In general, PETG is the rival of ABS in terms of hardness and durability. You’ll discover here in this PETG vs ABS filament article the differences between the two. The ABS, an acronym corresponding to the acrylonitrile butadiene styrene, was one of the first materials used for the 3D printing technique by fused deposition modeling, or FDM. Today, it is one of the most common plastics and is used in processes such as injection molding to create all kinds of objects, from airplane seats to LEGO pieces.

When the PLA appeared on the scene, it dethroned the long-time “king” in its most general uses. Currently, polyethylene terephthalate glycol-modified (PETG), threatens to unseat it also for those applications that require high toughness.

The various PETG blends, or “copolyesters,” are described as the perfect balance between the toughness of ABS and the ease of use of PLA.

Acrylonitrile butadiene styrene (ABS) is a filament that in theory is perfect for projects with high demand and resistance to temperatures and forces. It has great resistance to impact, but it has a great handicap: printing it is horrible.

ABS warps a lot. But, there is an alternative to it: the ASA. Acrylonitrile-styrene-acrylate (ASA) has very similar properties to ABS and is also resistant to UV light, has less tendency to warp, and produces fewer “harmful” gases.

ABS is the second most used plastic in 3D printing. Its mechanical properties are better than PLA, although it is more difficult to print than PLA.

You can use this material for projects that need to support more than 1 kg of weight and be outdoors. This type of filament can be used for most brands of printers, for example, MK3, Monoprice FlashForge, Ender 3, and more. A typical example of this versatile filament is the PETG Filament 1.75mm Filament from Overture. It’s ideal for a 3D build surface of 200 x 200 mm and weighs 1kg (2.2lbs).

It can also be used for parts in harmful environments such as chemical factories or high humidity. ABS filament can be used for making everyday items such as customized phone cases, salt shakers, wallets, candle holders, dog tags, and sculptures. One typical example of this type is the HATCHBOX ABS 3D Printer Filament. It is a 1 kg spool with a dimensional accuracy of +/- 0.03 mm.

To give you an idea of how hard it is, it is the material with which the Lego pieces are made. It dissolves well in acetone. You will notice that ABS dissolves and smooths much better.

You should use ABS once you have mastered printing with PLA since it is difficult to print due to its strong shrinkage in the face of temperature changes (warping). Despite that, its technical characteristics make it perfect for parts in harmful environments (mechanical stress, high temperature, etc).

The good thing about ABS is that it is cheap, so if you get the hang of warping quickly, you ventilate the room well and control sudden temperature changes in the pieces.

You can print supports, tool handles, or chassis for your robots at a very low price. In addition, you can polish the pieces using acetone steam, leaving a very cool porcelain effect.

The main advantage of ABS is its low price. Usually, its cost per pound is lower than that of other filaments, but it’s not as low as PETG. ABS withstands more heat than PETG. It is also lighter, so the coils last longer.

On the other hand, ABS does not offer a great deal in terms of variety. When you print it, there is a property called “warping” that causes the material to shrink as it cools, and ABS, in particular, has a lot of it, making it impossible to print large pieces of this material on open printers.

It is also somewhat more expensive.

PETG is an acronym for polyethylene terephthalate glycol. It’s a Polyethylene Terephthalate (PET) that is glycol-modified. PETG is the brother of PLA for certain cases.

PET is a plastic widely used in the plastic injection industry for its durability and resistance. But it has a problem: It does not print very well. That is why PETG (‘G’ for glycolized) was developed, to make it easier to print or PETT, famous for being translucent.

PETG is the filament that has replaced ABS to make parts for 3D printers (Prusa MK3 printers are made with this material today).

It is just as easy to print as PLA, less fragile, and more thermally resistant. In conclusion, if you are looking for more ductility and more resistance to temperatures, it is convenient to use PETG, but in terms of resistance, PLA and ABS still deserve more.

You can use PETG, for example, for 3D printer parts (due to the temperature they have to withstand and their ductility). It’s a good alternative to ABS in garden parts that support weights of less than 1 kg.

On the other hand, if you are going to make a piece that needs a bit of elasticity and resistance, this is the ideal material. Despite having less resistance than PLA, it is somewhat more flexible. To give you an idea, PLA is candy, and this is candy with bubble gum.

The PETG filament is the material with which Joseph Prusa’s Prusa I3 is made. It used to use ABS, but because it is easier to print, it switched to PETG (as do many 3D printing services).

However, PETG has problems such as that it is more expensive, easily absorbs moisture, and is somewhat stickier when printed, so the supports are less removable. Still, once you get the hang of it and are careful to store it in a dry place, PETG is a great (albeit slightly more expensive) alternative to ABS.

PETG is the only filament material that is available in transparent colors, which are useful for the construction of objects such as lampshades and vases. ABS does not offer this possibility.

Additionally, many manufacturers offer PETG-based blends and varieties. These have different names, like CPE from Ultimaker and nGen from Colorfabb, but they all use PETG as the base material.

There are varieties of PETG of all prices, from filaments for daily use to others of premium quality, especially in the case of those mixtures that offer more hardness or higher print quality.

The downside is that it is more expensive. On the other hand, it has more “stringing” than PLA (the threads that form between columns) and its impact resistance is not much greater than PLA.

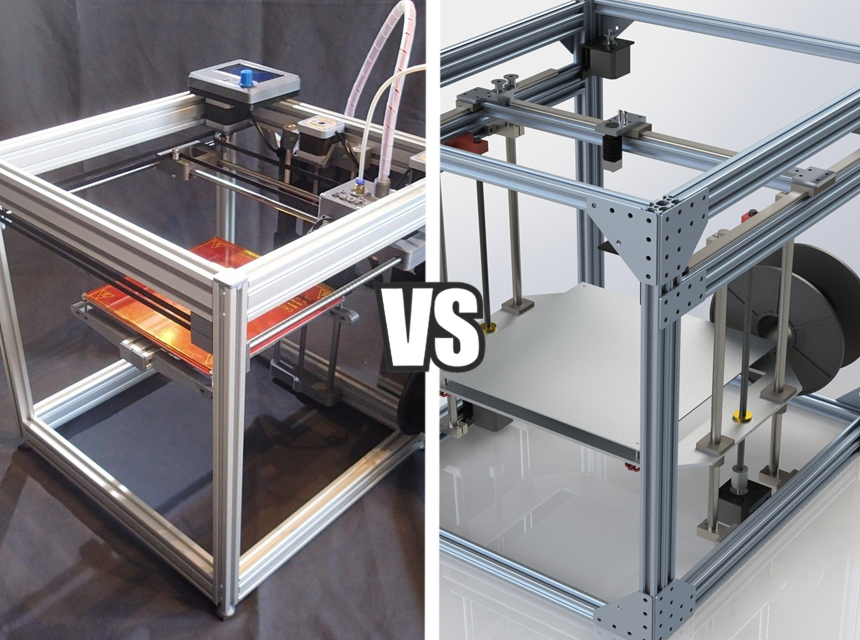

Compared with each other using various criteria, below are how PETG differs from ABS. Followed by this is a side-by-side comparison table that makes the differences even clearer.

While it can be hard to make ABS stick, PETG often sticks so well. ABS is known to be difficult to print. That’s why PLA managed to get ahead of it, and it’s also what makes PETG such a powerful competitor.

One of the biggest problems with ABS is its poor adhesion, both to itself and the printing surfaces. This is why it is imperative to work with print beds that are heated to 100 ° C or more, as well as hot build chambers, which can make the difference between the success or failure of a print. Poorly heated prints noticeably warp, warping and flaking the build plate, and even cracking between layers.

In that sense, the PETG is much more permissive. Warping is drastically reduced with this material, and the filament only requires a print bed with a temperature between 50 and 80 ° C. The adhesion to the bed is often too good, to the point of tearing chunks from the printing surface. This problem is easily solved by coating the build plate with a release agent, such as glue or hairspray. This practice ensures proper prints. Parts only crack when the fan speed is too high, which is easy to compensate for. No need to use hot build chambers.

In short, it is much easier to achieve proper prints when using PETG filaments, as this material avoids many temperature-related print defects.

From a health point of view, PETG is much more recommended. During printing, it emits minimal odor and emits few volatile organic compounds (VOCs) and particles.

ABS, however, can generate all kinds of odors, from mild to intense, and emits large amounts of particles, which can be harmful to health. You definitely shouldn’t be in the same room as a printer creating ABS parts.

ABS is much more vulnerable to temperature problems than PETG. In addition to the likelihood of print failure, its temperature requirements can also be very demanding on your 3D printer. Nonetheless, Creality type printers are built to be able to print PETG.

Not all printers can reach the extreme bed temperatures required by ABS, which often well exceed 100 °C. And even fewer models have heated build chambers.

ABS also requires a much higher head temperature, beyond the reach of PEEK-based and PTFE-lined hotends.

To print with ABS, you need to use an all-metal hotend, such as the E3D V6. This is not necessary when working with PETG.

ABS stands out for its flexibility for post-processing. Both PETG and ABS can be worked with typical metalworking tools such as deburring tools and wrenches, but ABS offers some additional advantages.

In particular, it is easy to paint and paste. On the contrary, these tasks are almost impossible with the PETG. This is especially relevant for large pieces that you plan to give a cosmetic finish to, as working with PETG can be torture. When it comes to post-processing, ABS wins the hand.

PETG ousts ABS in terms of strength. Traditionally, ABS has been the material par excellence for applications that required toughness, but PETG has arrived to make it the competition in that regard.

Many users have already found that ABS is much less resistant than PETG, especially when the loads are in the same direction as the lines of the layers since the adhesion of the layers in ABS prints is lower.

With the advent of new materials, the toughness of ABS in 3D printing applications has become a mere myth. In that sense, there is no reason to choose ABS over PETG.

ABS shows a slight lead in temperature resistance. While most PETG can withstand temperatures up to around 80 degrees celsius, ABS can go up to 100 degrees. The margin is small enough that PETG is suitable for most electronic applications, but only ABS can resist boiling water, which is especially useful if you need to sterilize your print.

In terms of temperature resistance, ABS offers a slight advantage.

In the long run, PETG responds much better to sun exposure. The effect of ultraviolet radiation on this material is minimal. The ABS, on the other hand, weakens significantly. If you are looking for a material for use outdoors, PETG offers you a longer duration.

For parts in harmful environments, although PETG also holds up well, ABS is usually stronger, more durable, more reliable (like ASA). On the other hand, if you are looking for lace pieces, which can also be in somewhat harmful environments (such as on a terrace in the sun), but you are not looking for that durability because it is not really subjected to a lot of stress, the PETG prints easier, and it is a better option.

Their environmental impacts are some of the reasons you have to avoid ABS. ABS is petroleum-based and is a non-biodegradable plastic. It’s therefore not environmentally friendly. PETG also has a negative environmental impact when not disposed of properly. However, the good news is that you can recycle both materials.

ABS is much easier to store. PETG is significantly more hygroscopic: it easily absorbs moisture from the environment. This moisture deteriorates the material itself and can damage a coil or filament that was in perfect condition.

Therefore, ABS is much less sensitive, and we can simply store it on a shelf.

ABS used to be cheaper than PETG, but not anymore! A kilogram roll of PETG can be gotten for as low as $16 today while the same ABS costs around $20.

Here is the general breakdown of how PETG and ABS differ:

| Property | ABS | PETG |

| Price (per kg) | $20 – $25 | $16 – $19 |

| Melting temperature | 220–240 °C | 230–250 °C |

| Hotbed temperature | 90–110 °C | 60–90 °C |

| Density g / cm3 | 1.07 | 1.27 |

| Ease of printing | Very low | High |

| Print quality | Medium | High |

| Strength | Medium | Medium-Low |

| Stiffness | Medium | Low |

| Impact resistance | Very high | Medium |

| Thermal resistance | Very high (<100 °C) | High (80 °C) |

| Adhesion between layers | Low | High |

| Odor | Much | Very little |

PETG comes under a wide variety of names and blends. ABS used to be the most common material but has gradually been replaced by PETG. Both materials offer slightly different options in terms of colors and varieties.

For most users, there is no compelling reason to choose between ABS and PETG. PETG is harder, more durable, and prints better. In addition, it is available in transparent colors.

ABS is only essential if you need your print to withstand temperatures of 100 degrees celsius or be able to be painted and glued. Otherwise, it is difficult for you to compensate for your printing difficulties. So, with our detailed PETG vs ABS Filaments comparison, it looks like the former edges the latter.

We hope this guide helps you differentiate between both types of filaments for your personal use.