Plastic is invading our planet at a rapid pace. In a single year, thousands of marine life are subjected to risks such as plastic ingestion and entanglement due to overcrowding in our landfills. For that reason, we all must practice better eco-friendly habits and use less plastic whenever possible.

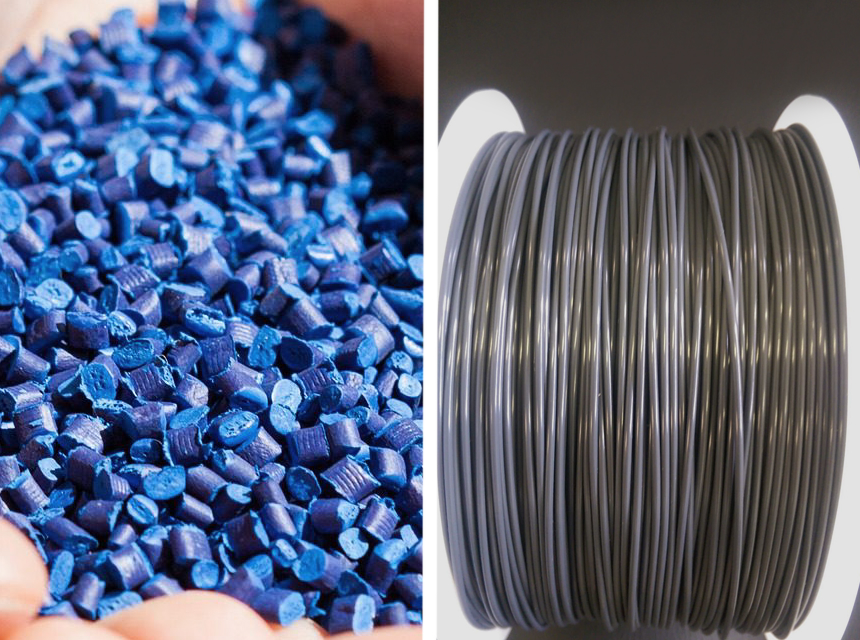

One of the ways people are cutting down on their plastic waste is by recycling 3D printer filament. Owners of 3D printers are now choosing more green 3D printing options that involve reducing, reusing, and recycling all the plastic leftover from their failed printing projects. Digital printing enthusiasts must learn to make better use of their ABS and PLA materials since this form of plastic can take anywhere from ten up to one hundred years to decompose.

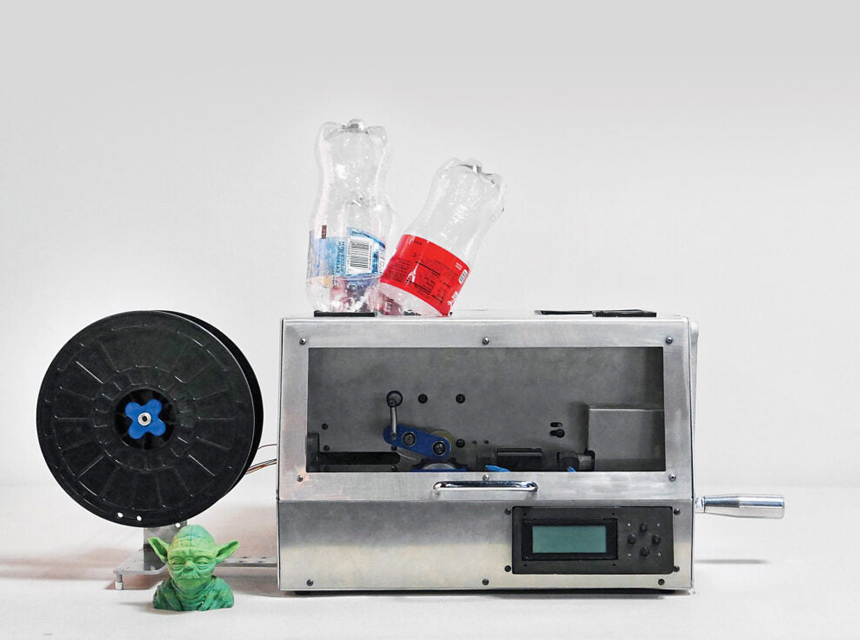

You will need a few extra tools to successfully recycle your own 3D printer plastic waste into brand new spools. First and most importantly, you will need to purchase a 3D printer filament recycler. This product will crush the failed projects into much smaller pieces and then melt those pieces down into liquid form. After that, the liquid is pushed through an opening, and the hot plastic is cooled down then coiled on a reel, ready to be reused.

You can purchase a shredder for your 3D printer filament, or you can make your own DIY shredder. If you purchase one, you should make sure that it is compatible with the type of plastic filament you use. It’s also vital that you understand how tricky it can be to shred plastic if you are new to the task. Grinding plastic will put a heavy strain on the motors found on ordinary appliances if you are going the DIY route. For best results, you can easily purchase an industrial shredder with a powerful motor designed to cut through ABS, PLA, or HIPS plastic.

An extruder is another item you can make on your own or purchase a ready-made product. There are several extruders on the market; therefore, if you are not particularly crafty when it comes to DIY projects, you may want to purchase one that’s ready to use. Still, you will need to ensure that the extruder you buy works with the type of plastic filament you use in your 3D printer. When using an extruder and PLA filament, you need to make sure the polymer is dry before extruding. PLA will require extra cooling and the assistance of a winder for it to coil correctly.

The Protocycler is the ideal 3D printer filament recycler. This product will quickly grind up plastic into smaller pieces, melt it down, extrude it, and coil it onto a spool with no additional equipment to purchase. It is all controlled by a computer to ensure accuracy and consistency. This is the perfect product for any 3D printing enthusiast who has concerns about plastic waste.

Another option for reducing plastic waste is to create a filament factory. There is a Dutch project known as Precious Plastic that helps people create plastic recycling workshops. They will provide interested individuals with appliances such as a compressor, shredder, extruder, or injection molder to create their own filament factory. The project is helping to create recycling communities in other ways as well. They are currently holding clean-ups and spreading valuable information about the ongoing problem with plastic pollution to empower more individuals to use plastic wisely.

Another thing you can do to help reduce the amount of plastic waste out there is to purchase recycled 3D filament. Buying it instead of brand new filament will help reduce your carbon footprint and cut down on the amount of unwanted plastic waste in our landfills. You can find filament made from a broad range of materials, including beer, coffee, and hemp Trusted Source Yes, you can totally use beer, coffee and hemp for 3D printing If you thought 3D printing was already cool, a startup in North Dakota is turning recycled beer, coffee and hemp into filament for 3D printers. money.cnn.com .

As more people are starting to use 3D printers, the need to recycle plastic waste is growing as well. ABS and PLA are two common 3D printing filaments that are not easy to recycle. That is why there are now 3D printer filament recycling services available. Companies such as RePlAy3D manufacture and distribute 3D printer filament, but they also encourage their customers to recycle their waste products using their program known as Closed=Loop Recycling. With this program, the company collects scraps of filament from their customers and recycles them into new and usable filament.

Recycling 3D printer filament is essential because it can help reduce the amount of plastic waste throughout the world. It can also help those living in developing nations deal with poverty issues. But there are also other reasons why it’s important to recycle your unwanted filament.

There are around 15 million waste pickers all over the world who collect, sort, and process recycled materials. These individuals tend to live in extreme poverty. The Ethical Filament Foundation was made to address this issue and create a fair trade process for the 3D printer filament industry. Through this program, when waste pickers gather plastic filament, they can earn at least 15 times more Trusted Source E-waste mining could be big business - and good for the planet Many millions of tonnes of televisions, phones and other electronic equipment are discarded each year, despite them being a rich source of metals. But now e-waste mining has the potential to become big business. www.bbc.com than if they gathered the same amount of regular plastic. This economic benefit also empowers these workers socially, putting them in charge of their own destiny.

Organizations like this can help to propel the 3D printing industry into a more sustainable and eco-friendly future.

3D printers have changed the way we use plastic. These innovative machines can take a small piece of filament and transform it into a replacement part for a motor, a piece of jewelry, furniture, novelty items, and so much more. Unfortunately, since so many people are new to the concept, many 3D printer owners dispose of a lot of plastic waste as they are practicing making their designs perfect.

When all that plastic from failed 3D printer attempts ends up in our landfills, it can take many years to decompose. That is why recycling 3D filament plastic is so important.

Keep in mind that when using a 3D printer filament recycler, you do not need to mix the different filament types. It could lead to poor printing results when you reuse it. Also, you should make sure the filament or plastic you are using has been separated and that it is clean. You will always get better results when you reuse 3D printer filament made from the same chemical compound. If you are interested in purchasing a 3D printer in the future, it’s crucial that you learn more about recycling 3D printer filament.