Direct drive printer offers better speed and higher accuracy with a single design upgrade – allowing motor to move the print head directly. Yet as simple as it sounds, the rest of the machine is a complicated mechanism that should be carefully looked at before purchase. And that’s where our team comes to save your time.

In order to find 5 best direct drive 3D printers, we had to sort through dozen devices that looked promising yet performed poorly. We’ve received the most impressive results with Sovol SV01 3D Printer. It doesn’t matter if you’re a beginner or a pro – we’ve got machine picks that will fit your needs. We’ve tested 3D printers using various aspects – accuracy, precision, speed and balanced our list based on their performance and prices. Read on to take a closer look!

More features: 11.8 x 10 in build plate, 0.1-0.4 mm layer thickness, 260°C max nozzle temperature, 110°C max print bed temperature, 1.75 mm filament diameter, TF-card and USB connection, 350W power

This direct drive 3D printer deserves all the praise and our Editor’s Choice nomination for excellent performance: it shows best printing quality at decent speed with its self-designed metal direct drive extruder. This is a truly universal machine; it can be used to build highly-detailed architectural models and miniatures as well as big prints as one piece. Bright 4.3-in touchscreen allows to follow the printing process from start to finish and change settings while the device is on pause. If you are working from home, this machine is a perfect match – it produces little to no noise and won’t wake you up at night.

Sovol SV01 Pro offers CR Touch sensors for automatic bed leveling that guarantees even printing. It is compatible with various bed materials and each memorized touching points can be formed to be re-used up to 100,000 times. Accuracy of the print is improved with stepper motors and dual Z-axis design – it features 0.001mm precision in vertical movement. Besides being a 3D printer, this machine can be used as laser engraver also. Device comes partially assembled and can be put together by one person in a few simple steps.

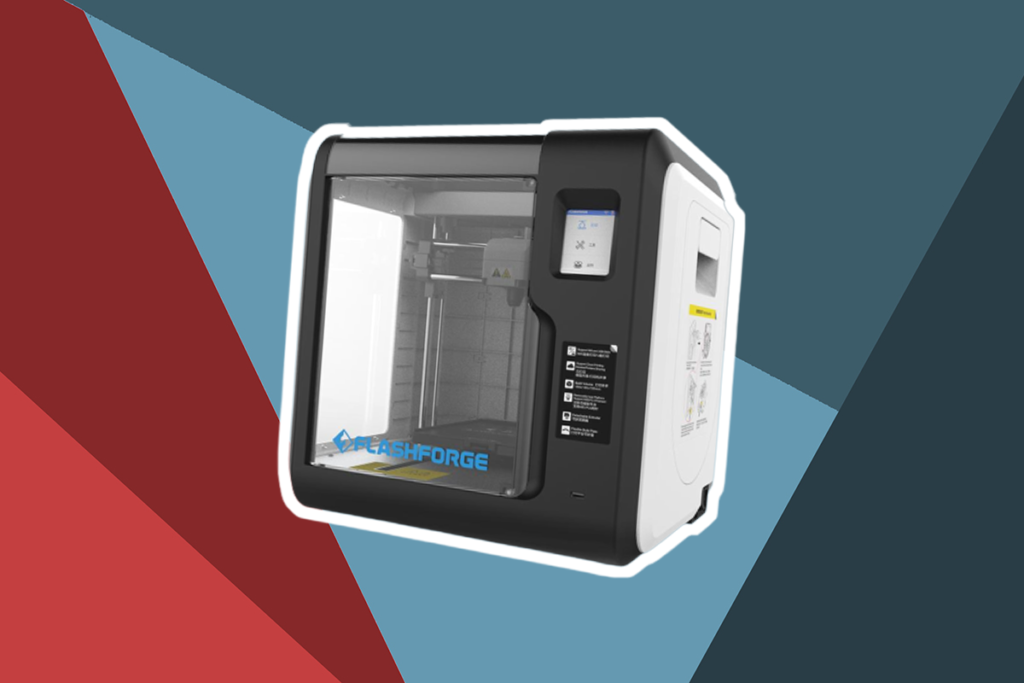

More features: double extruder, 0.4 mm nozzle diameter, 110°C max print bed temperature, 3.5 in touchscreen, 50 dB noise level, SD-card connectivity, 240°C max nozzle temperature

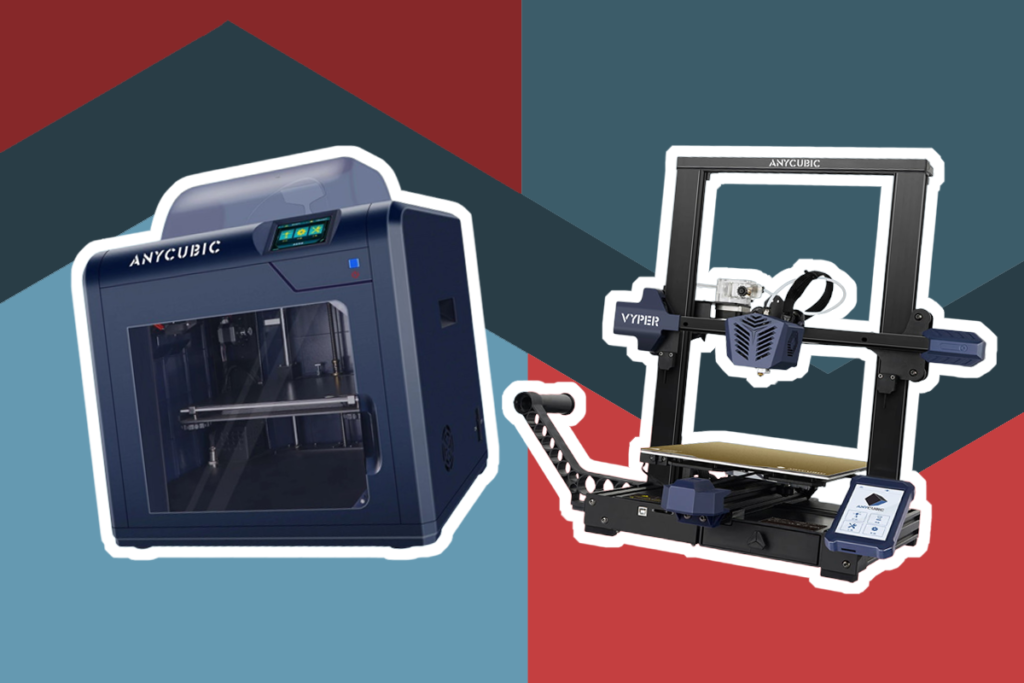

Enclosed direct drive 3D printer that comes with plethora of functions you won’t find in cheaper devices. We, of course, mean mirror and duplicated printing abilities. Flashforge Creator Pro 2 features independent direct drive dual extruders that allow you to create more projects in less time with two separately working nozzles. You can also use this option for 4 print modes, including dual filaments and color varying prints. This model also offers cleaner prints with the use of residue scrapping when printing heads switch for work.

Flashforge Creator Pro 2 is an upgrade of the first model that has improved many of the previous model flaws and added several features that weren’t available before. Model removal is now less tiresome due to work with flexible build plate. This machine is still compatible with classic PEI plate option if you need a specific filament to be used. To adjust the temperature now, you can remove the cover off the device without actually stopping the process. Flashforge Creator Pro 2, unlike its predecessor, now can fit more amount of filament for thicker and more detailed prints. The touchscreen also became a welcomed addition to the new machine design.

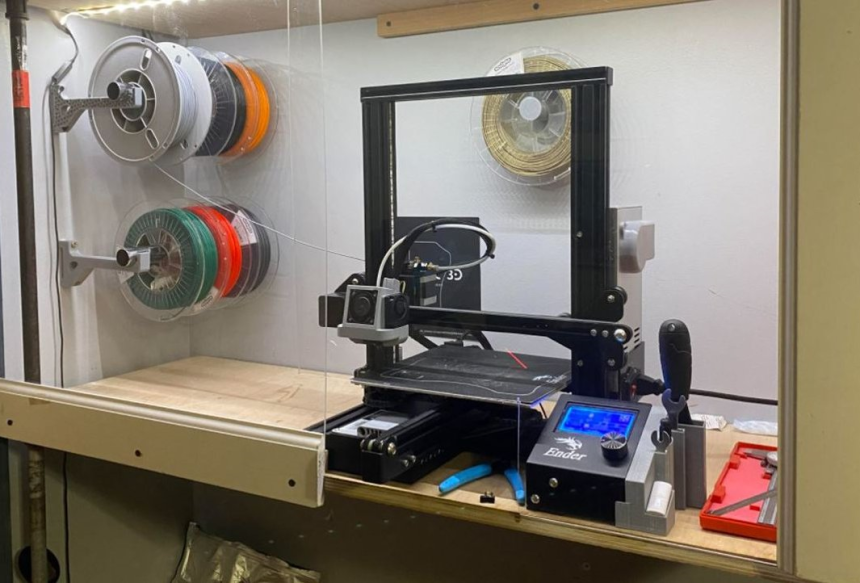

More features: 25-point automatic leveling, 7.95 in2 panel area, 110°C max print bed temperature, 0.4 mm nozzle diameter, 4.3-in LCD touchscreen, 260°C max nozzle temperature, 10-min assembly

This direct drive 3D printer is a perfect stepping stone for those who need to understand how to work with filaments, set up the machine and if the hobby can be something more. This device is rather cheap, yet it offers a great capacity for all the features needed for a simple 3D printing experience and offers all the benefits of direct drive printing. Anycubic Kobra is also extremely easy to assemble and the whole device weighs only 16.5 lbs, so you can move it around if the space is an issue.

Anycubic Kobra is one of the three machines in the Kobra line and while it is the cheapest, it looses nothing in useful features for beginner printers. For example, like our Editor’s Choice, it can work with extruders heated up to 500° F (260°C), thus expanding filament completability. Though it features smaller printing surface and looses some accuracy points, this device is considered a favorite amongst cosplay enthusiasts who prefer quick results for their hobby. We also find it impressive that for such a price, Anycubic Kobra offers a comparable touchscreen to the one in Sovol SV01 Pro.

More features: 16-point automatic bed leveling, 260°C max nozzle temperature, 50 dB noise level, 100°C max print bed temperature, double Z-axis, 4.3 in LCD touchscreen, automatic screen dimming, 6-step assembly, 0.05-0.35 mm layer thickness, 0.4 nozzle diameter, 350W power

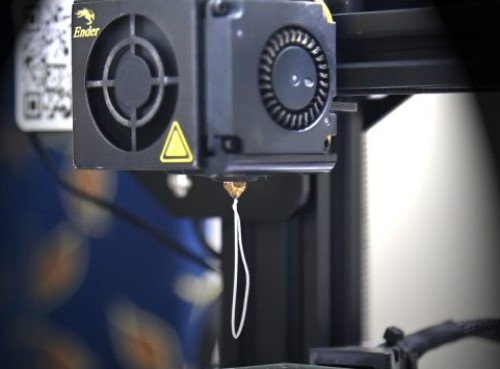

Creality Ender-3 S1 is one of the best direct drive 3D printers to use for highly-detailed projects. This device has impressive 0.1 mm printing precision with minimal layer thickness of 0.05 mm. It offers variability in filament choice and won’t disappoint even professional users, who like its capacity for upgrades. This machine has clear LCD touchscreen with all the settings and functions right under your hand for calibrations and checking on the printing process. Ender-3 S1 also has filament detector that will automatically stop the printing process if you run out of the product and will resume working once you’ve re-stocked, without losing any quality or dropping previous settings.

Creality Ender-3 S1 is a model compatible with many options on our list. It features the same lightweight design and simple assembly as Anycubic Kobra. They also both offer low-noise performance. Even though our Best Value choice has higher maximum printing speed, it lacks in accuracy, while Creality Ender-3 S1 has balanced quality/speed results. Filament control and direct drive performance is somewhat comparable with Sovol SV01 Pro, both printers offer high-precision process controlled at every step of the way.

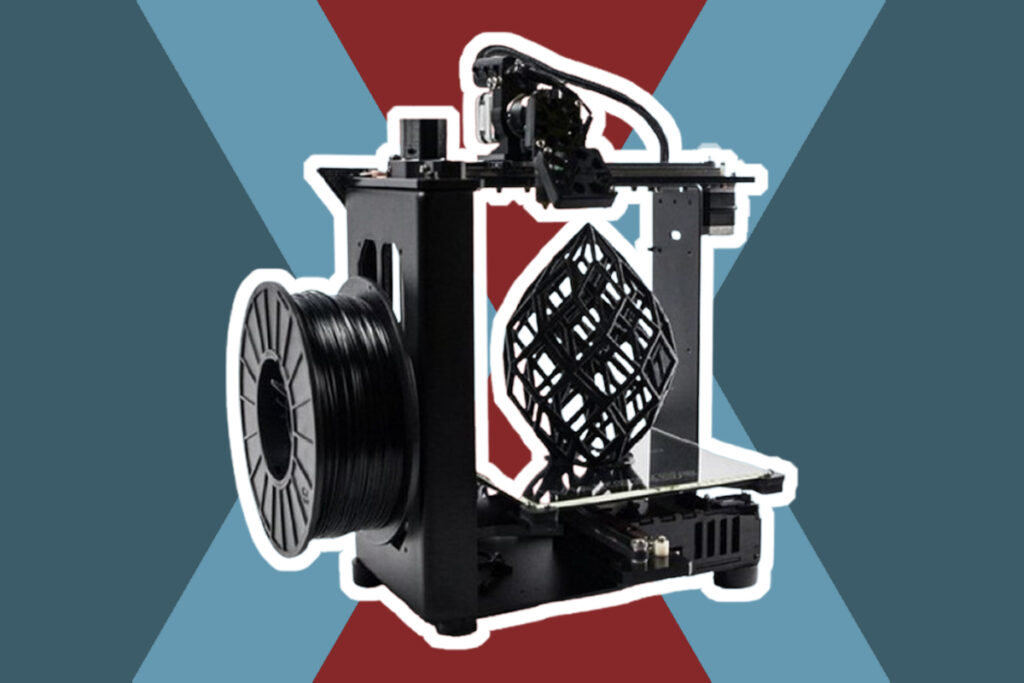

More features: 300°C max nozzle temperature, 0.05-0.35 mm layer thickness, 0.4 mm nozzle diameter, 120°C max print bed temperature, magnetic print bed, 120W power, power loss recovery, open-source hardware and firmware

Prusa i3 MK3S+ is one of the most impressive direct drive 3D printers with wide range of functions and even ability to work with re-printed details, making it the beat rep-rap 3D printer. This model offers impressive material range, widest on our list. This printer features parts and details made with high-quality materials. It can memorize printing settings and will resume the process even after a power loss. This model checks filament access to extruder with trigger system and will stop printing if you’ve run out of the material.

Like Creality Ender-3 S1 it offers high printing speed, even though we found that accuracy can be an issue at fastest setting. What Prusa i3 MK3S+ offers, unlike all the other printer models on our list, is a high-temperature nozzle and printing bed tolerance, working at 300°C and 120°C respectfully. What MK3S+ lacks, is a clear touchscreen that can be used to control the printing process, like you can do with Sovol SV01 Pro. Yet we must admit, that this machine is one of the most compact and lightweight options on our list. It looses nothing in the device’s quality while being even lighter than our Best Value option Anycubic Kobra.

Now that you’ve met our choices for the best direct drive 3D printer, it’s time to check which parameter we have considered important to make an informed decision in buying a long-lasting machine. In this section you’ll find tips on picking certain 3D printer parameters that fit your goals, advice on device’s maintenance depending on the type and the most frequently asked questions resolved by our professional team.

To purchase the right 3D printing machine, you need to understand main functions of the device and how each will change the printing experience.

3D printer is a rather complicated machine, its performance is formed by the quality of parts and even materials that are used for work. Fused-deposition modeling, or FDM printing technology, uses two extruder setups – Bowden and direct drive. We’ll concentrate on the latter as the more convenient option for most 3D printing enthusiasts.

Extruder placed directly on the printhead allows filament to flow through the hot end right away. This printing method has many benefits, mainly, it will require less maintenance and can work on cheaper parts. Direct drive 3D printer works on weaker motor due to having to produce less power for the extruder placed close to nozzle. Direct drive extrusion also works with wide range of filaments, getting better results with abrasive and flexible materials.

On the downside, maintenance of such machines can be troublesome since extruder placement leaves less space to access certain parts. If you’re not thorough with your printer settings, you might lose printing accuracy due to vibrations of the printhead. You might need to check each and every filament and how solid is your printing result.

Build volume of a 3D printer is the maximum result of your device’s capacity to build a single creation. Depending on your needs, you can opt for cheaper and thus smaller 3D printers, that feature less build volume but don’t loose in accuracy. In our selection you’ll find models with various working dimensions, biggest being Sovol SV01 Pro with building volume of 11 x 9.4 x 11.8 inches. Most direct drive 3D printers won’t exceed 8 x 8 x 8 inches of printing space, which is more than enough for most working needs.

If you don’t need massive devices for your projects, we advise you to check this list of the best 3D printers for miniatures.

3D printer’s speed calculations won’t mean much if you loose in accuracy, such parameters are always going hand in hand. When you see printing speed feature, you should always understand that in complicated prints with high count of details, you won’t be using max printing speed if you need better results. Direct drive 3D printers usually offer around 150 mm/sec printing speed, which is superior to most common devices with other printing functions.

Filament is a materials that is used to build your project, there are around 20 types that are commonly used with direct drive 3D printers. You can meet filaments that are basic, fit for beginner-grade projects and more complex, professional printing, that require thorough settings.

Basic direct drive 3D printers use PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene) filaments an often come with a sample kit of those to test your printer’s work right out of the box.

PLA is biodegradable and now is considered the most popular type for most printing projects. Where it won’t work, ABS comes in as a more solid option.

You can also use PETG (polyethylene terephthalate glycol-modified) filament for projects that require extra durability. It is mostly popular for glass-like effect and ability to withstand variety of paints to cover it. Prusa i3 MK3S+ is an exemplary 3D printer that works with a great variety of filaments for beginner and pro-grade type of work.

To succeed in 3D printing business, you’ll need device that is capable of creating even textures, clear details and won’t warp the base. Direct drive 3D printers are most known for their ability to make precise prints since filament has less travelling to do and is fed directly though the nozzle.

Most direct drive 3D printers offer around 0.1 mm printing accuracy. Through our testing, we’ve got the most accurate and impressive results with Creality Ender-3 S1, that is a great option for users who need pro-grade results at a decent price.

If you prefer accuracy over all other qualities in a 3D printer, you should check this list of the best 3D printers for architects.

Extruder is one of the main parts of a high-quality 3D printers. In direct drive printers, extruder feeds the filament directly through the nozzle and cut out many steps that could go in between. Most 3D printing machines feature single extruder that works with one material type at once.

In our list you’ll find Flashforge Creator Pro 2 that features dual extruders, which means it can basically perform two different tasks at once. it is a convenient feature but it won’t be easy to follow for beginners. Double extruder not only offers parallel working on the same model, but can also create projects made of separate filament types and colors.

Filament is pushed through the nozzle and its diameter determines how detailed your work can be. Standard nozzle size is 0.4 mm, but there are direct drive 3D printers that offer smaller options. You can always switch the nozzle to the size that fits your purpose; larger nozzle allows the printer to work quicker at the expense of small details (which are not necessarily needed in bigger projects). Check out this list of the best 3D nozzles to find the perfect match.

Molding technology determines how the object will be made in a 3D printer. There are 7 common types of printing process, but most direct drive devices use FDM, or fused deposition modeling. It is mostly used for small-scale objects, detailed prints and prototyping. In FDM printing the object is built layer by layer with hot plastic being deposed through the nozzle.

There are also two more popular direct drive 3D printing technologies: SLA, or stereolithography and SLS, or selective laser sintering. Both use laser to create objects, yet SLS uses sintering powder.

Direct drive 3D printers are really tricky to maintain in good condition. You need to follow a certain routine before set up and after finishing each projects if you want to avoid greasing up the parts and breaking motor. Here are important tips on keeping your machine well-running and serving you for a long time.

While the printer is working, certain temperature should be maintained throughout the whole process. It would differ for each filament type and needs to be thoroughly monitored in order to receive high-quality project and avoid ruining the nozzle and motor. Some printers like Sovol SV01 Pro and Anycubic Kobra can hold nozzle temperature at the maximum point of 260°C allowing wider choice of filaments to work with.

It is recommended to look at the temperature changing during the test print and track the whole process in order to avoid any unnecessary corrections in the future. Change the settings in the middle of the printing if needed.

Dirt and debris in the filament can cost you the whole day of work and drastically slow down the printing process. Not to mention the loss in printing quality and details is unavoidable in that case. Wipe the filament with a clean cloth before each use and use a vacuum cleaner if needed. We also recommend storing the filament in a separate container.

It is easier to keep filament clean in closed 3D printer, like Flashforge Creator Pro 2 – it doesn’t allow dust and unnecessary components to get through the casing.

Before the start of each project, make sure the print bed settings are all followed and the leveling is done correctly. Regular cleaning will help you keep high-quality prints and avoid warping. Depending on the material your print is made of, you’ll need different media to keep the surface clean. Glass print beds need scraping of the debris and wiped down, PEI or polyetherimide sheets need to be wiped down with the use of IPA and adhesive tapes will require gentle and careful scraping that won’t damage the surface.

These parts are tricky to get to clean and need to be taken care of right after you’re finished with the projects or just going to pause. A soft bristled brush is enough to regularly maintain print head and nozzle in good condition, you can also use cloth to remove any debris left.

Direct drive 3D printers are a popular type of machines and updates appear quiet regularly online. They can be from approved developers or just done by enthusiasts. Some manufacturers keep an open-source code so every user could upgrade their machine as needed. Prusa i3 MK3S+ is one if such devices and it is responds well to every new set up made for it.

The quality of your print is affected by many parameters and keeping a close look at the main axes is rather important as you might know. Nor only you should avoid leaving them unattended, but regular cleaning will make your prints to be built much quicker. Always check how belts and bearings are placed and how far are they worn, so no sudden stops will appear in the printing process.

We hope that these tips have made you experience as a 3D printing enthusiast much better and you will follow them to make the most of your device!

Extruder heats the filament and pushes it through the nozzle. Nozzle temperature may vary, but most of them can hold up to 200-230°C heating, thus it melts down the filament and pushes it through onto the build platform. The filament cools down and thus forms the desired base, while the printer build the final project layer by layer.

Bowden setup places extruder on printer’s frame and doesn’t weigh down the carriage. Direct drive setup places extruder above the nozzle.

We’ve explained already what direct drive printers can do, so let’s focus on pros and cons for the Bowden. First and foremost – since the extruder is placed farther from the printhead, it requires more powerful motor. This makes your device rather expensive in maintenance and re-setting. Bowden extrusion type limits your filament choice, flexible materials can damage the tubes they travel through. We also find it rather inconvenient that Bowden extrusion takes more time to respond to your set ups and changes you’ve made throughout the printing process.

On the bright side, Bowden method is mostly used to build grand projects that can’t be build with the use of direct drive extrusion. We also find it beneficial how it allows to have a quiet printing process with less motor vibrations and cleaner cuts.

To improve print quality, you might needs to change several things about the way you handle the printing process. First – test printing is not just to check if your printer works fine, it also allows you to see the first flaws in the set up you’ve made, how nozzle temperature can change and which filament can be used.

All of those factors are seen on the first print and they can help you set up the further working process. Second – don’t go cheap on filament or you might have to spend twice as much money once it botches the whole project. Third – change the nozzle if you want more details. Enjoy the tiniest projects at full scale of you printer’s capacity for precision.

Direct drive 3D printers are popular for a reason. Actually, for several reasons that we will list here for you.

They offer wider choice of printing materials. Your projects can be as different and creative as you desire, there’s no need to hold yourself back. Extruder can keep higher temperatures for tougher materials and let you support even the most daring projects.

Filament retraction. Extruder is placed directly above the printhead and can help hold the excessive filament in place while the printhead is moving to another part of the project without leaving a trace.

Simple motor. There’s no need for expensive parts and powerful motor to support the working process. The filament is pushed with the same power as in regular printers yet the motor doesn’t need to put more effort into it.

Better speed and precision. Direct extruder allows the filament to take less time to travel through the nozzle and printing takes less time while staying accurate with the hot filament forming the right shape right away.

With all that information we’d like to sum up what’s been described in this article at full detail. Direct drive 3D printers have lots of benefits and are a great option for both beginners and pros.

At the top of our list stands Sovol SV01 Pro – device that comes at decent price and offers excellent performance with high precision and speed. This machine is made by a reliable manufacturer and can be a loyal companion f or many years of successful work.

Next comes an enclosed option for pro-grade 3D printing – Flashforge Creator Pro 2. This device is perfect for miniatures and detailed architectural builds. It offers great choice of filaments to work with and features double direct drive extruder to work on two projects at once. Though it costs a decent sum, we know it will be money well spent.

And last but not least, one of the best direct drive 3D printers that balances price and quality well enough – Anycubic Kobra. It’s a well-known machine with simple set-up that can be a perfect first buy to get sucked in the world of 3D printing.

We hope this article has helped you find the right machine for your needs and you will succeed whether you’ll buy for hobby or work!