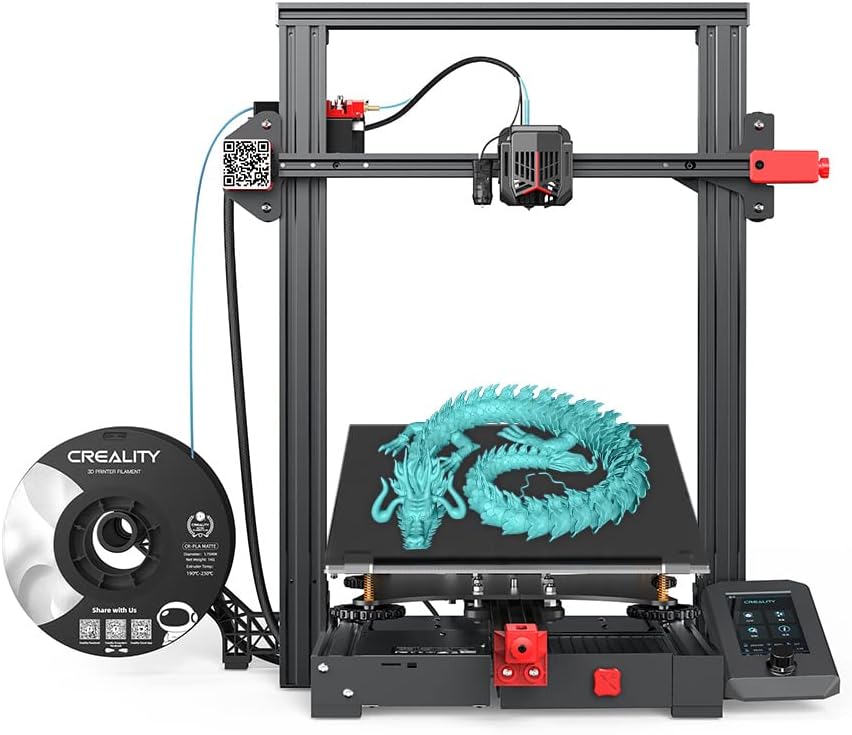

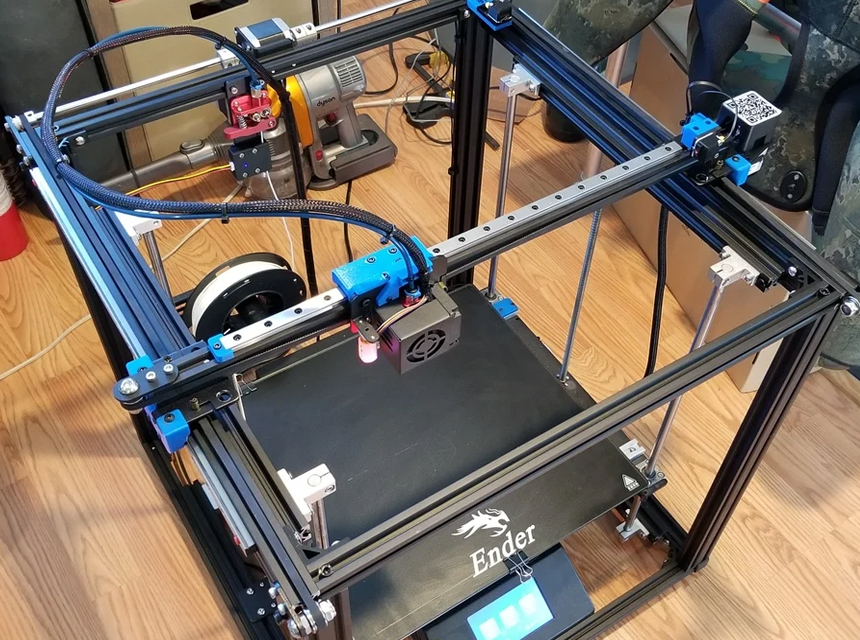

Creality is a prominent dealer in the production of 3D printers that offer great value at budget-friendly prices. The Ender 3 Pro and Ender 3 V2 are upgraded versions of the most prominent printing machine, the Ender 3. They have high ranks in the 3D printing industry as they can print a wide array of materials and can execute at vast print speeds.

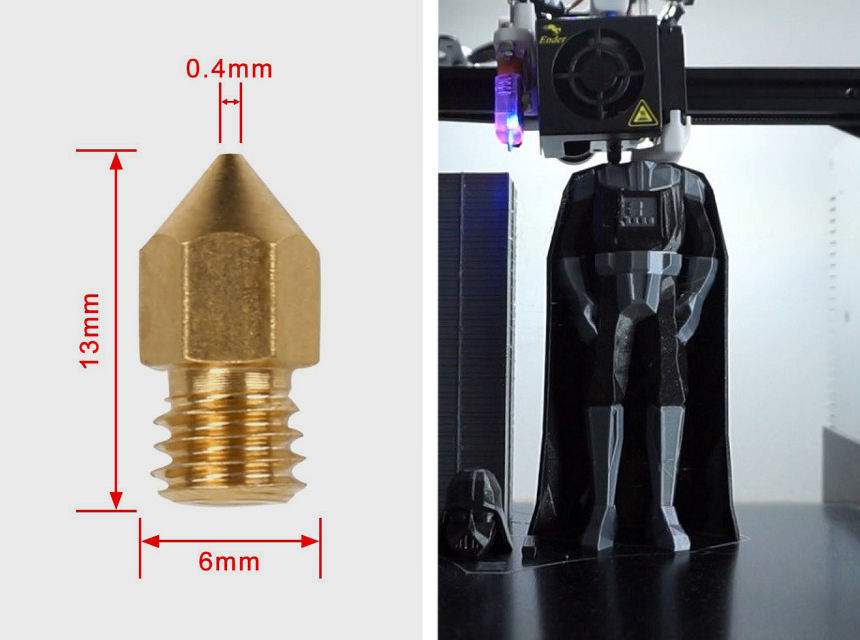

The Creality Ender 3 V2 3D Printer is the most recent version customized with an updated motherboard that allows silent printing operations. What is Ender 3 nozzle size, do you ask? Printers from Ender are fitted with a 0.4mm brass nozzle which utilizes the MK8 hot end configuration. This is because it demonstrates simplicity and efficacy during the printing process.

You can enhance the performance of your printer by equipping top stepper motor drivers in your machine. It monitors the movement of the printer head and provides adequate power. Read on to discover more about Ender 3 Pro and V2 nozzles and how size affects the printer’s performance.

Ender 3 Pro and V2 are successors of the Ender 3 and have been customized with upgraded features to suit better performance. They come with a standard nozzle size which can be changed to a higher value based on printing preferences. However, some merits and demerits accompany such alterations, as discussed later on in this article.

These printers’ nozzles have been made using brass. It is an ideal material that offers impeccable services in regular printing. It is pocket-friendly, easy to shape, has high heat conduction ability, and has low corrosion probability. Hence, it can serve in numerous printing activities, particularly in high-heat applications.

Nonetheless, brass has a downside in that it is comparatively soft. This may result in damage by come types of abrasive filaments. Its application is ideal for printing materials such as ABS, PLA, TPU, and PETG. It delivers top-notch results and can serve you for a substantial period. This may apply to 3D Printers for Miniatures specified for hobbies and business printing purposes, such as creating mini models and architectural models. However, a recent study Trusted Source Research on precise control of 3D print nozzle temperature in PEEK material | ResearchGate PEEK (poly-ether-ether-ketone), as a typical high-performance special engineering plastic, become one of the most excellent materials to be used in 3D printing technology because of its excellent mechanical property, good lubricity, chemical resistance, and other properties. www.researchgate.net by Gong Wang, Yu Huo, among other authors, stated that temperature ranges determine the nozzle material you choose.

Based on an analysis by ResearchGate Trusted Source Analyzing the effect of nozzle diameter in fused deposition modeling for extruding polylactic acid using open source 3D printing | ResearchGate The 3D Printer has been widely used in the fabrication of 3D products. One of the main issues has been to obtain a high quality for the finished parts. www.researchgate.net the nozzle diameter has a notable effect on the performance of a printer. Ender 3 Pro nozzle size and Ender 3 V2 nozzle size is a standard diameter of 0.4mm, ideal for numerous printing tasks. It can be deployed in delivering layer heights with a print speed range from 0.12 to 0.24, while some printers can accommodate up to 0.32mm. When it goes beneath 0.12, less plastic will be extruded. This may result in numerous holes in your model and unfinished layers. Moreover, this nozzle size minimizes clogging as a large portion of particles will pass through.

Based on specific printing requirements, you may change the nozzle size to conform with current needs. The Creality Ender 3 Pro 3D Printer supports numerous nozzle sizes for printing tasks. But keep in mind that despite the possible advantages, there will be some downsides accompanying such tweaks. Let’s look at the effects that come along with adjusting the size of the nozzle size.

After understanding what size nozzle comes with Ender 3 V2, you can decide whether to use larger ones or not. Larger nozzles are preferred when printing models with larger layers. The final product will also have stronger layers. However, the model will lack an appealing view as compared to one with smaller layers. A larger nozzle will also function efficiently at higher speeds. For instance, a 0.4mm will print twice more than a 0.2mm nozzle size.

Additionally, using larger nozzles than the standard Ender 3 stock nozzle size reciprocates the amount of heat that the hot end produces. When you use a higher Ender 3 nozzle diameter, you should have a hot end that demonstrates utmost efficacy in melting the plastic. Hence, you may be required to minimize the print speed to keep the plastic flowing.

Conversely, you may choose to change the hot end and utilize one constructed using pure metal. This is because hot metal ends are attributed to intense heating elements. Thus, it will sustain continuous heat that will ensure that the plastic is constantly flowing. The table below summarizes the advantages and disadvantages of using larger nozzles for 3D printing.

| PROS |

CONS |

|

|

A smaller Ender 3 nozzle diameter provides excellent resolution. The smaller the layer height, the less you will notice any layer lines on your model. Professionals who yearn for a top-notch finish should dwell on smaller layer heights.

You can also use small nozzle sizes to print models that have fine details. This includes models with thin beams and wordings that may require utmost precision. Using small layer heights will ensure that the finer details are printed in your model. There is a high probability that such details will be eradicated by the slicing software in large models.

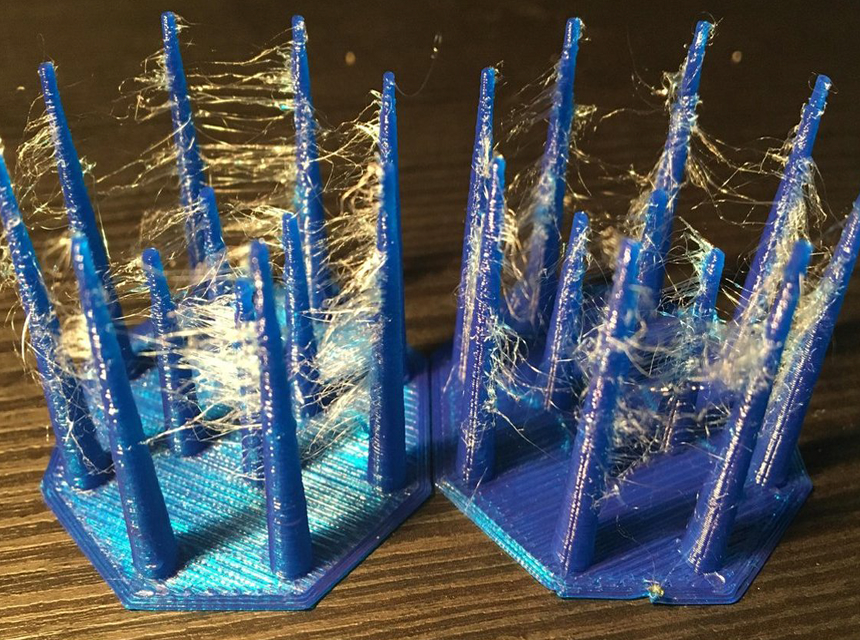

Nonetheless, small size nozzles are relatively slow. Also, incorporating high resolutions will result in a slower printing process. Large nozzles sizes have enough space where particles can fall off and mitigate clogging. The use of small nozzles will highly result in clogs. This is because they lack adequate space where falling particles can pass through. Hence, tiny dust particles are likely to be a menace during printing.

You can attenuate such possibilities by using high-quality PLA. Additionally, printing a filament cleaner can ensure that your printing is clean. Here are the advantages and disadvantages of using a smaller nozzle size for 3D printing.

| PROS |

CONS |

|

|

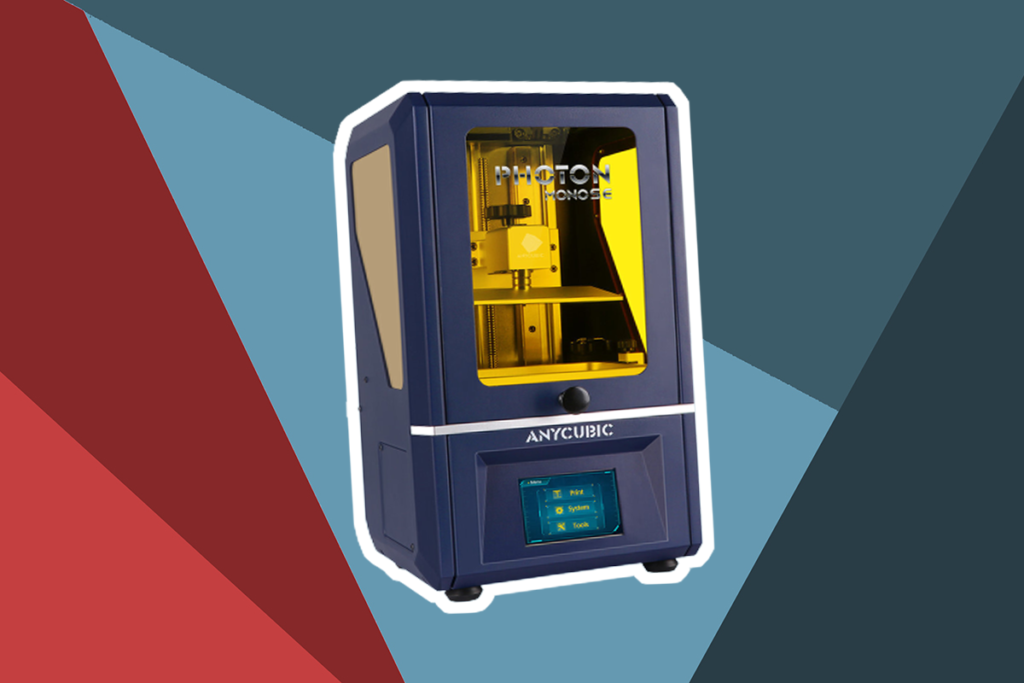

3D printing is a wide scope that may require upgrading from a brass nozzle to other nozzle materials. This may be in an attempt to print other exotic materials. Hence, a nozzle made using all-metal can be essential in such circumstances.

This is because some models require high-temperature filaments to execute appealing tasks. There are numerous alternatives for high-temperature or abrasive filaments. Such materials include stainless steel, nozzle X, carbon steel, A2 tool steel, and copper with sapphire ruby. These materials will endure the wear and tear likely to happen in an ordinary brass nozzle.

Some printing works do not only depend on the type of nozzle material that you use. Thus, you may be required to upgrade the whole hot end to meet the heating requirements.

Individual Material Attributes:

There are numerous aspects that 3D printing requires for a successful operation. Also, different printers have been designed with attributes that can function in discrete roles. For example, there are 3D printers for architects that enhance uses, such as prototyping to building models, among others.

The Ender 3 nozzle size is also an imperative concern during the printing process. This is because it determines the speed during printing, quality of the final model, and operation mechanisms when printing. In the above article, we have explained crucial information regarding the use of different nozzle sizes and how they influence the performance of your printer.

Another factor to consider is the material of your nozzle. Brass is the common material fitted in Ender 3 Printers due to its excellent heat conductivity. However, some printing tasks may require the use of a different material due to intensive heat conditions.