In the world of 3D printers, nothing works quite as TPU for a filament. Did you know that not every 3D printer can use this versatile material? When preparing our list of the best TPU 3D printers, we first looked at the style of technology that they utilize since this determines what they can make. Next, we looked at the build volume and print speed, as these also directly influence the types of projects that you can design and print with the machine. Finally, we looked into the different materials aside from TPU that can be used as filament and the software needed to operate the printer correctly.

This open-frame 3D printer utilizes FDM technology to create its projects. It can be utilized with a variety of materials aside from TPU, which include ABS, HIPS, Wood, and PLA. This model has a print speed of 20-100mm/s, giving it a large range to choose from for printing projects. It also has a very large build volume of 400 x 400 x 450 mm.

This device is excellent for anyone that is looking to print larger objects. It has a large build space that is perfect for bigger projects. It can utilize a variety of materials and print speeds, making for a versatile, do-it-all type of 3D printer.

This enclosed frame 3D printer uses FDM technology to create its projects. An enclosed printer has a larger volume of 270 x 210 x 190 mm. It also features a wide speed range of 20-150mm/s. This model can be used with lots of different software options, including Cura, Simplify3D, Repetier-HOST. It can also be used with a wide array of materials aside from TPU.

This machine is a great option for anyone that is looking for the safety and ease of an enclosed 3D printer that has an exceptionally large build volume. This machine is also quite user-friendly, as it can be used with a variety of printing software.

This value-based 3D printer uses FDM technology and an open frame for its projects. Though it has an open frame, this model has a smaller build volume of 220 x 220 x 250 inches. This model can be used for a lot of materials and has a wide speed range.

This machine is a great option for anyone that is looking for a great 3D printer that doesn’t cost too much. This model is designed to provide a great value that can handle lots of projects without a ton of bells and whistles. These design features also help to make this a good machine for beginners or amateur printers.

This enclosed style FDM printer has a build volume of 200 x 148 x 150 mm. It can be used with a variety of materials and uses FlashPrint software. This model has dual extruders, which can help to increase the output as it can print two items at the same time. It can also be used to print with two different filaments at a time to make extremely versatile projects.

This machine is a good option if you are looking to print more than one object at a time. It has a set of dual extruders, which allow to print two items at once or print a project with two different types of filaments, making for more complete projects. Of course, this will only work if you are printing smaller objects, as the enclosed design does limit the build volume.

This enclosed style printer uses FDM technology to create its projects. Since it is enclosed, this printer has a smaller print volume of 270 x 200 x 200 mm. It can be used with a wide array of materials and utilizes QIDI software. This model is very easy to use, making it perfect for beginners.

While this printer is on the smaller side, it is a great 3D printer for a beginner. This model is ready to use right out of the box, and the QIDI software is well-known for its user-friendly features. The smaller size of this unit won’t take up a lot of room in a home either, making it ideal for anyone that is only going to print on occasion or for recreational purposes.

This self-leveling FDM printer is an open-frame model. This unit has a build volume of 245 x 245 x 260 mm. It also has a very large print speed that can go all the way up to 180mm/s. This machine can also be used with a variety of materials aside from TPU and utilizes Cura software.

This model is another great choice if you are worried about the setup for your new 3D printer. It comes almost ready to work right out of the box, and the instructions for utilizing it and changing the filament are very easy to follow and understand. The auto-leveling feature is another big plus for anyone that is looking for an easy setup device.

This FDM 3D printer is an open-frame model. It has a large build volume and a wide speed range. It can be used with a wide array of materials aside from TPU. It is very easy to level and is also ready to use with very little setup.

If you are someone that wants to be able to print a wide array of projects that require different speeds, then this is an excellent model. This unit has a large range of print speeds that you can select from, making it ideal for both large and small projects. It is also ready to use right out of the box, which is another big plus.

In this section, we will go through everything that you need to know to find the best TPU 3D printer for your needs. We have also taken the time to answer several frequently asked questions, so be sure to read through those as well if you need any further information.

All types of 3D printers are versatile machines that can make amazing creations come to life. TPU Trusted Source Thermoplastic polyurethane (TPU)-based polymer nanocomposites - ScienceDirect Thermoplastic polyurethanes (TPU) are a commercially important class of thermoplastic elastomers, which have an inherent nanostructured morphology. This chapter introduces thermoplastic polyurethanes before summarizing the benefits of introducing various types of nanofillers using various processing methods and highlighting the engendered properties and performance. A detailed discussion of the influence of nanofillers on TPU morphology is provided, as well as a section on biomedical applications and nanofiller toxicity. www.sciencedirect.com , or thermoplastic polyurethane Trusted Source What is TPU | Thermoplastic Polyurethane Materials | HEXPOL TPE Thermoplastic Polyurethane compounds (TPU or TPE-U) are a class of Thermoplastic Elastomers (TPE). www.hexpol.com , is one of the most impressive Trusted Source Thermoplastic polyurethane composites reinforced with renewable and sustainable fillers – a review: Polymer-Plastics Technology and Materials: Vol 59, No 16 Thermoplastic polyurethane (TPU) reinforced with natural or renewable fillers gained significant attention in the scientific community and industries. The properties of TPU can be tailored using different reinforcements or blends to enhance its performance and elevate the potential applications of the composite. www.tandfonline.com filaments on the market. As such, TPU 3D printers offer up some pretty significant advantages over their competitors. These include:

Aside from using TPU, these printers can operate at a wide range of temperatures. This makes them perfect for a variety of different materials. If you decide to purchase a TPU 3D printer, there is no limit to what you can use or what you can make, which makes them a perfect purchase for anyone looking to really expand their printing prowess.

As you can imagine, there are plenty of things to look out for when you are in the market for a TPU 3D printer. In this section, we will explore the ins and outs that you need to keep in mind when looking for a TPU compatible 3D printer for your use.

In the world of 3D printing, there are several different printing technologies to choose from. When it comes to a machine that is capable of utilizing TPU, however, it all comes down to FDM, which you can see in the ANYCUBIC Chiron. This technology, which is also known as Fused Deposition Modeling, is one of the more common types of printing technology on the market today. This makes sense, as it is a practical method for printing designs.

In FDM, a thermoplastic filament is heated until its melting point. From there, it is forced through an extruder or tube to create a series of layers.

These layers will add up to the item that is being printed once the process is complete. Since the layers for TPU are usually quite warm, the layering needs to be relatively small, which makes for more detailed projects.

The build volume is the amount of space that you are going to be able to use to make a creation on your 3D printer. The larger the build volume, the larger the item that you can build with your machine. Each machine is going to have a different amount of height, width, and depth, which means that you need to plan carefully before you make your final decision.

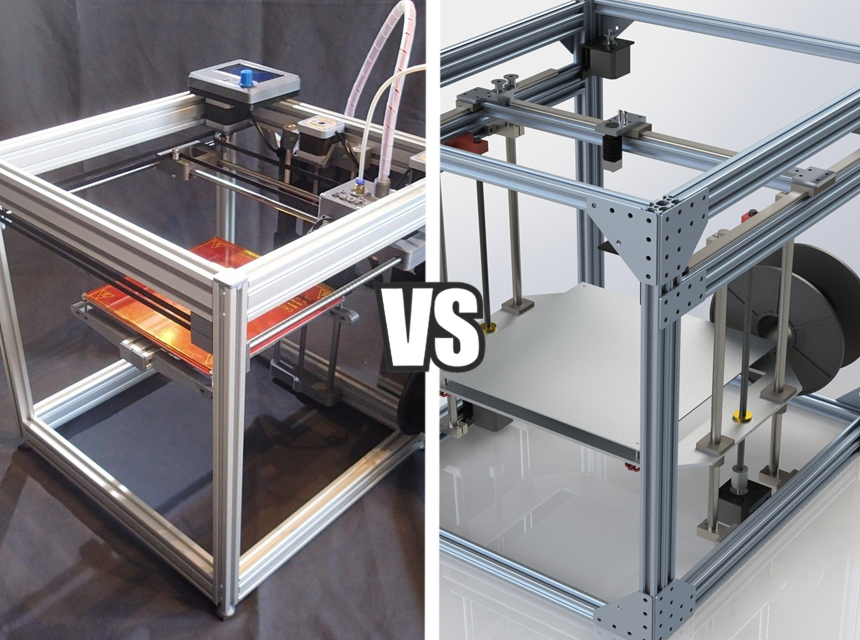

There are two different types of 3D printers that you can purchase. These two choices are an open model or an enclosed model. Obviously, an open model like the ANYCUBIC Chiron is going to have a larger build volume than an enclosed one like the FlashForge 3D Printer Creator Pro2.

Either printer will work well with TPU and other materials, but open models can make much larger creations.

The print resolution, or layer resolution, is how tall each of the different layers is going to be in your printed piece. It is important to remember that the smaller the layers that you can print, the more precise the machine will be. This will, in turn, have a huge impact on how your creation will end up looking. Rough drafts are usually best printed with larger layers so that you can get a rough idea of how it will look. This will also allow you to print more quickly. Finished products, however, should be printed in smaller layers, as this will give a much better amount of detail.

Print resolutions are usually communicated in mm or in microns. These two terms are completely interchangeable, as 100 microns is equal to 0.1 mm.

If you are looking to print things with as much precision as possible, then the ANYCUBIC Vyper is an excellent option. This machine only creates layers of 0.1 mm in thickness, making it an excellent option. If you want a bit of variety in your layering, then the ANYCUBIC 4Max Pro 2.0 is a good choice. This model’s layers can vary between 0.05 mm and 0.3 mm. This will allow you to make both rough and final drafts with as much precision as you desire.

There are lots of different materials that you can choose from when it comes to 3D printing. Obviously, you can print TPU with each of these printers, but some of the more popular materials are as follows:

Another important factor to keep in mind when you are looking for a 3D printer is print speed. This is the rate of material that the printer can put out over a given amount of time. Generally, this is usually measured in millimeters per second. Obviously, the higher the number, the faster the printer is going to go for you.

Depending on the type of work that you are trying to print, you might need to get a slower or faster model.

Generally speaking, the higher the print resolution, the slower the speed of the printer, and vice versa. If you are ok with printing projects that don’t have to require small details, then you can get a pretty fast printer. On the other hand, models that can provide the most detail for your projects are also going to be on the slower side. You could, of course, go for something like the FlashForge 3D Printer Creator Pro2, which has a wide range of speeds from 20 mm/s to 100 mm/s to choose from. This wider range will allow you to fine-tune your speed to meet your needs for each project.

When choosing a 3D printer, it is usually best to stick with one that utilizes a printing software that you are familiar with. After all, the last thing that you want to do is have to learn a whole new system once you get your printer set up. There are lots of different software options in the world of 3D printing, however, so it might be a good idea to look for a printer that can be used with a variety. Of the models on our list, the ANYCUBIC 4Max Pro 2.0 is going to be your best bet, as it can be used with a wide array of software options.

Finding the right TPU 3D printer can be a bit of a challenge. You need to consider what other materials can be used with it, the types of printers available, and the features you desire.

Out of all the different models that we looked into, the ANYCUBIC Chiron is by far our favorite. This model has an enormous build volume and is very easy to use. It also can work with a variety of materials, making it an exceptional value.

The ANYCUBIC 4Max Pro 2.0 is an awesome enclosed 3D printer. This model has a large build volume for an enclosed model and is also extremely precise in its printing.

If you are someone that thinks the best TPU 3D printer is the one that is the easiest on your wallet, then the ANYCUBIC Mega SE is a great option. This model provides an easy-to-use interface and builds volume for your money.