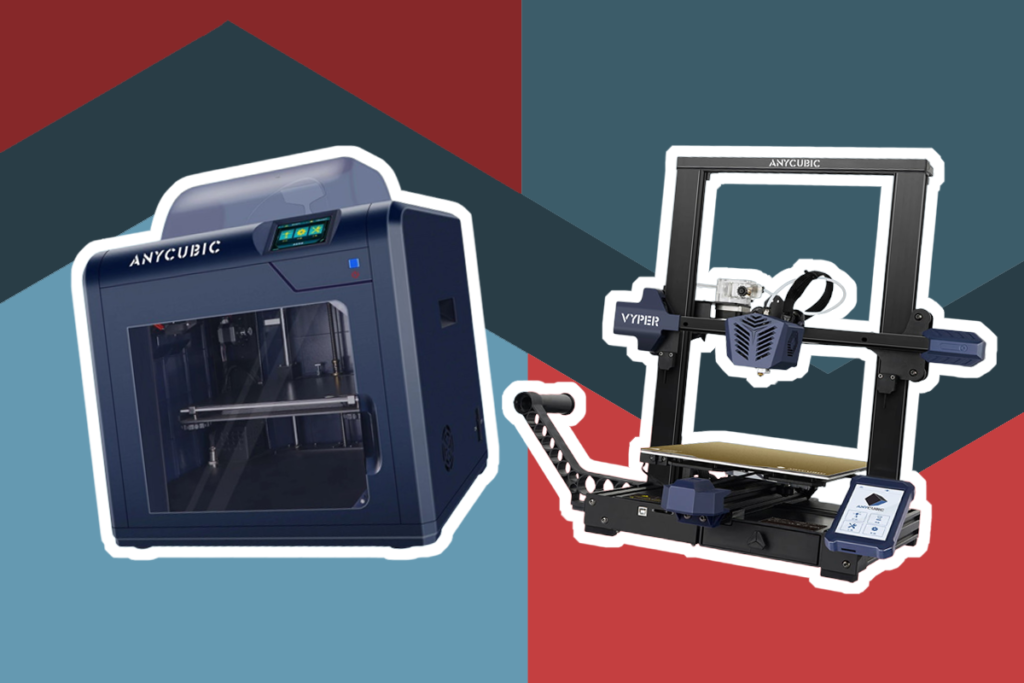

To avoid much work of cleaning and polishing prints, you should get easy-to-use printers that won’t stress you.

The primary cause of a sticky 3D print is under-curing. If your resin 3D print is not properly cured, it will become sticky. To have it in the texture and shape you want, all you have to do is to complete the curing process. Curing the print in layers or slowly curing it with mild UV light is preferable to eliminate stickiness. You can also expose the print to UV rays in direct sunlight.

UV light and sunlight are the major means used in curing resin prints. But UV light is preferable to sunlight because it’s faster.

Resin 3D prints have to be cured properly in order to be strong, durable, and have a beautiful design. UV exposure has the ability to solidify and stabilize your resin print. However, once the resin print has reached its maximum sturdiness and it’s not removed from the light, it will start getting damaged.

The desired quality of the product, the size of the print, the print type and color, and the method used to cure the print are the major factors that influence how long it takes to cure resin prints.