When getting into 3D Printing, it’s important to have a sturdy and durable wall to have great stability in your print’s structure. You don’t want your build to fall apart the moment the support is taken out. It’ll be a long process to get your piece up again before you can finally use or frame it. The strength of your wall depends on the type of 3D Printer Ink or Filament you have. Whether it’s colored, plain, or brought in a bundle, the filament is what dictates how long your print is going to be or how long it will last.

Minimum wall thickness in 3D printing basically means having the least possible filament thickness without losing the quality of your structure.

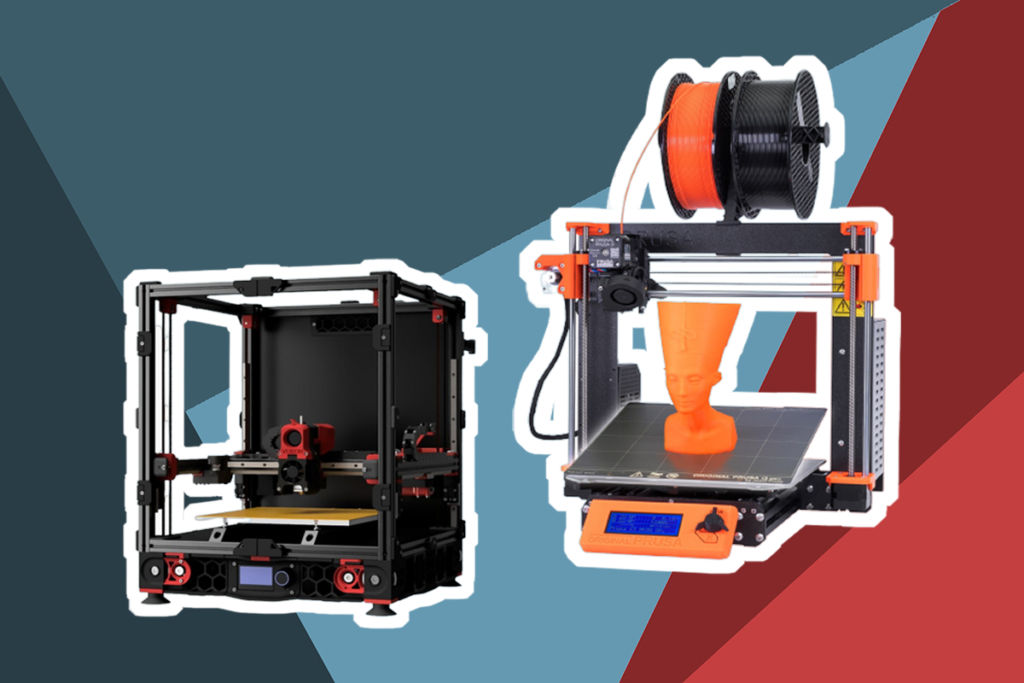

You are probably wondering just how thin can a 3D printer Trusted Source 3-D printing: the shape of things to come - CNN Three-dimensional (3-D) printers have come a long way from their 1980s origins as machines for building prototypes for industrial engineers and architects. edition.cnn.com print. Well, since they can technically only print one layer at a time, it will likely be a little thinner compared to the hard filament you have on stock. However, this initial print is weak and isn’t fully formed. You’ll need something strong to hold your print if you want it to be worthwhile. If the structure is too weak, it can result in the piece flopping to the side or warping on itself.

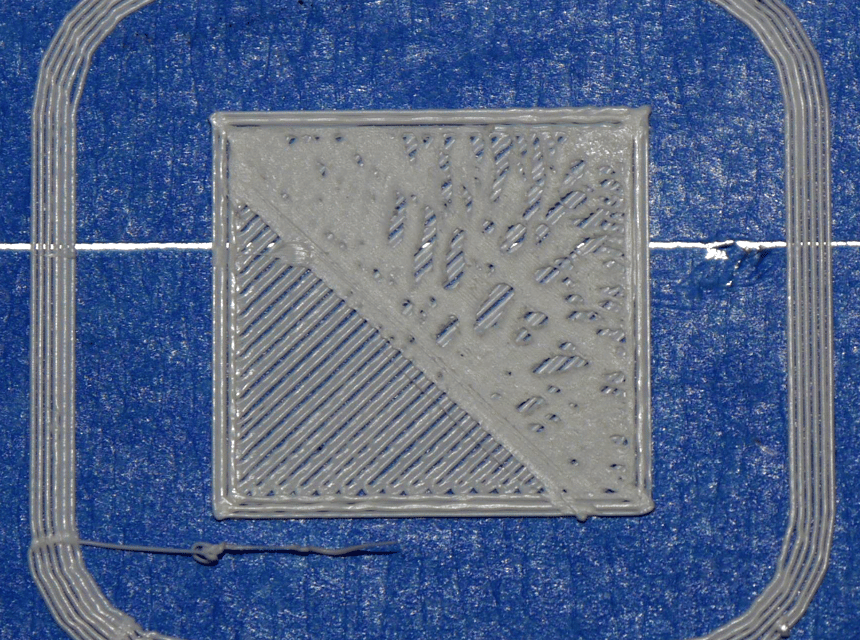

The general rule is that you cannot get lower than 0.7 mm. The recommended minimal thickness is 2mm.

Wall thickness can be calculated by going in-depth with your design. While it is true that having metal filaments will make your structure stronger, it is still safer to just make your wall design a bit thicker. However, if you really want to have thinner wall thickness without sacrificing your stability, you can study designs that can make your structure stronger than most. You can do this by having a better base and internal support within the piece.

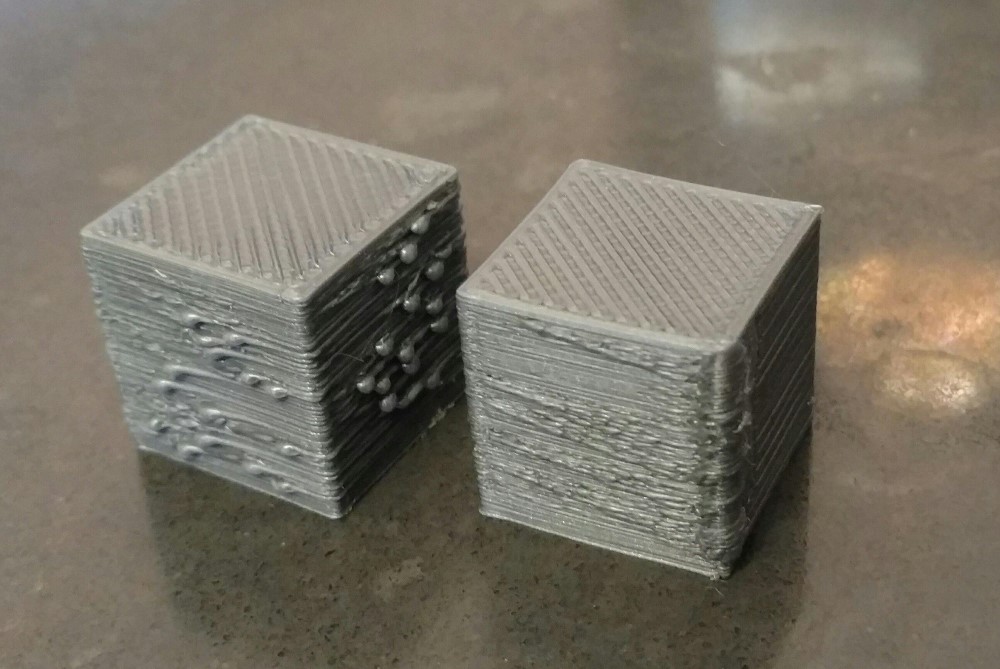

Learning the perfect dimensions and thickness in your design is a process of trial and error. There is no “one rule for all” in the art of 3D Printing. Yes, you can expand your knowledge in creating structurally sound designs Trusted Source Building by numbers: how 3D printing is shaking up the construction industry | Guardian sustainable business | The Guardian Robotics and prefabrication could see more 3D printers deployed on building sites but quality control remains a problem www.theguardian.com , but it’s not until you have printed it out you will be sure if it’s “right” or not. After all, your design may sound great on paper, but it’s still possible that it will fall apart upon a single touch.

How to Calculate Minimum Wall Thickness

How to Calculate Minimum Wall ThicknessDespite not knowing whether a design is completely feasible, there is still a way to at least try and figure out which sizes work with which. You’ll have to go through the structure of your design again, check if the printer can do your design. If it can, then congrats! You’re one step closer to printing.

If you are using Multicolor or any sort of strong metal during your process, it’s advisable to have at least 2 mm minimum wall thickness. Meanwhile, if your design features a Supported Wall, meaning that two walls are linked together, you can get away with having a wall thickness of 0.7mm. Those two are the general guidelines Trusted Source Minimum Wall Thickness for 3D Printing Understanding the minimum wall thickness for 3D printing will set you up for design success and lower your production costs. formlabs.com when fixing up wall thickness, though usually, everything else is interchangeable depending on your specific design.

Constantly check your minimum wall thickness

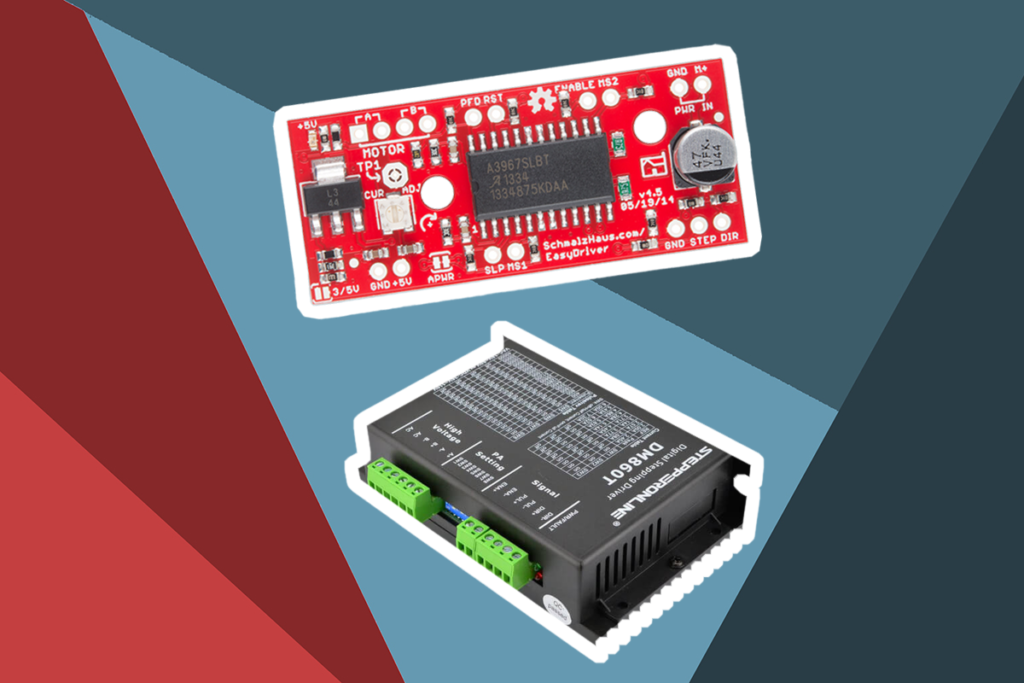

Plenty of things could potentially go wrong if you have accidentally imputed the wrong settings. Check out guides online on which setting works best with the filament you use, whether it’s metal or plastic. After all, all 3D printers are different, so what may work for one may not work for you.

Don’t get frustrated if your design didn’t turn out the way you hoped. As mentioned earlier, 3D Printing is a process of trial and error. You may feel like you are making many mistakes at first, but you will eventually get the hang of it. Part of the result is the experience you get, after all.

Make sure that your design features optimized shapes

The overall structure of your piece isn’t going to work if your design is bad. It is often recommended to use 3D Apps that can optimize your structures for you, or even searching for previously printed designs online and building up your own design from there. There’s no shame in that, as people often share free 3D Print plans for others to use. After getting the design, you are free to change as many fixtures as you want.

There are also applications that review the structure of your design. They can render 3D files to check if your model is either too thin or too thick. It’s a great way to check if your design will work once you print it.

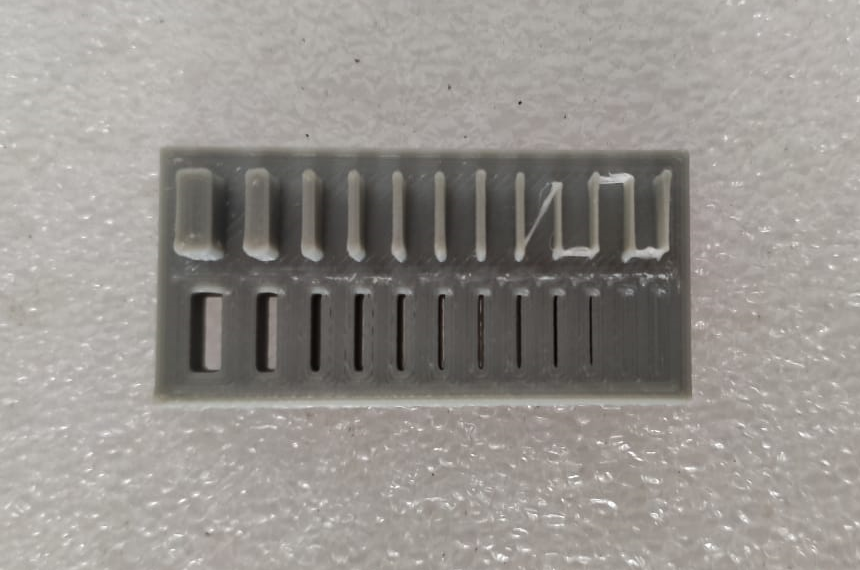

You can set a smaller scale of your model. There are plenty of scaling calculators out there for you to use. If you want to know if your structure is good, simply rescale it to a smaller size and print that one out first. This way, you’ll be able to see any hiccups and mistakes without wasting that many filaments.

In order to know which filament to use, you need to recheck your design. If it’s stable enough, you may get away with using softer prints. You can maybe even get away with having minimum wall thickness throughout the entire 3D Printing if you use a stronger filament.

Do the minimum wall thickness matter in 3D Printing?

Do the minimum wall thickness matter in 3D Printing?Yes. Having walls that are too thin can result in your piece breaking.

Hopefully, you were able to learn more about 3D Printing. In case you didn’t notice, the art itself needs to be taken into a more holistic view. You can’t make “this” without making or having “that”. This may lead to having redo designs over and over again, as the learning curve can take a while to go over.

It’s important to remain patient with yourself as you reapproach the project, no matter how long it will take. It might seem an impossible task at first, but soon you’ll be able to create structurally sound designs without having to peak at the guidelines. Just make sure not to make those walls too thin, okay?