The debate on direct drive vs Bowden has always lingered for long. Nevertheless, it’s not surprising why it’s so. If you’re looking to get an FDM printer, you definitely cannot avoid coming across these two terms: Direct Drive and Bowden Drive System. Newbies who are not so familiar with 3D printing may also find it difficult to understand and differentiate between these two.

So, what are Bowden and direct drive? What do they signify? Do they leave any remarkable effect on prints? Is there anything special about them? And more importantly, which of the two is better? In this direct drive versus Bowden guide, we answer all these vital questions to help you make a perfect choice.

The extruder system is what both Bowden and direct drive refer to. To be more specific, these two systems have their peculiarities in how they feed filament into the hot end and the extruder’s mounting location. They also have their respective downsides and upsides. But despite this basic uniqueness, they share the same function.

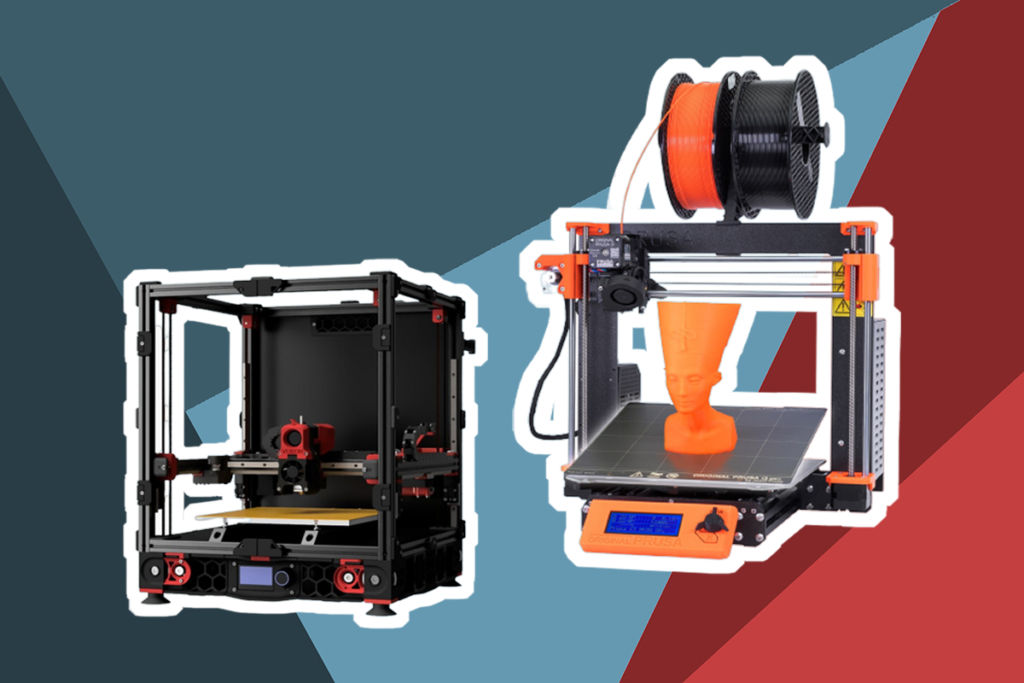

This system got its name ‘direct’ because of the direct interaction of the filament with the hot end. The print head assembly is where the extruder is attached to.

The path between the hot end and the extruder is quite short. This is the core feature that distinguishes the direct drive system. You may want to consider checking out the list of our best direct drive 3D printers to choose from some of the finest models.

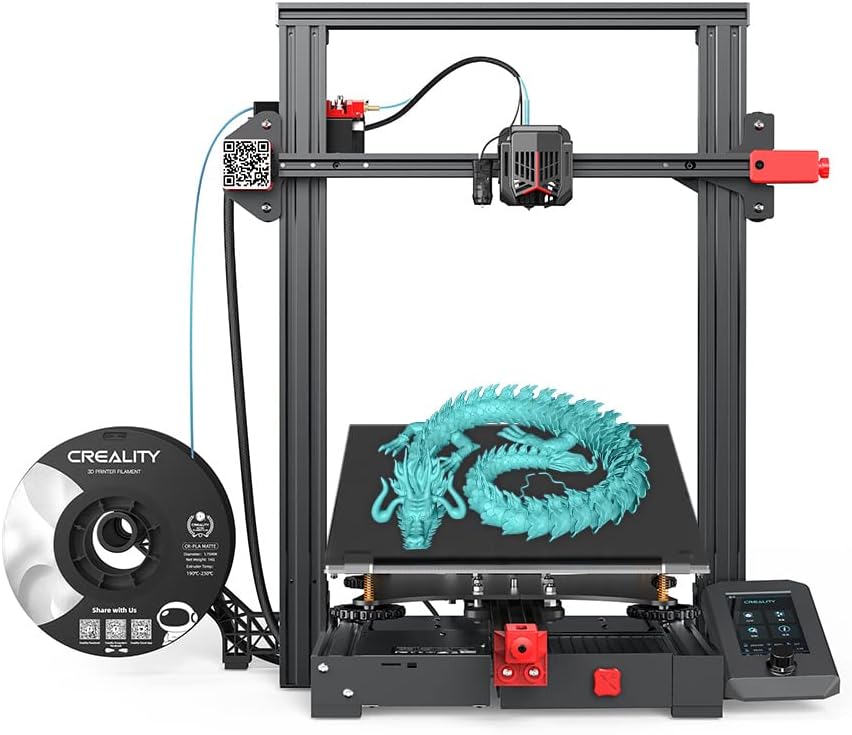

This Bowden extruder system got its name from the Bowden tube it uses. This is a long PTFE tubing that is used to feed filament to the hot end.

The frame of the printer is where the extruder is mounted on. Unlike the direct drive setup, this Bowden extruder setup has no direct leverage. Due to that, there’s a much longer path existing between the hot end and the extruder. Creality 3D Assembled Hotend Kit Extruder is an excellent example of a Bowden extruder system.

After having an idea of the basic difference between these two extruder setups, you should also know where their strengths and weaknesses lie.

You enjoy smoother travel movements due to the lighter print head of the Bowden setup. The print head isn’t fit to deal with too much weight because the extruder is fixed to the frame. This means that a Bowden setup will make you enjoy less vulnerability to layer disproportion, more precision, less jerk, and improved efficiency.

The print speeds are higher, and the surfaces are cleaner. To include, during travel movements, there’s less pressure on the stepper motors. This makes Bowden printers operate more quietly.

A direct drive setup, on the other hand, has the print head assembly and the print head joint with the extruder. This puts the printer under more stress and makes it prone to wobbling, overshooting, and vibration.

All of these tend to impact the accuracy and quality of the print. Most times, people who prefer the direct drive system use printer tuning and correct slicer settings to keep things well-balanced. You can also check the list of our best high-resolution 3D printers if you’re most concerned about high quality.

The Bowden system may beat the direct drive system in terms of speed, but when it comes to extrusion, the direct drive system is the boss. All thanks to the location of the extruder, the direct drive system performs well with less aggressive slicer settings.

More so, it doesn’t utilize a high degree of motor torque. Plus, it’s very responsive. This impressive functionality is noticeable in the responsiveness of the Creality 3D CR Touch Auto Bed Leveling Sensor.

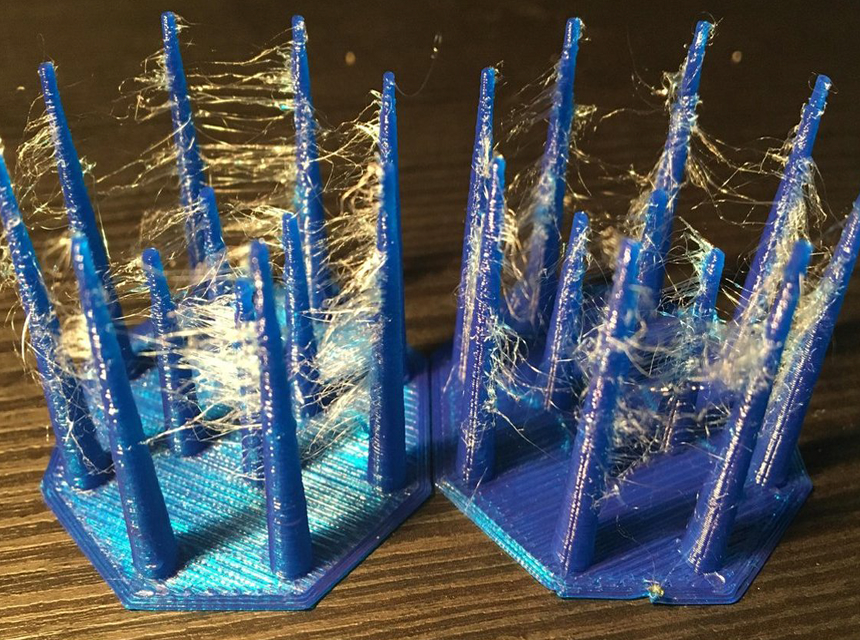

Speaking of the Bowden system, filament movement isn’t easy. There’s a need for more motor torque. Likewise, the extrusion control isn’t responsive, and the precision isn’t top-notch. As the filament runs on the PTFE tubing, there’s usually some friction or resistance. Since the filament path isn’t short, there’s a high likelihood of delays or lags.

Retraction is a very significant action that can impact your prints’ overall quality and finish. It can also cause stringing and oozing reduction.

Speaking of retraction performance, you’ll enjoy improved and faster retraction with a direct drive system. All thanks to the proximity of the hot end to the extruder. Stringing is reduced, and the retraction control comes out very pleasing because the filament retraction is a smooth process.

A Bowden system, on the other hand, will require more extreme in-slicer tuning to cope with the less responsive and slower retraction. Accurate retraction is a tough job for Bowden systems.

If you’re planning to print abrasive materials and flexibles, especially TPU, direct-drive extruders are your best bets. You can’t go wrong with them because of their shorter filament path, better retraction, and high precision of filament control.

However, Bowden systems are not the best options for materials like those. You tend to struggle with clogging and jamming intermittently if you use a Bowden system for abrasive or flexible properties.

While you may experience distressing stringing and ooze with those materials, ABS and PLA work perfectly on a Bowden system.

Nevertheless, some artists love roughing Bowden extruders with flexibles by mitigating problems that may likely arise through printer mods and optimal settings. But even with that, the entire problem cannot be avoided.

In a nutshell, here are the good and the ugly sides of the direct drive;

The Bowden extruder does have its remarkable benefits, but it also has its downsides as well.

Here are some frequently asked questions about the direct drive and Bowden systems. J

1. Is a Bowden Extruder Better?

This response is subjective. You’ll find a Bowden extruder to be the option that will suit you better and give you pleasing results if you love higher speeds. More so, Bowden extruders will do great for your PLA/ABS materials. And the prints will come out very nice because there’s little or no vibration like the direct drive system.

2. Is Direct Drive Really Better Than Bowden?

Again, your preference determines which is better for you and which isn’t. Nevertheless, people who consistently deal with flexibles find direct drives the better option. Additionally, the better retraction and reliable extrusion of direct drives make them a favorite of many.

3. Does Direct Drive Help With Stringing?

It does. Direct drive extruders massively reduce the instances of stringing.

It can be very tricky to choose which to go for, between a direct drive and a Bowden system. Nevertheless, understanding the differences between these two extenders will help you make the right decision.

The best ender 3 upgrades may support either of these two systems. But before deciding what works best for you, consider the necessary factors. How important is speed to you? Or are you prioritizing extrusion?

Perhaps, you may plan to work with a certain series of filaments. And you’ll definitely need the perfect setup for your print. With this Direct Drive vs Bowden guide, we believe you’ll be able to make the appropriate decision that will make your prints come out excellently. Good luck.