One of the main reasons that have greatly contributed to 3D printing industry growth is the availability of open-source printers. Printers developed as open-source allow users to contribute to printer-related updates as the industry evolves to meet consumer needs.

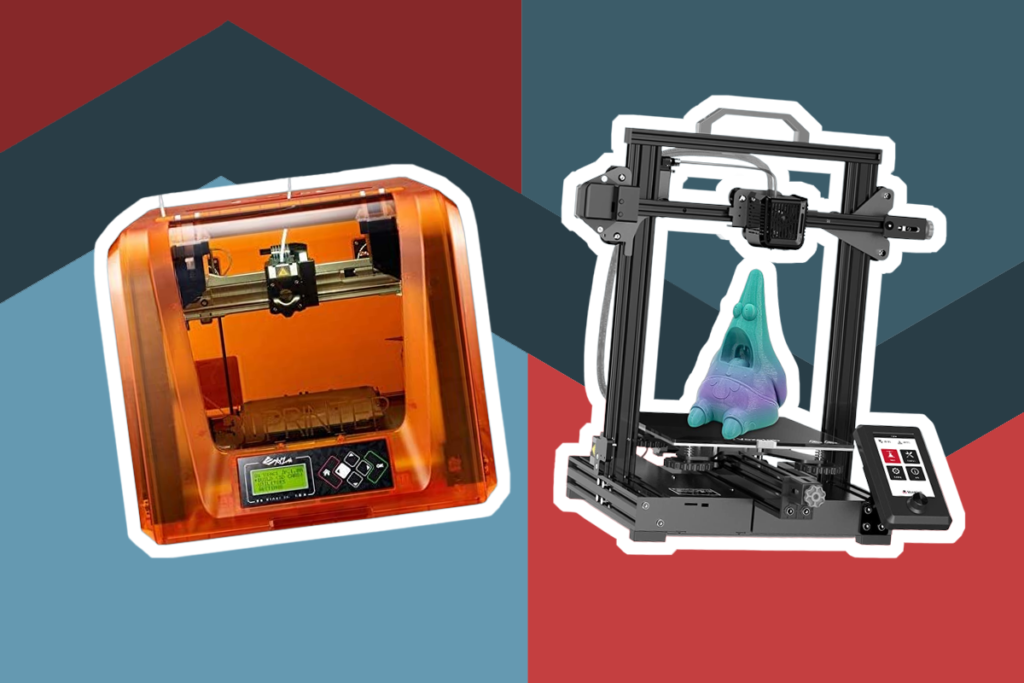

There are many options for users; however, it is difficult to choose one. We set out to help you choose the best open-source 3D printer for your needs. Some printers provide huge printing space and plenty of compatible materials. Then some are easy to set up and operate. Manufacturers have also created inexpensive machines for those on a budget. With this list at hand, you’ll get a reliable option, no matter which one you choose.

Creality CR-10 V3 is our Editor’s Choice as it comes at a very attractive price compared to most other open-source options out there, and the source files are available in great amount. It comes with an FDM technology with a high-performance Titan direct extruder for excellent results. The machine is compatible with ABS, PLA, PETG, and TPU filaments of Ø1.75 mm. The multifunctional 3D printer allows the printing of rigid and semi-rigid filaments for 200 hours of uninterrupted work.

It’s perfect for printing models, objects for medical use, parts for robots, everyday products, personalized accessories, and more. The only difference between the Creality CR-10 V2 and the CR-10 V3 is the extruder. The earlier version has an aluminum Bowden and the newer is a direct Titan type. It looks like one of the types found in the best direct drive 3D printers. Otherwise, they are the same: bearings, stabilizer bars, profiles, hotbed, hotend.

But what were the improvements of V3 with respect to V2? One and only one: the change from Bowden extruder to direct. The rest of the printer was the same. EVERYTHING. This improvement was worth it, but, the price increase is quite higher, so it is even better for you to buy a V2 and change the extruder yourself.

The Prusa i3 mk3S+ 3D printer is to date the best-upgraded printer with good value for money on the market when it comes to FDM 3D printers for individuals. Also, year after year, it is voted best FDM 3D printer in its category by the specialized magazines Make and Forbes, thanks to its reliability, robustness, and features.

Considered one of the best RepRap 3D printers, the Prusa i3 MK3S+ 3D printer is intended for individuals, enthusiasts, and students. Also, this is a good open-source 3D machine. PRUSA brings permanent improvements to its 3D machines which can also be adapted to old 3D printers. This 3D printer truly embodies the RepRap philosophy (rapid reproduction) of the project from which it originated. You can thus add the multi-material plugin to your PRUSA i3 MK3S allowing you to print up to 5 materials simultaneously! All without having to buy the new version of the printer but simply the plugin to install on your machine.

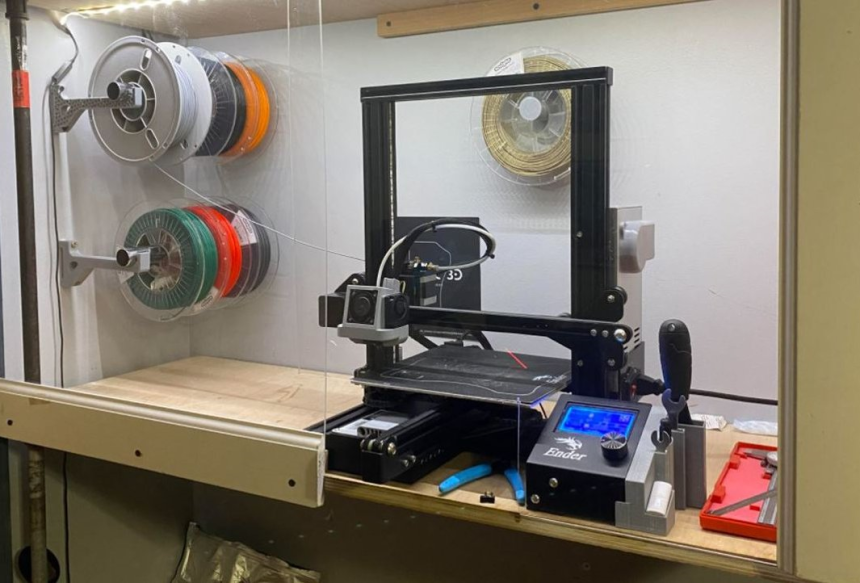

The Creality 3D company is standing out in the field of cheap but valuable 3D printers. The Creality Ender 3 is a 3D printer for those looking for an affordable 3D printer on a market where there are rivals as strong as the Anet A6 or the Anycubic I3 MEGA.

It is a 3D printer similar in design to the brand’s Creality CR-10, which is considered the best Creality 3D printer and its older cousin. However, this Creality Ender 3 is smaller and more compact: the measurements of the machine are 440 mm x 410 mm x 465 mm, and its weight is around 18.5 pounds.

The Creality 3D Ender 3 is a 3D printer halfway between DIY and pre-assembled. It comes with some parts already assembled, but others have to be assembled by the user. In total there are about 12 steps that take about 2 hours. This 3D printer has a print volume of 220mm x 220mm x 250mm, smaller than the Creality CR-10 but similar to other 3D printers in its range, such as the Anet A8.

This 3D printer is for those who are looking for easy-to-use machines that need little to no tinkering. Many people base their selection criteria on how easy the device is to operate. And, LulzBot Mini goes a step further to ensure that users find it very easy to work with the 3D printer. Only after 15 minutes of unpacking, the 3D printer can be used for the first print. All you need to do is connect and start printing high-quality objects.

As its name suggests, the 3D printer offers a small printing space. It has a print volume of 160x160x180 mm. Several other advanced features make the device competitive and desirable. It has a self-balancing bed and a self-cleaning nozzle. The device is also compatible with a wider selection of filament types. It also supports third-party filaments along with a heated bed. The all-metal hot-end nozzle allows users to create models using industrial-grade materials.

However, noise levels are an issue when working with this little printer. This can be handled by engine settings. The main drawback of the 3D printer is that you need to connect a computer when it is working. Also, there is no interface on the machine. Therefore, a computer is needed all the time.

The vision of the creators of the Voron is to create a 3D printer that does not need constant adjustments or updates. This means that you will have a printer built to last. The printer has FDM technology. It supports materials such as PLA, ABS, PETG, ASA, and more.

The Voron 2.4 is becoming for the CoreXY 3D printers what the Mendel was for the Cartesians. The Voron is for those who want the ultimate 3D printing machine, and have a DIY and tinkering mood. So you have to keep in mind that you will have to assemble the 3D printer from scratch. You should consider this printer as a project. Due to this process, you will spend more resources on this machine than most others on this list.

One of the problems with XY printers is that the base moves on the Z-axis: the base is not fixed and is more prone to vibration. But that’s not a problem for this model. The Voron moves the head in all three axes. And also the Z-axis does not go with spindles, which adds precision and speed.

The construction and design in this printer allow it to be closed, creating a hot chamber and also confinement for toxic fumes. If you mount a HEPA filter, you will reduce this potential danger almost to 0.

In 2014, the company Aleph Objetcs presented its new 3D printer Lulzbot Mini to the public at the Inside 3D Printing Conference. The 3D printer is the fourth prototype of the LulzBot devices and is listed under the name ” Daffodil ” (Eng. Narcissus). The 3D printer is encased in a robust powder-coated aluminum frame. As for printing materials, it can process PLA, ABS, Tritan, T-Glase, Nylon, Polycarbonate, and other exotic materials such as wood, stone, and bronze. The metal frame of the printer consists of a new type of metal that is designed to withstand temperatures of up to 300 degrees Celsius (554°F).

This 3D printer is among the models by the manufacturer with the largest build volumes, as well as the TAZ Pro and TAZ 6. So it’s a solid option for those looking for a large open-source 3D printer that is still easy to use and reliable. The 3D printer’s heating bed has an automatic level control and a new nozzle cleaning process. The two functions were developed together with Sparkfun Electronics and are intended to offer users an intuitive printing experience.

The Monoprice Select Mini V2 is a 3D printer with small dimensions and a low price. It arrives whole and assembled. Also, it is accompanied by a few accessories. The block and its power cable are in two separate boxes, no doubt for reasons of the internal organization of the packaging. There’s a squeegee to unhook the creations from the tray, a micro-SD card (in its protective box), a USB cable, a small screwdriver, and finally the printer manual.

The name suits the printer since the Monoprice Select Mini has a fairly small size. It is thus easily placed on his desk, without having to devote too much space to it. With an open frame, the printer turns out to be quite aesthetic, whether in its black and white version or its exclusively black version. The different materials used, raw metal, aluminum, LEDs, add to this elegant design, which makes this printer a beautiful object.

Open Source technology has contributed to the popularity of 3D printers. These devices are open, in terms of compatible materials or Slicer software used. So, you can test, choose and use the technical solutions you want! In this buying guide, we’ll tell you what these types of printers are, how they differ from models that have a closed source, and what you should watch out for while choosing.

Open-source 3D printers are models that let you print from any type of material from almost any supplier as long as the resin is UV curable at 385 to 405 nanometers. Open source technology allows for co-creation between manufacturers and users. In the open-source world of printing, there are users in the community who seek to build parts for even new 3D printers. These parts will be acceptable by any printer, in as much as they are open source.

In the open-source 3D printing world, you’ll have access to various printer firmware, modeling software, slicer programs, hardware, as well as 3D printable files.

3D printing was not very popular from the beginning but it has now been gaining a lot of recognition over the last few years thanks to the availability of open-source printers. Printers developed as open-source devices allow users to contribute to printer updates as the industry evolves to meet consumer needs in today’s space.

With big names aiming to seize the opportunities entangled with the open-source ecosystem, one can easily find the best open-source 3D printer with so many options available.

Manufacturers are now working to create impressive 3D printers that use open-source technology to help users get the most out of it.

With fully open-source printers, manufacturers ensure the continuous evolution of their printers, both on the hardware side and the software side. This is why the printer will notify you of an available firmware update. Updating the firmware of the 3D machine is very intuitive and explained in the user manual.

With fully open-source 3D printers, all the materials, parts, software, and hardware used by the manufacturer are made available to users. That’s not the same with partially open-source models like the Creality Ender 3 and the Creality CR-10. These models are often discontinued on the market or replaced with models that are not open source. So, you’ll have a problem with partially open 3D printers, if anything happens to the material, parts, or software.

There are a lot of things to watch out for while buying a 3D printer. The most important among these are the:

In our review of the best 3D printers, we recommended devices with FDM technology such as Creality CR-10 V3 and the Voron 2.4 CoreXY. However, also popular are models with FFF technology such as the LulzBot TAZ Workhorse and the Monoprice Mini Delta v2. But let’s see what makes these technologies differ from each other.

Still known by the acronym SLA (StereoLithograph Apparatus), the process of this printer was patented in 1984 as a stereolithography machine. But photo-polymerization is the name given to the printing technique used to make 3-dimensional elements. Starting from a liquid material, the machine’s laser solidifies the resin obtained with each pass of the print head. The result obtained is of excellent quality, with a remarkably smooth surface of the objects.

Fused Deposition Modeling (FDM) printers use light but very strong materials for their printing. These are Polycarbonate, ABS, Nylon, PVA, PET, ULTEM, and ASA. Once the device has reached the right temperature (200°C), a filament of approximately 1.75 to 2.85 mm in diameter is superimposed on the reception plate via a nozzle that moves on 3 axes. The platform descends slowly until the complete impression of the object.

Also sometimes called FDM technology, the Fused Filament Fabrication (FFF) is understood as the manufacture of objects with meltable plastic. The objects are created using the layered construction process. The founder of the FFF process is S. Scott Crump, who first used the process in the late 1980s and commercialized it in the 1990s. The process resulted in the US company and today’s world market leader in 3D printing, Stratasys.

This model of 3D printer is one of the best because it works by using a plastic powder in cast iron, and a laser that carries out the solidification. In the opinion of the users, robustness is the first quality of this machine whose fields of application cover the sectors of design, medicine, automobile, or aerospace. For good reason, the objects created from a laser sintering 3D printer are robust, durable, and very resistant.

SDL or Selective Deposition Lamination is the 3D printing technique based on sheets of paper, plastic sheets, and laminated metals. Devices of this type laser cut the multiple layers of the object to be printed in different materials. The layers of sheets thus cut are then colored as needed and assembled on top of each other to obtain the desired object.

This printing technique in SDL is not the best since the finishes are quite rough. It is also the least expensive.

This volume is equivalent to the maximum size an object can have on a 3D printer model. Large volume devices are used for printing large parts or series of objects.

printing thickness. The volume refers to the minimum size of each layer of thread that forms the printed object. The finer the layers deposited are, the smoother the object and the better the print quality.

Although all 3D printer manufacturers want to put the best quality prints through their machines, there is always the choice of technologies and budget that make the difference in quality.

It is difficult to provide all the latest features while keeping the budget low. However, with 3D printer kits, you can save some money on the printer price and get a competitive enough 3D printer.

This criterion is not very decisive when you want to choose a basic 3D printer. The entry-level and mid-range models offer a print speed of around 150 to 200 mm/s. But for a professional choice, you have to look for speeds beyond 300 mm/s.

3D printers can be purchased as a ready-made printer or as a kit meant to be assembled from scratch such as the Voron 2.4 CoreXY. A finished device can be used immediately upon delivery, but 3D enthusiasts recommend buying kits. The reason: By assembling it, you get to know how the 3D printer works and the individual components better. This makes it easier to carry out extensions or repairs later. In addition, kits are a lot cheaper than already assembled 3D printers.

There are several thermoplastics, i.e. heat-deformable plastics, for use in 3D printers. They differ in melting point, adhesion and toughness. Therefore, you cannot use all materials on all devices. The standard is polylactide (PLA) and acrylonitrile butadiene styrene (ABS) in different colors.

These are compatible with almost all 3D printers of this type – and you do not have to rely on the device manufacturer’s brand. Read the manufacturer’s instructions to find out whether you can use other thermoplastics such as nylon or carbon-reinforced filament. SLA printers work with photopolymers, i.e. liquid synthetic resins. The appropriate grade is determined by the wavelength of light at which the resin hardens. As a rule, you have to use the device manufacturer’s brand.

The object to be printed must be created and saved in a 3D design program. The file is then processed by a software called “slicer” so the 3D printer can read it. Most manufacturers rely on free open-source solutions, which means the community can further develop open-source programs.

Proprietary software is also occasionally used. If you don’t work with multiple 3D printers at the same time, both solutions are ok, but the open-source software offers more control. Data can be transferred in several ways, a direct connection to the PC via USB cable is almost always possible.

There are differences in network connectivity, so some 3D printers have Wi-Fi and network cable connections. Other devices can also read the data from an SD card.

Of course, it is advisable not only to keep an eye on the price and the print quality but also on the quality of the device (and also the usable software).

The frame or the entire construction should be stable/robust, for example, as this is the only way to achieve very good print results. If the 3D printer wobbles, for example, due to vibrations, the printouts will quickly become inaccurate and therefore often unusable.

A not to be neglected point is the support and warranty. If you have problems with popular products, you can usually get help from other users. Manufacturer support, on the other hand, is not always reliable. In case you’re dealing with hardware issues, then you have to fall back on the warranty coverage.

Most 3D printers come with one to two years of warranty, which should be enough. But if you have a problem with parts of the machine, they are easily replaceable since we’re dealing with open-source machines.

There is a very wide price range for 3D printers. You can find cheap devices for less than 300 dollars, while printers for the semi-professional user can reach four digits. assessments differ depending on whether the device is intended for professional or personal use. But below is what the range roughly looks like.

There are inexpensive printers for young, creative users who would like to experiment with 3D printing. These do not always offer the best quality but allow you to familiarize yourself with the principle and achieve initial results. Most are SLA printers without a large scope of delivery.

You can get a solid 3D printer with a few templates and a large accessory base from 500 dollars. These devices use SLA or FDM technologies and come with the required plastic so you can start printing right away. In addition to finished printers, some kits offer the same performance at a lower price.

If you want a larger model or have particularly high demands, you should invest in a 3D printer in the four-figure range. So you get high-quality, durable printers that deliver the best results. Extra features such as WLAN connections and excellent customer service are also part of the package here.

We’ve reviewed some of the best models of 3D printers on the market that are open-sourced. Without mincing words, the Creality CR-10 V3 is our Editor’s Choice as it comes with an FDM technology with a high-performance Titan direct extruder for excellent results. The machine is also compatible with ABS, PLA, PETG, and TPU filaments, which is why we think it’s the overall best open-source 3D printer on the market.

Our Best Upgrade Pick is the Original Prusa i3 MK3S+. It comes with good value for money on the market when it comes to FDM 3D printers for individuals. Finally, our third best model is the Creality Ender 3, our Best Value Pick. The Creality Ender 3 is a 3D printer for those looking for an affordable 3D printer in a market where there are rivals as strong as the Anet A6 or the Anycubic I3 MEGA.