3D printing is no more a fantasy nor an idea. It is now a physical part of our lives. With a 3D printer, you can bring your ideas to life or duplicate almost any 3D item. But as much as 3D printers seem to be able to solve all our problems, there is just one issue – heat creep. Heat creeps can happen right before your eyes, and you won’t know until your printed items tell it off. And worst of all, they can be very disturbing and difficult to get rid of. They can also destroy your printer if it is not attended to on time. It is alternatively referred to as the lurking internal problem. However, the good news is that they can be fixed and prevented.

In this guide, we will explain what heat creep is, the part of the 3D printer that it affects, how it is caused, how it can be detected, and how to fix it. So, if you want to know how you can save your 3D printer from heat creep, keep reading!

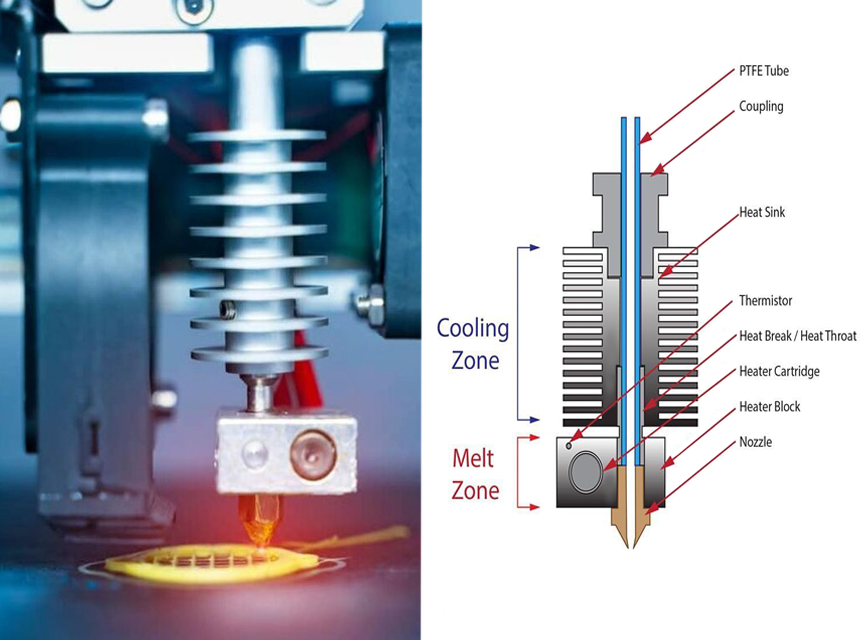

We cannot fully explain heat creep until there is an understanding of how Trusted Source Opinion: The 3-D printing revolution will blow you away - CNN A company in China reportedly used giant 3-D printers to make 10 houses in one day. This leads to two obvious questions. First, how big were those printers? The answer is: 10 meters wide by 6.6 meters high. A mixture of cement and construction waste were sprayed to build the walls layer by layer. edition.cnn.com a 3D printer works – referring to the hot assembly. It is also where many problems with printing occur, and if you are unfamiliar with this part of your printer, you might face many challenges with your printing. The hot assembly can be divided into 6 main components:

Now that we have identified the components of the printer, we can move on to what heat creep is.

Heat creep refers to how excess heat travels up the hot assembly (from the tube to the throat to the heatsink, heat block, and the nozzle). Then, this excess heat makes the filament melt much earlier than when it is needed. Though this is more common during printing when the temperature is at the highest, it can also happen after the item has been printed.

But why is this a problem? It is not easy to detect (especially if you are not a printer guru and you only know how to print stuff). It is also very frustrating to get rid of. By the time you finally begin to see physical proof of its existence, it would have done much damage that you might need to replace some parts in your printer. It also doesn’t give out gradual symptoms. Your printer would normally be working until the creeping swell causes a jam. You would have to stop your printing and immediately look for ways to repair it. That is why we are very interested in pointing out how you can prevent it in the first place before it happens.

Every problem is caused by something, and for heat creep, it’s a number of things. All of them cannot be the reason you are experiencing heat creep with your printer, but when you do a thorough check, it would be one or two of the following:

Now that we know the causes of 3D printer heat creep, we can move now to how it’s fixed.

With the things listed as the cause-effect of heat creep, you can pretty much guess what the solutions will be. But instead of thinking of these things are solutions when you experience heat creep, take them as preventive measures so that you won’t experience heat creep at all. That way, your printer stays healthy, and you can save unnecessary costs. So, what are the ways to fix all 3D printers‘ heat creep?

Since heat creep occurs when heat within the filament is too much, an obvious solution would be to reduce the temperature. High printing temperature, otherwise known as high hot end temperature, means that the heat block which is carrying the heater cartridge is also carrying excess heat. The excess heat can then travel up to the other parts of the hot assembly and melt the filament inside – heat creeps.

To solve this, you can lower the temperature so that you’ll prevent the heat from creeping up the hot end assembly. But if your printer is within the normal temperature range, then a high printing temperature might not be the problem. You would have to look for another solution.

This is another thing you can check. If your printer’s fan is faulty, inconsistent, or not powerful enough, heat can build up within the hot assembly and melt the filament within. To solve the problem, fix the cooling fan or replace it with a fan that’s more heavy-duty. But before you hurry to a repair shop, check first that your fan is set at the maximum speed. And if it is needed, increase the extruder fan setting. But if you are still experiencing heat creep after you have increased the fan speed and fixed any fault that might be there, then you would need to replace it. And when you are buying a new one, buy one that is fit for the amount of work it is doing.

Every printer comes with a default setting on the retraction length, but sometimes, this can be too far and can cause the filament to be too close to the hot end. Retraction in a 3D printer refers to the process whereby the filament is pulled back to improve printing quality. However, this can become a bad thing when it is pulled too far back. The filament can begin to touch the walls of the heat sink and melt early. You can reduce the retraction length automatically using the slicer settings on the printer. If you have done this and there is still no improvement, then there are two other things that you can do.

Another thing that can make your 3D printer emit toxic gases Trusted Source 3D Printers May Be Toxic To Humans The studies, presented at the 2020 Society for Risk Analysis virtual Annual Meeting on December 15, showed that the particles released during the printing process can affect indoor air quality and public health. www.forbes.com with heat creep is if the heat sink is dusty. Since the heat sink is the part of the printer that keeps the heat from reaching the filament, it is also the part that regulates how much heat reaches the filament. But when it is dusty, it affects how effective the sink is.

The temperature could be out of balance, and too much heat can reach the filament and cause it to melt. To fix this, clean the heat sink regularly. And the best way to do this is to bring out the cooling fan and the heat sink, then use compressed gas to blow off all the dust particles from within it.

Again, if you have done all the things mentioned above and you are still experiencing heat creep, then this is the way to go. It means that the cause of the heat creep is a slow printing process. When the printing process is too slow, heat has the same one to travel past the hot end and into the filament. But when the printing process is fast, there would be consistency with the flow of heat, and it is less likely for heat creep is less likely. However, it is best to note that when the printing speed is too high, other printing issues may arise. So it is best to keep the printing speed to a moderate level.

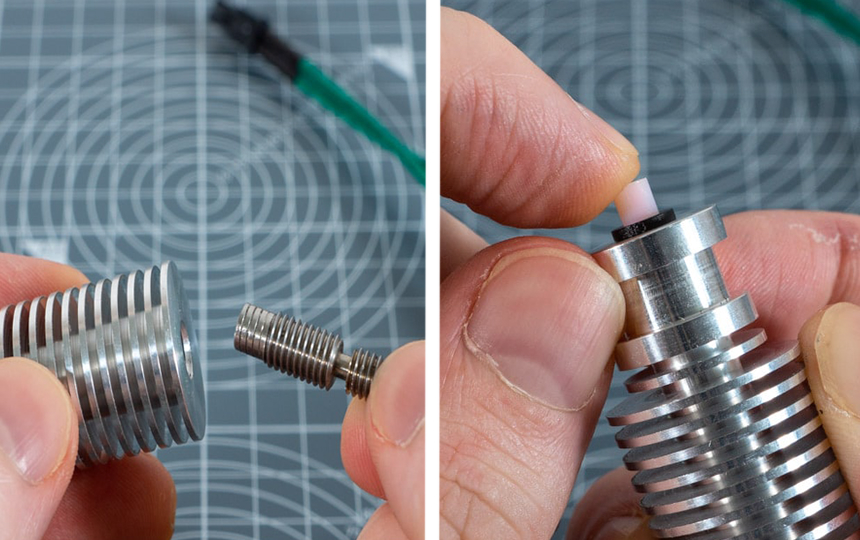

The heat break printer gets clogged once in a while, and it’s not something to worry too much over. Getting rid of this clog block is simple as long as you know what to do. There are two ways to fix the clog from a heat break printer.

Use a drill or a small screw to remove the stuck material so you can brush it clean. Make sure that the drill is not too tight or too loose so that you don’t damage more things. And after you are done, assemble all the parts back in place.

Apart from using a drill or any other similar substance to remove the clog-block, you. They also use high heat to melt the plastic. Butane gas has been reported to be very versatile in heating plastics till it’s melted. But again, be careful when dealing with high heat or gas.

Since heat creep cannot be seen with the eyes, it is best to check your printer regularly for things that can cause heat creep. Make sure that the fan is working at maximum speed and that the printing speed is not too slow. Also, clean the heat sink and fan so that you don’t clog up your printer. Check the retraction length and make sure that it isn’t too far back so that it doesn’t melt the filament way too early. Taking care of a 3D printer is a big job and if you happen to have missed these pointers, check for air bubbles on the filament when you pull it out. That’s an intense symptom of a printer with heat creep.

Heat creep destroys your printed item, wastes ink, and frustrates the owner. But at the same time, it isn’t a problem without a solution. We have listed the solutions above but if you wish to avoid the whole situation entirely, prevent heat creep by maintaining your printer properly with regular check-ups. Take care of your printer, and it will deliver the best results.