According to the Guardian Trusted Source Is 3D printing about to hit the mainstream? | 3D printing | The Guardian The technology for 3D printing is moving fast. One day every home may have one www.theguardian.com , 3D printing technology is about to become mainstream, and it’s not hard to see why; it guarantees rapid prototyping and gives you the flexibility of designs. The mechanism of a 3-D printer is pretty straightforward; hot filament is extruded onto the print bed through the nozzle. There are, however, instances where the molten filament gets stuck, making extrusion difficult.

If you’ve been in such a situation, then you know how annoying it can get. What causes filament sticking to nozzle? How can you prevent this from happening? We have compiled a comprehensive guide just for you! With so many 3D printer models on the market these days, it can be tricky to determine which one is right for your needs. If you’re looking for recommendations, we put together a list of the best 3D printers based on factors like print quality, speed, and overall value.

There are various reasons why the filament sticks to the hotend, but the most common ones include;

Proper adhesion is highly dependent on how clean the print bed is. Any residue, oils, or dust particles need to be removed before you start using your 3D printer. We advise that you use gloves when mounting your glass hotbed on the printer because fingerprints can also interfere with the adhesion of the hot filament.

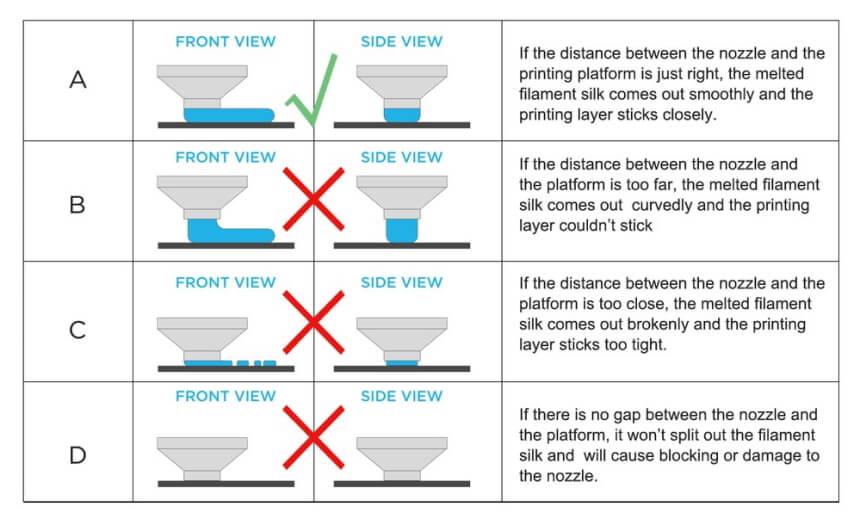

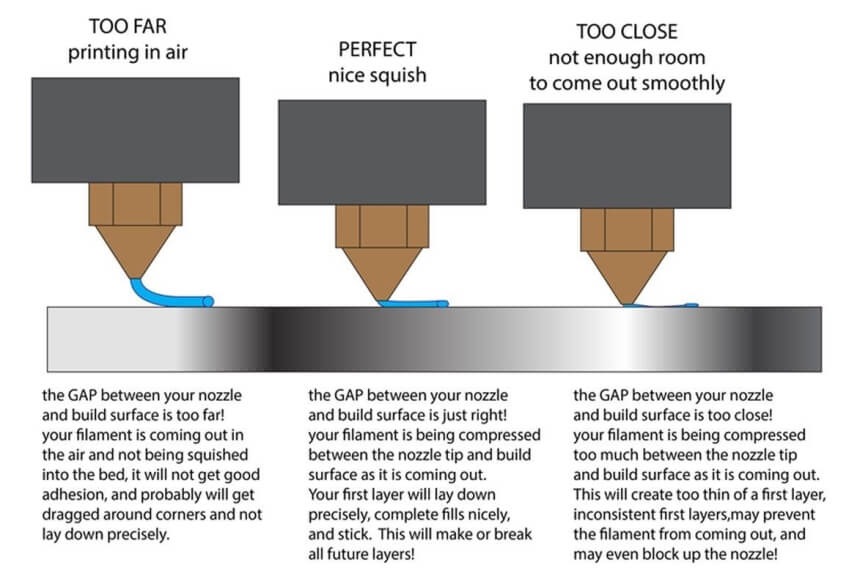

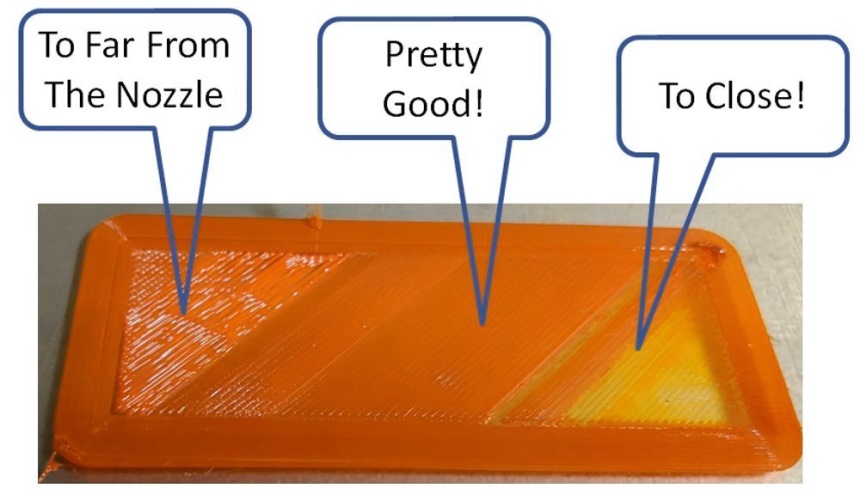

This is one of the most common causes of the filament sticking to the nozzle. Generally, the print bed’s Z-offset should be around 80% of the nozzle’s diameter. This is the perfect size for the nozzle to fully extrude the filament instead of dragging it around.

If you notice that the distance is too high, you should give your printer a mechanical push or lower the nozzle gradually until it starts functioning properly.

Even though the filament sticking to the nozzle is frustrating, there is a silver lining. It mostly occurs at the beginning of your printing project, so you can easily solve the problems. This ultimately reduces time wastage and the amount of material you would have used. If the first layer of your printing project fails to stick, here are the top solutions.

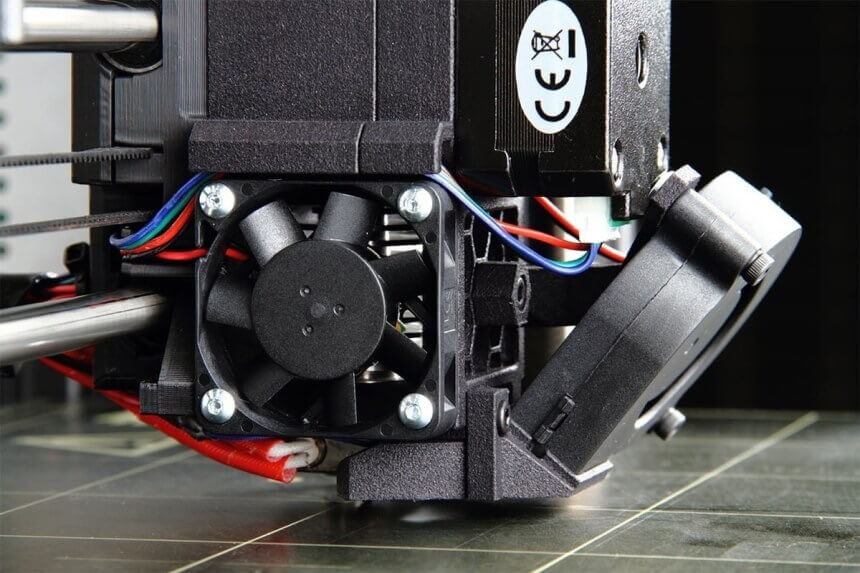

Based on popular opinion, one of the best 3D printers with a glass bed is the Creality Ender 3 V3. it has a silent printing feature and offers a more stable and faster performance. This 3D printer also offers an effortless filament feed-in and can resume printing after power outages.

We recommend that you use warm soapy water and a soft piece of cloth to wipe the print bed. If this doesn’t work, use acetone on the stubborn stains. Don’t use the print bed until it’s completely dry.

If the 3D filament is exposed to low temperatures, it won’t melt evenly. The end result will be a dense material that will come out slowly or be difficult to extrude. If you experience filament sticking to the nozzle, increase the temperature gradually by 5 °C until the filament melts evenly.

This solution is especially effective if the filament is only sticking to the nozzle during the first few layers. You should, however, note that if the temperatures are too high, the filament will start stringing, so make sure that you maintain the optimal temperatures.

Gradually start adjusting the nozzle until it’s the optimal height from the print bed. Don’t forget to level the bed properly, either using an automatic leveling system or manually.

When the print bed temperatures are high, the filament will have an easier time sticking to it. If you’re using PLA material, this is not necessary, but it does make the process easier. When the print bed is heated, adhesion improves, reducing the chances of the filament from sticking to the nozzle.

If the filament is exposed to a sudden drop in temperature when it’s exiting the nozzle, there will be poor adhesion, which will then cause it to stick to the nozzle. This is why you should try to slow the cooling for the first layers by turning off the fan. There are instances where you have to print your project with an enclosure on it. This prevents the first few layers from cooling quickly by preserving their temperatures.

The good news is that some printers come with an enclosed ensign, and based on popular reviews, the Dremel Digilab 3D45 is one of the best. It is perfect for tinkerers and hobbyists and is reliable and low-cost. You can print on it as soon as you take it out of the box, and it works for countless hours. This 3D printer also comes pre-assembled, so putting it together is easy, and it also comes with a 0.5kg spool of the best filament.

Make sure you calibrate the bed level before you begin your printing project. There are printers that come with an automatic leveling function, but most of the time, you have to do this manually. Start by fitting a piece of cardboard between the nozzle and all corners of the print bed. Make sure it fits snugly in all places, i.e., it’s not too tight nor too loose, and adjust as needed.

The difficulty of the adhesion is determined by the printing material that you’re using. For instance, Kapton tape and Blue Painters tape work relatively well. If they prove ineffective, you should consider high-duty tape for more adhesion. Most of these tapes are usually expensive, but some of them are reusable.

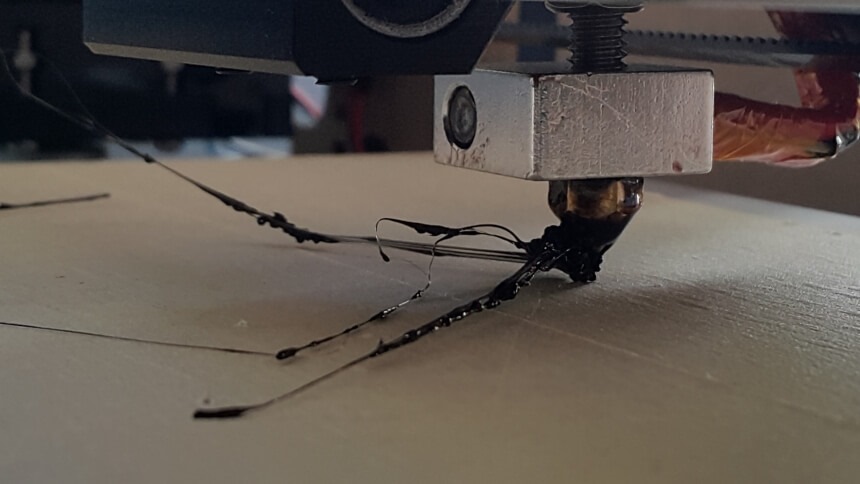

Nozzle blockages disrupt the flow of filament, which results in the feeder system experiencing a pressure buildup. This then causes extruder skipping and clicking.

The best way to tell that the nozzle is blocked is by checking how the filament behaves when it’s being extruded. If it starts curling around the top of the nozzle and its distance from the print bed is level, it’s most likely clogged.

There are 2 main ways of cleaning a blocked nozzle;

The components of most of the best dual extruder 3D printers are usually related, which means that if one area is faulty, it impacts your entire printing project. Inconsistent flow rates mean that there’s something wrong with the filament. Either the temperatures are too low, the print bed is not level, or the nozzle height is too high. There are also instances where the inconsistent flow is caused by the feeder rates being too slow or changing your printing materials. Make sure you adjust the flow rate when this happens.

Here’s a quick overview of how to solve various printing materials sticking to the nozzle.

According to the Washington Post Trusted Source 3D printing - The Washington Post Proponents hail 3-D printing as one of today’s most revolutionary technologies, even though mass adoption is still years away. Here’s how some firms are using the technology. www.washingtonpost.com , 3D printing may be several years away from mass adoption, but it’s one of the most revolutionary technologies. One of the major challenges that hobbyists face with 3D printers is filament sticking to nozzle, which can impact your printing project. We hope the above tips will help you fix this problem.