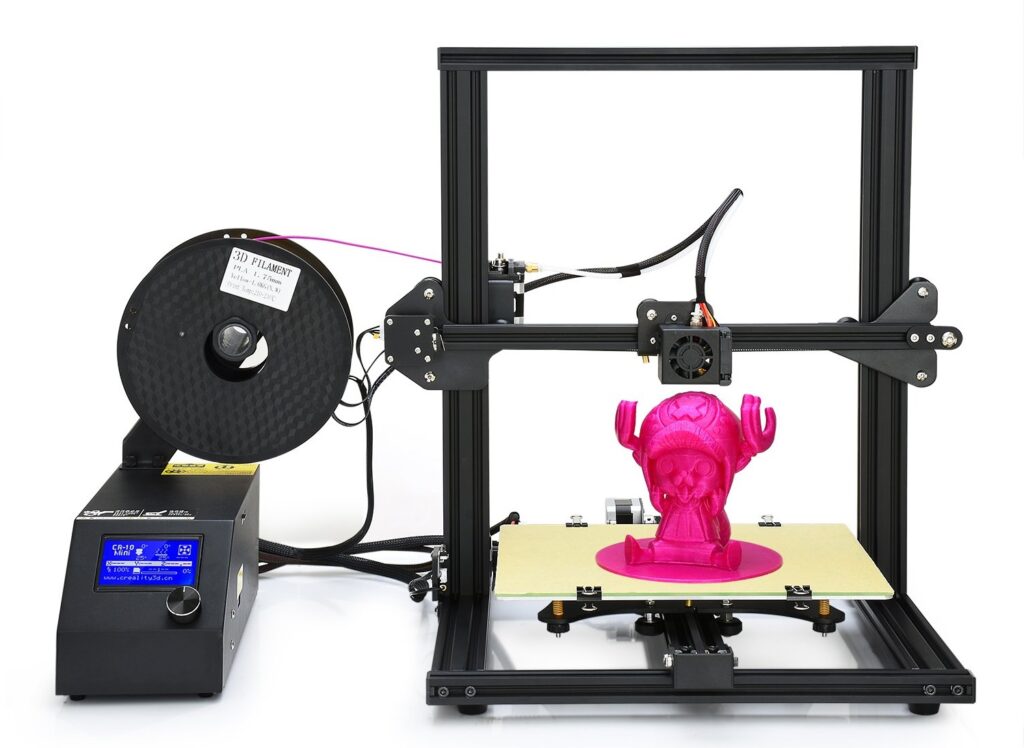

The Creality CR-10 is one of the best reviewed 3D printers on the market according to experts. Does it mini version match its hype? Well, considering its competitive price, myriad features and excellent reviews, the 3D printer is pretty great. It’s quite something to consider whether you are a beginner or already own a couple of 3D printers. The big news is that Creality chose to keep everything that made the bigger models great. Quite simply, the CR-10 mini is a full-featured 3D printer without the expense and inconvenience of the larger CR-10s.

At its convenient price point, it is hard to compete with the CR-10 mini. It offers a build volume that is 2 times bigger than what other mini 3D printers offer. Its full metal frame, acrylic base for support, heated print bed and Creality’s special print resume feature set it apart from others. This Creality CR-10 mini review will delve deeper into the unit’s features. Find out if it can catch up with its big brother’s CR-10 cult following.

The Creality CR-10 mini is a scaled down version of the very famous CR-10 produced by Creality, a Chinese 3D printer manufacturer. The mini printer packs a punch with incredible features just like its larger version. In fact, Creality only added the power outage protection and resume function on top of the CR-10 features. Here are the key features that distinguish the 3D printer from other mini models.

The CR-10 mini targets a new audience that would love to have all the features of a solid 3D printer without the inconvenience and expense that the large models come with. The mini printer is reasonably sized, offering twice the build volume of most standard mini 3D printers.

Its performance is also unmatched in the world of mini printers. Since it shares many of the great specs of the CR-10 family you will forget you own a mini 3D printer. It features a removable heated print bed, a fast printing speed of 80 to 100mm/s for most materials and is PLA and ABS compatible. In sum, the printer gives you everything you need to get started in 3D printing and with heavy modification, you can transform it into something really impressive.

The CR-10 V2 is an upgrade of CR-10 mini’s larger version the CR-10. According to experts, the CR-10 V2 isn’t a big enough upgrade worth its premium price point. The two models share so much in common in terms of specs and functionality, and like all Creality products, they both suffer from quality control issues. The CR-10 V2 has fewer issues out of the box and is more worthy if you intend to upgrade your CR-10 mini. It has a better frame stability, improved print bed, and build plate insulation. If you are on a tight budget, the CR-10 mini is the way to go as it has a comparable print quality.

Knowing the way your 3D printer is build you understand how it will perform at your working space.

When it comes to size the CR-10 mini dwarfs other mini printers. However, this doesn’t mean that it is bulky or has an inconvenient size like large 3D printers. Its size lives up to its mini label. At 16.5 pounds, you can easily carry the printer from one place to another without needing an extra pair of hands. Compared to other standard mini printers like the famous Monoprice mini, the CR-10 mini is a bit on the heavier side, but it won’t break your back.

Also, the unit measures 20 x 22 x 25 inches. It wouldn’t take much space on your desk or your already cramped craft room.

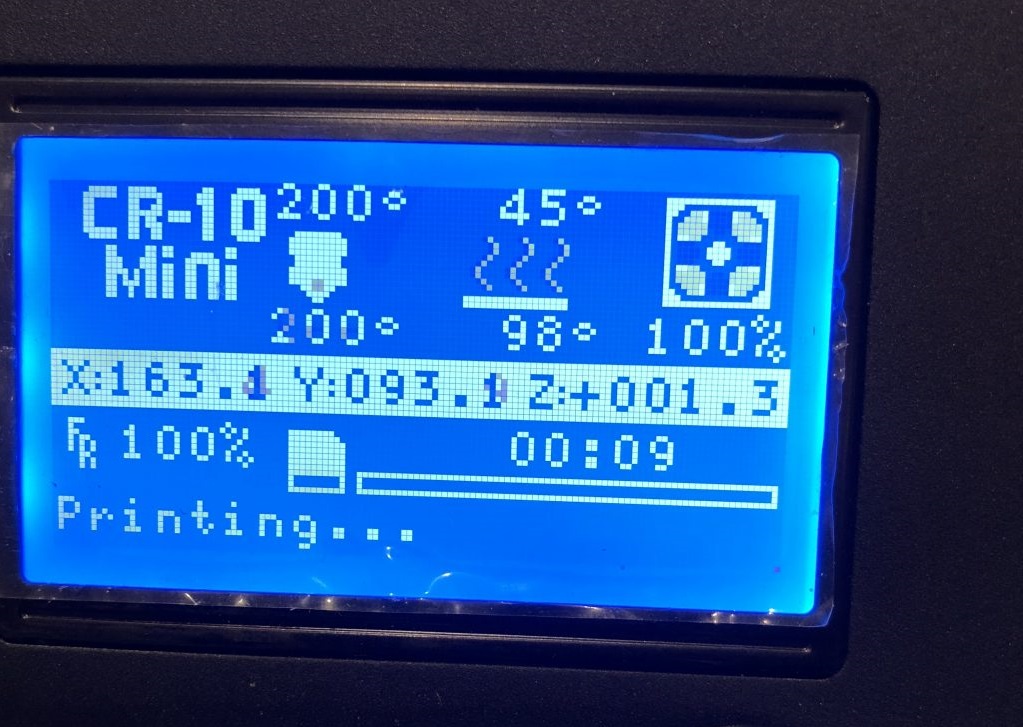

Just like the entire CR-10 family, the CR-10 mini has an LCD control. It is very intuitive, even a beginner will easily wrap their head around it. In case you are completely green, you can look up the directions on the user manual.

The CR-10 mini is compatible with a couple of filament materials including PBA, ABS, copper, carbon fiber, and wooden. The printer’s hotbed and nozzle heat up to high-enough temperatures that can print several filaments, thus, increasing your printing options. What’s more, the filament set up is very robust and works great. It allows you to feed the filament into the printer right next to the screw.

Bed leveling is pretty straightforward on the CR-10 mini as it is with its older brothers. It takes just a few minutes and once leveled, you would never need to re-level the printer’s bed unless you change its hardware or notice any issues with prints not sticking to it. All you need for the process is a sheet of paper. Experts recommend getting upgraded bed leveling knobs.

The process begins by heating the printer’s bed and nozzle to 60 and 210 degrees Celsius respectively. The next step is positioning the nozzle which involves homing the X and Y axes, moving 20mm toward the X and Y axes, then finally homing the Z-axis.

After positioning the printer’s nozzle you can go ahead to adjust the bed height. You can do this by sliding a piece of paper between the nozzle and the bed. This allows you to determine the adjustments you need to make. Next, adjust the thumbwheel under the bed corner. Keep adjusting until you feel resistance when sliding the piece of paper between the nozzle and the bed. Repeat the adjustment process for all the print bed’s corners and the center.

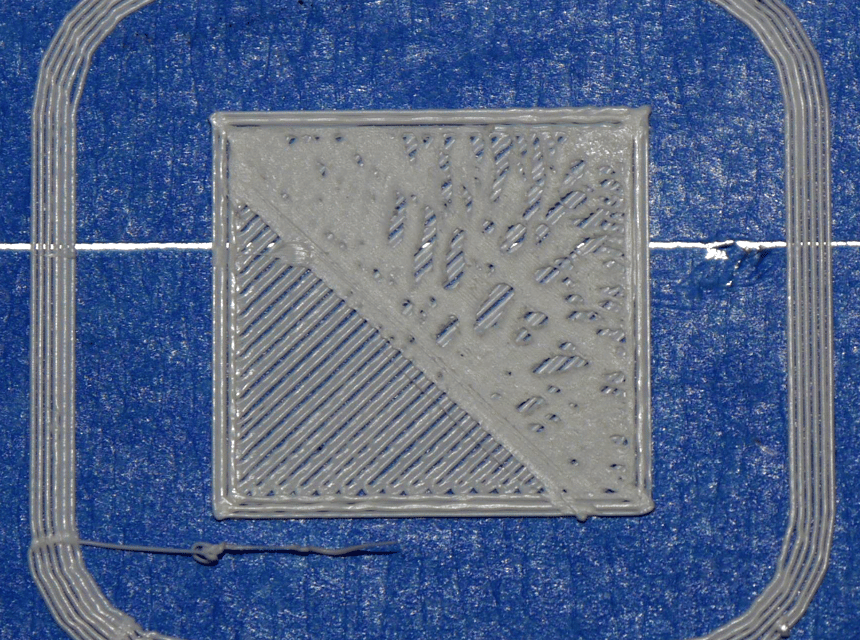

Once you are done with the adjustments you can verify that all the corners are at the correct height before running a test print to visually confirm that the first layer is printing well.

This is one of the factors you must consider when choosing a 3D printer whether you are considering it for minimum home use or you deal with large 3D prints. You want a printer that can give you high-quality prints but is also cost-effective.

Surprisingly, the CR-10 mini consumes a lot of power. It consumes 360 watts, and is the second highest consumer of all the Creality 3D printers after the popular CR-10 S Pro. Although it will be a bit costly to run the printer, its benefits outweigh the costs. Its print-quality is unmatched and it is packed with features that make it a high-performing and convenient unit.

Creality refers to the CR-10 mini as a kit but there is very little required of you when it comes to assembly. Technically, the printer comes pre-assembled as most of its components like motors and switches come already attached to its chassis.

You don’t need any mechanical knowledge to assemble the printer. In fact, if you have assemble furniture from IKEA or Meccano before, you are good to go.

The printer comes in 3 different components; the vertical chassis, horizontal chassis, and control unit. The first step of assembly involves bolting the 2 chassis components together. It is usually the most difficult part of the process because you are required to reach underneath the horizontal chassis to tighten the bolts and hold the vertical frame on top simultaneously.

The CR-10 mini comes with all its motors and heated bed wired into the control box. This makes setup a tad easier. All you are left to do is plug the small connectors to the motors and switches which is such a breeze as the connectors come with labels that you can match to the corresponding labels on the printer.

The final assembly step is checking if the power supply voltage is right for your country. Never assume it is pre-set correctly. In case you need to change, you can simply reach into the switch with a screwdriver.

Creality offers a 30-day return period and 1-year warranty cover. If you notice any manufacturing defects on your printer within this period, Creality will repair it or replace it for free. All the major parts like the motor, screen display, hotbed, and motherboard are all covered by the warranty. The extruder kits can be replaced within 3 months.

Learn more about Creality CR-10 mini’s functions by understanding how it operates.

The CR-10 mini utilizes the popular fused deposition modelling (FDM) which is a 3D printing technology that involves the material extrusion process. According to the latest research, material extrusion is the most inexpensive, and easily accessible 3Dprinting technology in the world today.

The FDM technology isn’t complex. Once you load a spool of filament into the 3D printer, the motor pushes it through a heated nozzle where it melts. The printer’s extrusion head then moves along particular coordinates while depositing 3D printing material on a build platform. The printer filaments cools and solidifies on this build platform to form a solid object.

The FDM technology is loved by many 3D printing enthusiasts because it offers the best surface finish and full color. Plus, it can be used with many different materials which are easily available. However, it is not the best for printing mechanical parts as it is brittle.

Once you have the Creality CR-10 mini in your hands, you will conclude that the term ‘mini’ is relative. When you compare the unit to the other members of the CR-10 family, it is very small, but when you compare it to other mini 3D printers it is quite large.

The printer offers a sizeable rectangular build volume measuring X300mm x Y220mm x Z300mm. This is significantly larger than most printers within the CR-10s price range. It has literally shaved off 80mm x 100mm from its older brother the CR-10. The build volume is adequate for most applications.

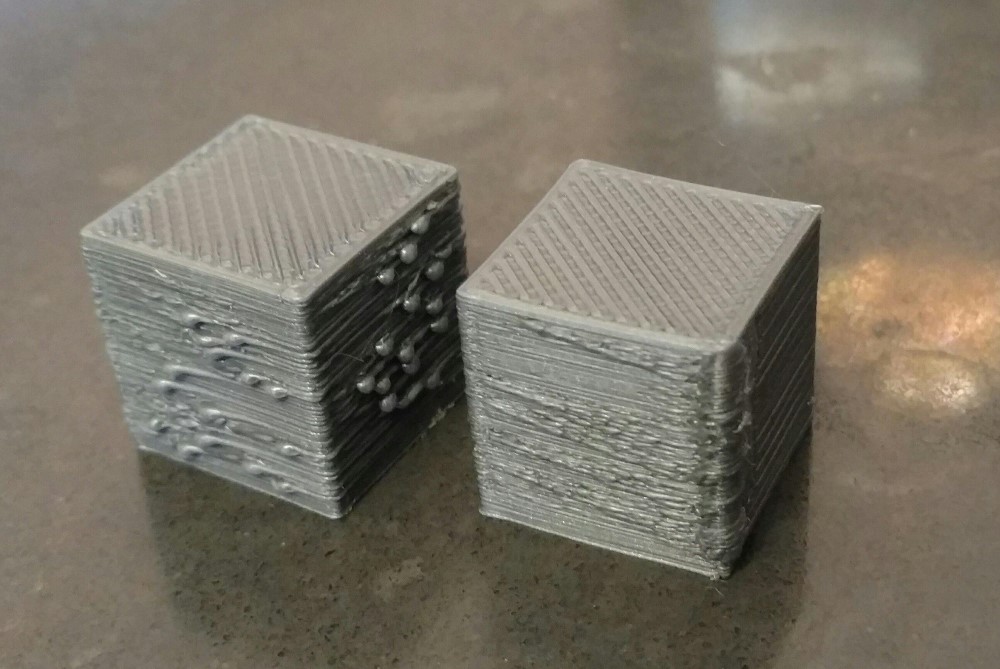

The print quality of the CR-10 mini is out of this world for a mini 3D printer. You will be impressed by its accuracy. Most users report that the details of their prints are exceptionally replicated without any blemishes or imperfections. Once you wrap your head around the printer’s functionality, you can optimize the settings to achieve high-quality prints.

Also, you wouldn’t wait forever to get your projects done. Creality allows you to enjoy fast printing speeds between 80 and 100mm/s for most materials.

Some users have reported their worries about the lubricant on the lead screw flowing into the hot chamber. You can buy aftermarket extruders to counter this issue. It would prevent the filament from touching the lead screw completely.

Auto-resume function- Very few mid-range mini 3D printers come with this convenient feature. The auto-resume function makes you printer remember your work whenever there is a power outage and it is in the middle of printing. When power comes back, it will resume printing from where it left.

Connectivity- the CR-10 mini features a micro SD slot. This means you can print your projects from an external media storage device.

Removable glass bed- You can easily remove the glass bed to pluck the print off whenever you have no patience. What’s more, Creality includes a spool of Kapton tape just in case you hate to print on the bed directly.

The only feature missing on the CR-10 mini that could make it a complete stellar unit is a filament run-out sensor. You only get to replace your filament when it’s finished and this can be frustrating for some users.

The CR-10 mini offers a big bang for your buck with a couple of accessories. It comes with a pack of tools, a TF card which has the user manual and software, and a 1.75mm spool of PLA filament. The filament weighs 200g and comes in random colors.

The CR-10 mini is not the cheapest mini 3D printer out there. It also isn’t the most expensive. Creality did great to give beginners a chance of experiencing high quality 3D printing at a reasonable price point. The price is very fair, given the unit has all the top qualities that the popular CR-10 has with an improved build quality.

Plus, it comes with a couple of accessories that offer great value for your money.

|

PROS |

CONS |

|

|

From our full-blown Creality CR-10 mini review, it’s quite obvious that the printer is unmatched. The only thing that works against the printer is its price point. Most 3D printing enthusiasts are skeptical about parting with 239 dollars for a printer with a mid-range printing volume yet there are multiple options with large printing volumes within the same price range. However, the top-performance and superior build quality of the mini justifies its price point.