There are numerous hurdles that 3D printing experts may encounter. The main sign that your print has some complications is when you notice a ghost of layers on your models. This may ruin your efforts and turn out to be frustrating based on the time and energy spent in the print.

Though there are numerous complications that you may face during printing. 3D printer ghosting stands out to be a prototype. It also has multiple other names, such as ringing, echoing, and rippling. Most people, including seasoned experts, may face the problem more than once in their careers.

However, a number of factors may cause ghosting, among them being faulty machines. You can check the best ABS 3D printers that are versatile and easy to use to aid in mitigating such problems. This article has articulated all you need to know about how to get rid of ghosting in a 3D printer, how to detect it, and possible measures to attenuate it.

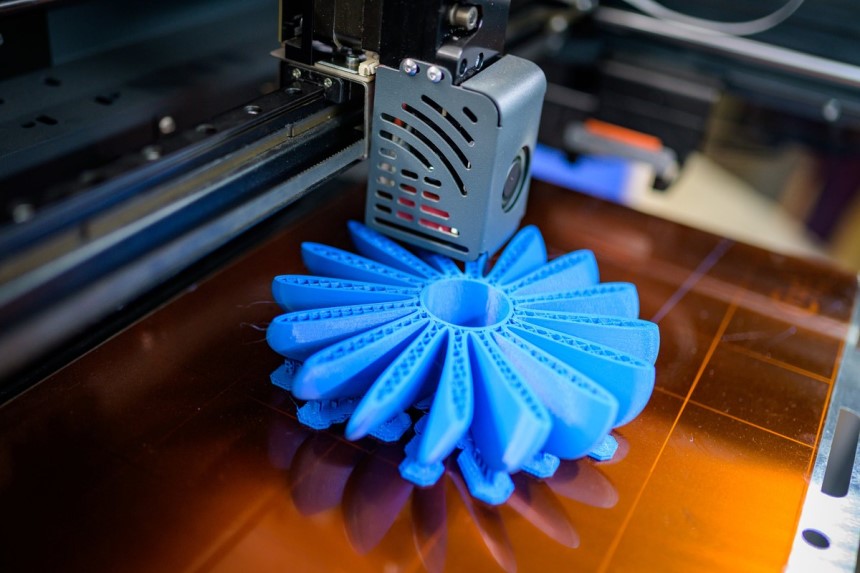

3D printing is a wide scope that utilizes computer-aided design (CAD) to produce three-dimensional objects. The technology dwells on layering techniques which is also referred to as additive manufacturing. It involves layering materials such as plastic to invent products with varying shapes, sizes, colors, and rigidity.

A 3D printer is used to execute such activities. They imitate the conventional inkjet printer-albeit in 3D. It majors on merging top-of-the-line software, powder-like materials, and accurate tools that design a three-dimension model from scratch.

These printers work from the ground level, where they pile up layers of materials to develop a three-dimensional object. Printers have impeccable flexibility as they can print numerous designs while using a wide range of materials. They are applicable in printing rigid materials such as sunglasses, phone cases, among others.

Some printers are superior in that they may utilize carbon fiber and metallic powders to develop extremely strong industrial products. They are vital in several industries across the globe, and they have dictated a promising future.

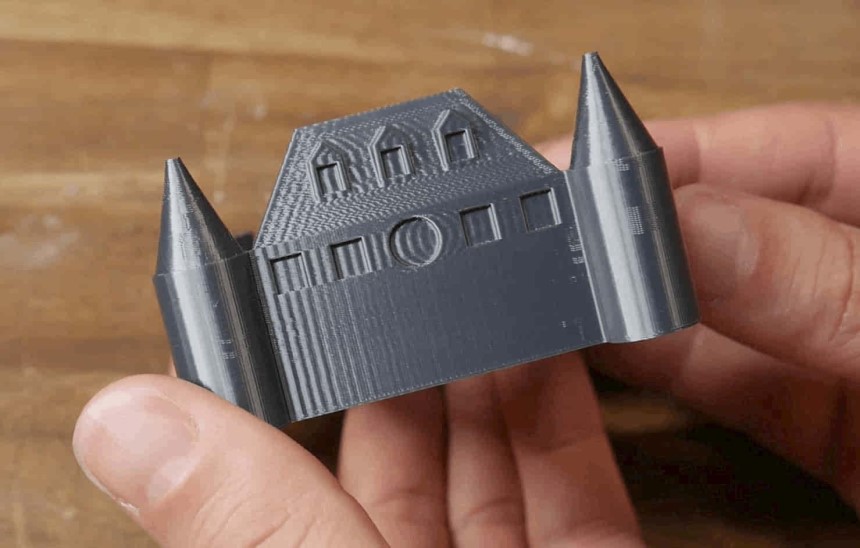

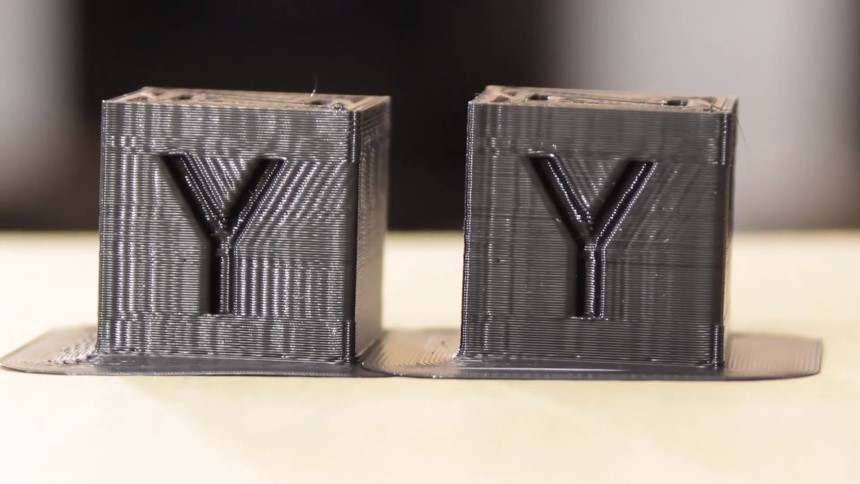

Ghosting is a common hurdle that occurs during printing. The most distinguishing feature that can help you identify ghosting is the appearance of structures and features not designated in the model. Mostly, it appears as duplicates of the model. Hence, when you view your model from a certain dimension, you will observe repetitive lines and features.

Ghosting does not affect the entire print. Some places will be in the desired condition while other regions will not be pleasing.

However, it will all distort the expectations of the final model. It is more common in models that are more complex such as wordings or logos.

Printing professionals always yearn for a sleek final product. Nonetheless, ghosting distorts such expectations as it creates unintended features on the model. You may notice absurd images and patterns on the finish, whereas a typical 3D print should have clean overlapping layers.

Some prints may be highly prone to ghosting. This includes small models and prints with sharp and numerous corners. You can unleash the effects by printing a large surfaced model, making it easier to detect such effects. The Tevo Little Monster is ideal for such prints. It has a large print volume that can accommodate 340m diameter and 500mm height.

Additionally, put your image in such a way that light will shine on the areas you suspect to have experienced ghosting. This will help you identify waves, circles, and funky shapes on your model. You should differentiate between ghosting and possible imperfections. Such include visible infills that occur when lines and patterns of your internal support system get printed on your model. The best way to distinguish the two is that ghosting causes recurring patterns near certain features in your print.

You may also download the Ghosting test, which aids in precise ghosting detection:

Numerous factors may cause ghosting during printing. Vibration is the preliminary concept in ghosting and happens due to the following:

Printing at top speeds is likely to be a major cause of ghosting. This is because high speeds spike vibrations in your machine, which is not likely to happen at fair speeds. These vibrations cause recurring lines, shapes, and patterns due to the movement of your device.

Not all 3D printers were designed to work on complex models that have numerous acute angles. In reference to material extrusion troubleshooting by MDPI Trusted Source An Overview of Material Extrusion Troubleshooting | MDPI Material extrusion (ME) systems offer end-users with a more affordable and accessible additive manufacturing (AM) technology compared to other processes in the market. www.mdpi.com , shapes, letters, and logos with numerous twists and turns can cause ghosting. Printers that do not match up the required quality may disappoint and lead to the development of weird shapes and patterns on your model.

The FLASHFORGE Creator Pro Dual Extrusion 3D Printer has the precision and cutting-edge customization required in developing quality prints. This will highly mitigate the potential risk of ghosting in your models.

Furthermore, some printers have not been developed with the efficiency required in producing accurate dimensional prints. Hence, you are likely to encounter periodic ghosting while printing.

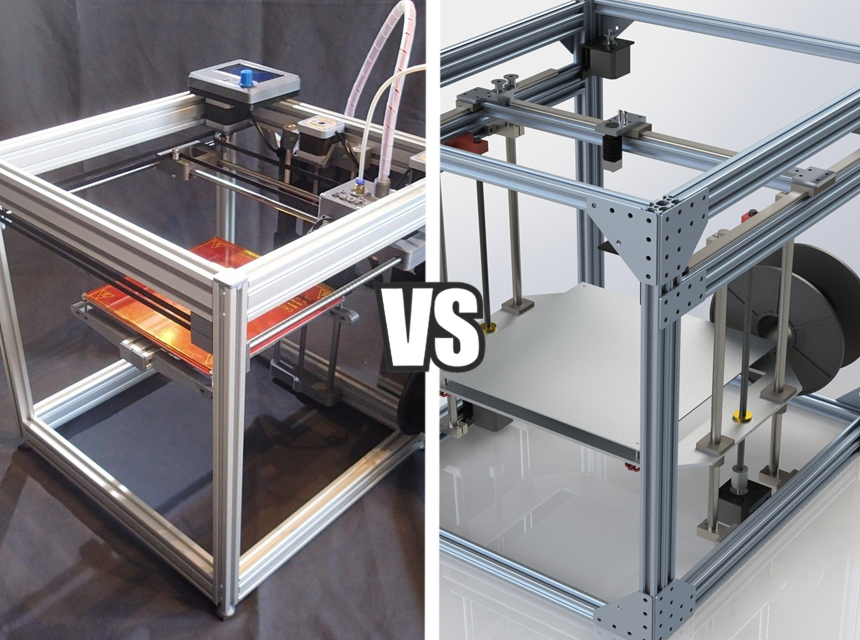

Printers are structured with different frames that are stipulated to work on different materials. Some materials have attributes that may withstand the vibration and motion that occurs during printing. A good example is the aluminum material which has the outstanding sturdiness to withstand vibrations during printing.

Nonetheless, this does not apply to all materials, which may cause ghosting in some models. Temperature is also a paramount concern that may reciprocate ghosting. Distinct materials have different capacities for withstanding temperature changes. In case the material is prone to melting, the vibrations will cause extreme ghosting on the model.

There is a difference between acceleration and jerk value. Acceleration is defined as how fast the printing speed changes. Jerk value is defined as how the acceleration alters. Nonetheless, they all have an impact on the development of ghost lines.

When the jerk value is higher, there will be sudden and quick movements. This will lead to less time for your print to settle, developing lines and unexpected patterns. On the other hand, a lower jerk value also has some notable downsides. It may cause unnecessary details on your model. This happens because the nozzle spends too much time on the model. It may also cause over extrusion in acute angles. Reducing the acceleration also mitigates ghosting as it reduces the printing speed, which reduces the moment of inertia.

After understanding the root cause of the problem, you may be wondering how to fix ghosting in a 3D printer. There are several mechanisms that can be deployed in solving 3D printing ripples. You can design solutions based on the contemporary situation that is causing ghosting. They include:

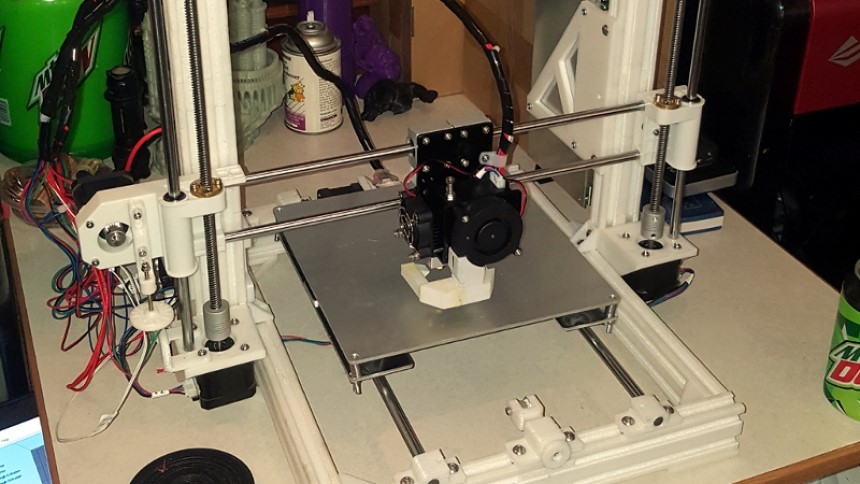

Hence, it is advisable that you conduct several checkups after using your printer over. This will ensure that you locate the areas and screws that cause wobbling during the printing process. There are a few more techniques that can reinforce sturdiness on your printer:

When the printer belts are loose, there is a high probability of sloppy 3D prints. This results because the full effect of the movement is not transferred from the stepper motor to the axis. Hence, it displaces the nozzle, which may cause ghosting.

It is recommended that you regularly check and tighten the printer’s belts to improve the print quality of your models.

There are several options to curb such menace. You can undo the belts and tighten them afresh, or print a belt tightener and clip it on the belt. The main principle is that you should not allow your belt to be sagging.

There is a lot of movement during the printing process. Thus, your printer is subject to vibrations that loosen some of the nuts and joints in your frame. Some may be unnoticeable due to long hours spent during printing and maybe a major cause of 3D printing ripples.

It would be best if you occasionally counterchecked the joints in the frame to ensure that there will be no unnecessary movements during printing. In case you notice any, tighten down the corner brackets, bolts, and rails. You can also follow up by giving each bolt a small turn to confirm that they are up for the task.

If the frame is still shaky yet all the joints are tightened, you can deploy an external bracket to reinforce its strength. This mainly applies to 3D printers with extremely tall Z axes, which increases the chances of shaking. This will mitigate any possible movements and ensure that you have a seamless printing experience.

This is one of the top-tier solutions that can be used to mitigate 3D printing ringing. Despite having slower prints, it is a safer and easier mechanism to avoid the development of unexpected patterns. This is because a higher speed reciprocates more vibrations during the printing process.

Hence, minimizing the printing speed will reduce the moment of inertia. It is also effective in reducing high vibrations, especially in complicated models with acute angles. Such vibrations result from the print head making sudden movements to ensure that the angles are covered.

Thus, when the acceleration increases, it results in more intense vibrations, which directly leads to ghosting. The severity of ghosting may also be determined by the number and speed of quick turns made during the printing process. Though it is an ideal solution, it has one downside that you have to familiarize yourself with. The slower the printing speed, the more time it takes to print sharp corners.

You can alleviate such conditions by acquiring the best stepper motor drivers for 3D printers. These components have imperative roles in your printing process as they control the movement of the printer’s head and monitor the flow of the material from the nozzle.

Rather than mitigating 3D printing ripples, reducing printing speed can be essential in solving rough printing surfaces, noises during the printing process, skipping layer lines, distortion curves, and Z-wobble. There are also other numerous printing complications that may arise due to the inappropriate setting of the acceleration and jerk value.

As stated earlier, you can download a Ghosting test website, Thingiverse, which allows you to test for ghosting on your printer. You can scrutinize the PLA and the ABS using different temperature ranges.

The higher the temperature level in the extruder, the more the presence of a solvent. So the vibration alterations will be more dominant. Moreover, when slicing a model in your software, you should have significant concerns about the printer’s X and Y-axis. It aids in the precise determination of the orientation and ensures correct printing.

3D printing has become an essential element in the current world, and its usage projects to be unprecedented. According to Arjun A. Trusted Source Future of 3D Printing | ResearchGate How today’s 3d printing technology can be adapted to many other industries & scientific research? What alterations of a typical 3D printer are required to do so? www.researchgate.net from the Indian Institute of Technology Madras, numerous industries and scientific researchers invest in 3D printing. However, there are numerous complications, such as 3D printer ghosting, which may deteriorate printing quality. The primary cause of 3D printing ringing is the transmission of vibrations during the printing process.

There are also other numerous causes of 3D printing ripples, such as high jerk and acceleration values, insufficient frame rigidity, and the weak, shaky surface beneath the printer. Finally, several measures can be incorporated to attenuate such hurdles; they include ensuring that your frame is stable, adjusting appropriate jerk and acceleration values, tightening the belts, cushioning the printer, and placing your printer on a grounded surface.