3D printing has emerged as one of the most exciting innovations in recent decades. It made ripples in manufacturing, entertainment, education, and healthcare. That’s just a list of the most prominent and notable. There are endless ways that 3D printing has been used throughout the world. However, If it’s not working the way that it should, then it’s not as impressive. A world-renowned innovative technology isn’t immune to technical errors and mishaps. When a 3D printer stops for no reason, that’s a concern. Multiple potential problems can cause that, with a clogged extruder being one of the most common. When you work on a 3D project, you want your equipment to work. It’s as simple as that. There’s not much more frustrating than when a 3D printer stops extruding mid-print. It’s annoying, to say the very least.

Industries like automotive, environmental, healthcare, fashion, radiology, and so many more have used 3D printing. Did you know that 3D printing has been used in creating durable and solid robotic hands in yale laboratories? What about the fact that NASA Trusted Source NASA's Perseverance Rover Bringing 3D-Printed Metal Parts to Mars Instead of forging, molding, or cutting materials, 3D printing relies on lasers to melt powder in successive layers to give shape to something. Doing so allows engineers to play with unique designs and traits, such as making hardware lighter, stronger, or responsive to heat or cold. www.jpl.nasa.gov has used 3D-printed metal parts to bring to Mars?

There are many different reasons why a printer can stop printing mid-projects. Most likely, if it simply stopped printing with no warning, then it was due to an issue with the extruder. If you happen to hear a clicking sound, that may be an entirely different problem altogether. The clicking hints that it may not be the extruder being clogged but instead the extruder skipping steps and stops.

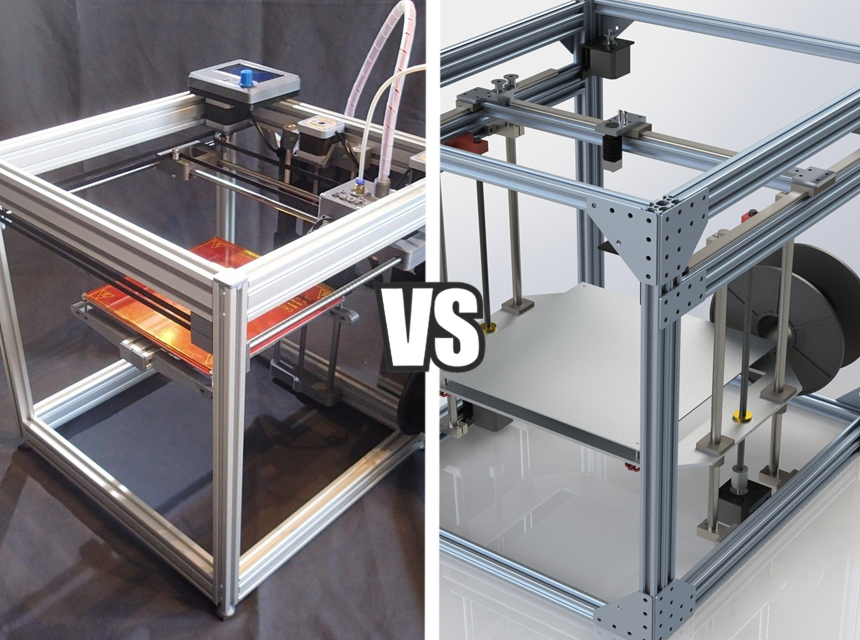

If this is a problem that continually persists, it may be time to look at an upgraded machine. Many different brands provide high-quality printers such as Tenlog, FlashForge, Bibo, Raise 3D, and Qidi.

The simplest answer is that you’re out of filament. 3D printing filament is a kind of thermoplastic material used for creating 3D models Trusted Source How It Is Made: 3D Printing Filament | Make: The biggest misconception about filament production is the nozzle. Most people assume, like we did, that the machine would work just like a giant filastruder. It would push molten material out of a nozzle at the right diameter, which would then be wound onto a spool. Heck, even standing in front of the machine you may think that is what is happening! makezine.com and items. These filaments can be as small as 0.25 mm and as large as 2.85 mm. It may seem obvious, but sometimes it’s difficult to notice the spool has run out. Give it a check to know what the next best step is.

Even some of the most reliable, the best value, and premium choices for nozzles can become clogged. Typically the higher quality is, the less likely an obstruction is to occur.

Like with any machine, overheating can throw a wrench into the whole machine. Overheating the motor driver for the extruder means that it’s not completely working. With 3D printing relying on controlled and stable temperature, this is an issue. The problem could be an overheated extruder motor driver. When it’s overheated, it doesn’t work the way it should. IT can and does miss steps and can lead to a clogged nozzle. If this is the case, you’ll notice random and erratic stepping coming from the motor.

3D printing has the potential and the history of changing industries for good Trusted Source The Future of the Alternative Investments Industry | HBS Online When the public markets crashed, individuals who had previously heavily relied on traditional investments saw the value of their investments plummet, leading many to look into the world of alternatives. Alternatives tend to have a low correlation with traditional assets, meaning they trend in opposite directions. This makes them wise additions to the portfolios of investors who are looking to diversify, spread out risk, and increase returns. online.hbs.edu . But that doesn’t mean that things don’t go wrong here or there. When something goes wrong with 3D printing technology, sometimes it’ll simply delay a product. Sometimes it can render the printer completely useless. But don’t worry, the printer isn’t beyond all hope or repair.

Don’t fret about replacing your machine just yet. If you need to, however, make sure you get a 3D printer that can handle the temperatures required for your needs.

If your filament is out or no longer connected, it can cause a major problem. This can be a simple fix by just reinserting the desired filament material. The ideal solution for this is to merely fill it up again.

Adjusting the gear spring tension and filament tension can help eliminate issues when you store the filament. This ensures that the filament is in peak condition for peak performance. It eliminates the risk of tangles, rips, tears, and bends that can impact the end product or clog the extruder nozzle.

When it comes to heating the filament, each material has a different temperature range. Printing at too low of a temperature will have no extruding at all. However, if it’s needlessly high, it can be counterintuitive. Printing at too high of a temperature can make the filament vitrify or convert into something much more glass-like.

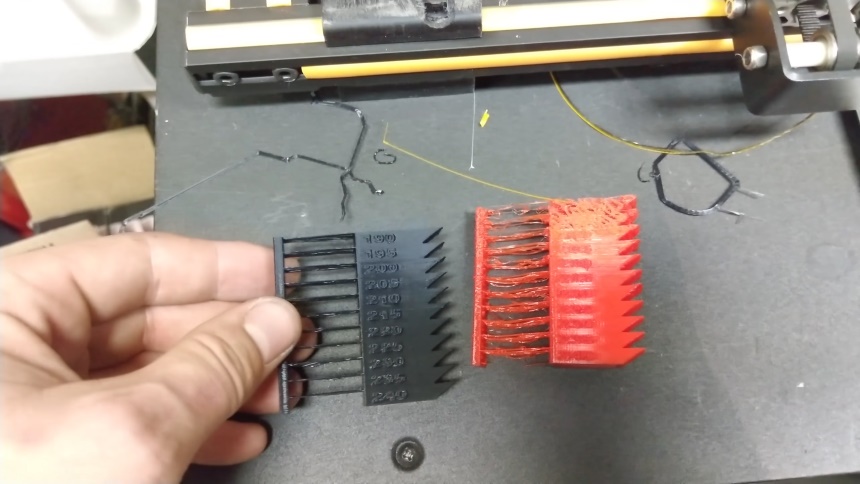

None of those options are ideal. The best course of action is to always check the optimal temperature for the filament based on the manufacturer. This can be a bit overwhelming with how many different filaments there are out there. Here are a few suggestions for temperature settings for some of the leading filaments. These are just suggestions, and the manufactories manual will be able to give a bit more detailed explanations for your use.

| Type of Filament | Print Temperature (°C) | Bed Temperature (°C) |

| PLA | 180 – 230 °C | Not Required or, 60-80 °C are recommended also |

| ABS | 210 – 250 °C | 50 – 100 °C |

| PETG | 220 – 235°C | Not Required |

| TPE | 225 – 235°C | 40 °C |

| TPU | 225 – 235°C | Not Required |

| Wood | 195 – 220°C | Not Required |

| HIPS | 210 – 250°C | 50 – 100 °C |

| PVA | 180 – 230 °C | Not Required |

| PET & CEP | 220 – 250 °C | Not Required |

| PLA Metal | 195 – 220 °C | Not Required |

| Lignin | 190 – 225 °C | 55 °C |

| Polycarbonate | 270 – 310 °C | 90 – 105 °C |

| Wax | 170 – 180 °C | Not Required |

| PETT | 235 – 240 °C | Not Required |

| ASA | 240 – 260 °C | 100 – 120 °C |

| PP | 210 – 230 °C | 120 – 150 °C |

| POM | 210 – 225 °C | 130 °C |

| PMMA | 235 – 250 °C | 100 -120 °C |

| PC-ABS | 260 – 280 °C | 120 °C |

The best solution for this is to unclog the extruder. Consider this like when playdough gets stuck in the playdough creators and stencils. There are typically three options to manually clean the clogged nozzle.

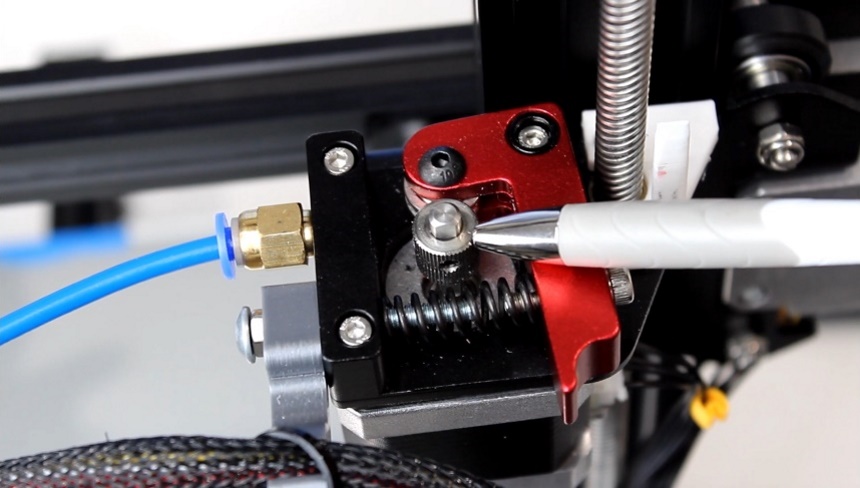

Pushing the filament material manually through the extruder can help. Start by making sure the end is fully heated. Then take the extruder arm and squeeze it to compress the spring. Push the filament gently and watch for it to come out the other end.

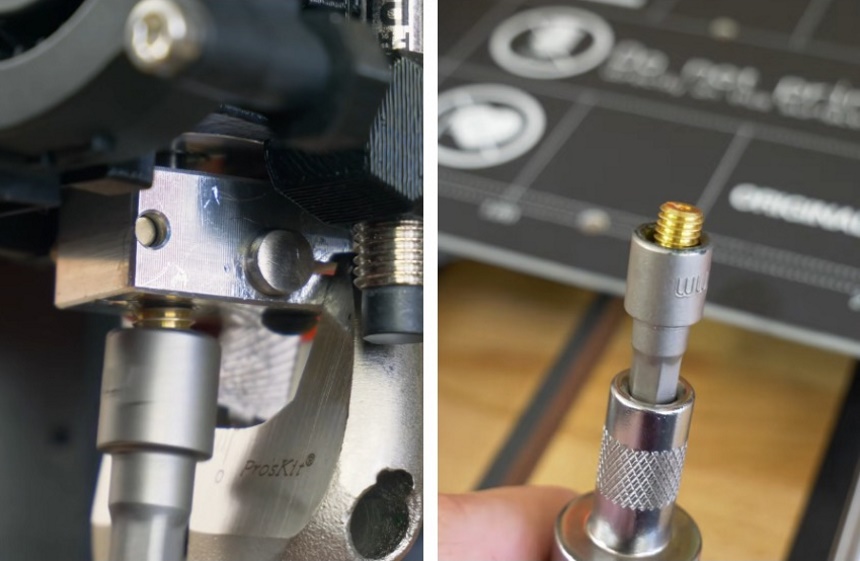

This can be done with an acupuncture needle, a guitar string, or anything small enough to enter the extruder’s hole. Do a test to make sure that everything can go through easily.

This is also known as the atomic method. This works the best with thermal resistance filaments such as ABS or nylon. A cold pull is another option that requires the machine to be completely cooled throughout the process. To start, heat up the nozzle to 220°C and manually push it manually as hard as you’re able to. From there, let the printer cool down while keeping the pressure.

When the printer reaches approximately 90°C for PLA or 160°C if you’re using ABS, swiftly and vigorously remove the filament. Repeat this until the filament comes out completely clean.

This is a good time to take a pause. It is letting your machine cool down. The solution is to simply let the machine cool down or to swap it out with a new cold part.

Broken nozzles do happen. IT sucks when it does. When it comes to nozzles, at times, they get warped, damaged, or simply wear down. What happens with many internal components, unfortunately with continued and prolonged use. Consider replacing the nozzle with models that can be easily shifted, changed. There are many options that can provide multiple nozzles of varying sizes. Read through the features and specifications for each nozzle to make sure it is compatible with your printer, filament of choice, and 3D printing needs.

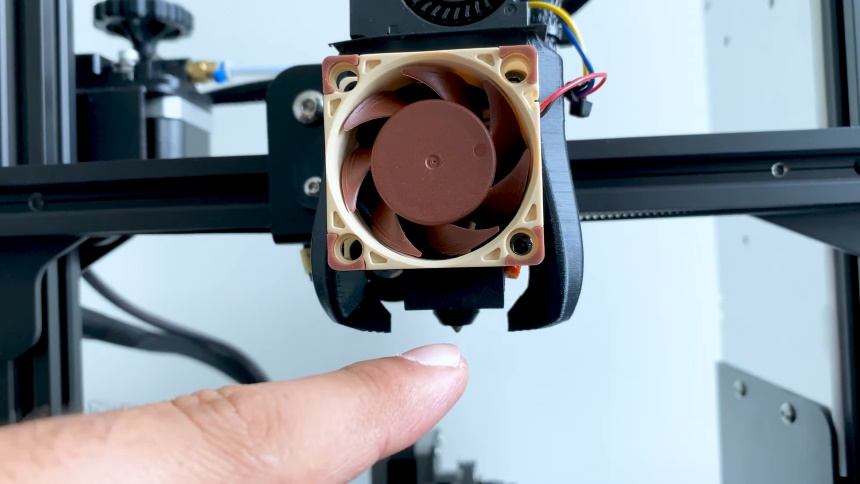

Nobody wants a clogged nozzle to become a routine. It’s frustrating enough to fix it the one time. Once it’s fixed, it’s important to prevent this issue from happening frequently. With the cost of 3D printers ranging in the thousands, it’s important to make sure this printer can last for years to come. With proper maintenance, usage, and cleaning it’ll be able to withstand the tests of time. Proper equipment and additions are also vital. PTFE tubes and HotEnd fans are two examples of components that can help avoid extruder obstruction. Proper settings such as temperature, speed, materials all contribute to a well-running machine. The 3D printer has specifications such as this for a very good reason. These settings make it run efficiently and optimally.

When you reduce the printing speed, you’re able to make sure that everything comes out the way it should. This isn’t always the best for the filament or the product. Make sure to check the suggested settings on your filament. Each material has slightly different features. Thus the temperature and suggested speed are different for each model.

There are many different options for filaments, depending on what you’re looking for in an end product. Flexible filaments such as TPE and TPU can easily jam the extruder. Having high-quality filament can help eliminate a wide range of problems before they start. Lower quality materials tend to be, well, lower quality. They don’t quite stand up under the combined heat and pressure. That means that it’ll cause more and more problems for the 3D artist and 3D printer.

Hot End fans are an important part of the printing process because they assist in keeping the filament at a stable temperature before being heated by the heating block. The hot end fan requires to be clean and maintained to avoid clogs and obstructions.

This is another important aspect that some creators don’t think about. PTFE is a common component in 3D printers relying on filament materials. The PTFE tube is specifically the white tube that’s used to guide the filament towards both the extruder and the heated end. Not all 3D printers use this. Any printer using a direct extruder doesn’t require this kind of tube. The PTFE tube, when it’s not working properly, can under extrude the filament. Our advice would be to upgrade your PTFE tube that can withstand higher temperatures. When it’s not working properly, it can impact the whole process.

Cleaning the mechanics of a printer regardless of what kind is important to keep the machine running well and longer. Maintaining a 3D printer can be hard, but it’s worth it to save your investment. This requires everything to be disassembled, cleaned, and cleared out. As a result, all the loose plastic, filament, and dust will be removed.

3D printing is a way to bring your imagination to life. If it’s not extruding the material, it’s not doing the first step in 3D printing. That’s not going to help you with your artistic creations. Don’t stop creating just because of a faulty extruder nozzle. When a 3D printer stops extruding mid-print, there are a few potential problems; clogged extruder, out of filament material, and overheated machinery. There are several solutions to fix it at the moment, as well as long-term solutions to limit it in the future. This is your creation, make sure that it’s up to your preference and standards. With this informational article, you have all the tools and information needed to Get back to 3D printing the long list of projects.