Who invented 3D printing? This is an interesting question, this process has been lauded as the future of manufacturing and it has matured a great deal over the last decade. The earliest examples in fiction are the replicators in the Star Trek Generation TV show. But, in reality the invention of 3D printing was less dramatic and yet who knows what may be possible in the near future. In this article we will look at the early days of 3D printing, its ongoing development and the state of this fascinating manufacturing process today.

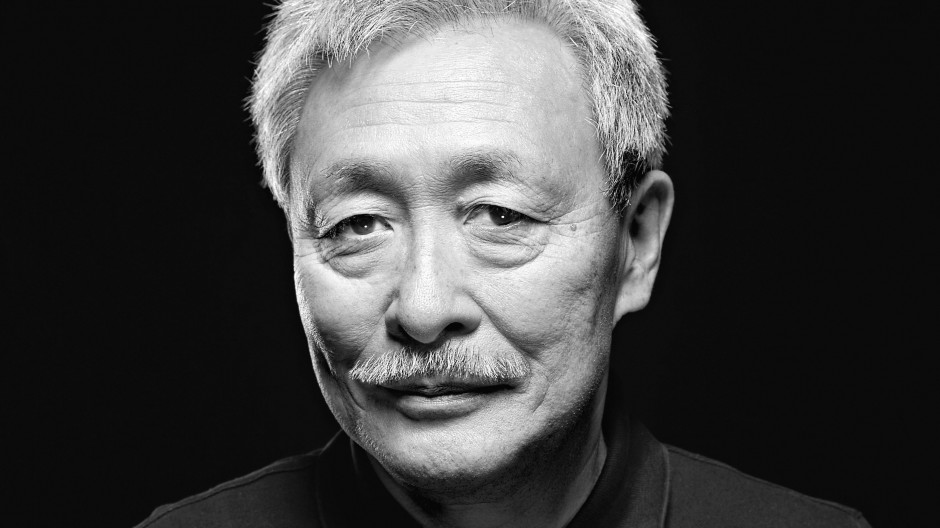

Who created 3D printing is an interesting question, because it would be fair to say that there were two pioneers that led the way. The first is Hideo Kodama from the Nagoya Municipal Research Institute in Japan who was the first person to publish a paper on the hardening of photopolymers after exposure to UV light and how these materials could be used for fabrication. The second man was the first person to actually put these ideas into action.

In 1984 Chuck Hull designed and built the first ever 3D printer.

Competition for the creation of the 3D printer was hotting up and only three weeks after the patent filing, a team of three French investors filed a similar patent. But, the efforts of Alain Le Méhauté, Olivier de Witte and Jean Claude André were thwarted when their employers made the decision to abandon the research. Chuck Hull was now able to copyright “Stereolithography” as a term and his patent was titled “Apparatus for Production of Three-Dimensional Objects by Stereolithography ” in 1986. The same year, Chuck Hull formed a new company in Valencia, California. He named his company 3D Systems and began commercial prototyping services.

So, who invented 3d metal printing? We’re getting there. Hull’s patent covered a lot of 3D printing potential in a very short and productive period time. But, other inventors quickly grasped that this technology could be used to fabricate with other materials too. Carl Deckard, a graduate student from the University of Texas, filed a patent in 1989 for Selective Laser Sintering or SLS. A laser was used to custom-bind powered materials, including metal, together to create layers of an object. The fresh application of successive layers could ultimately create simple metal objects.

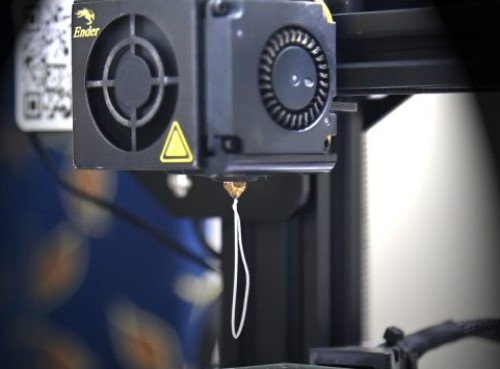

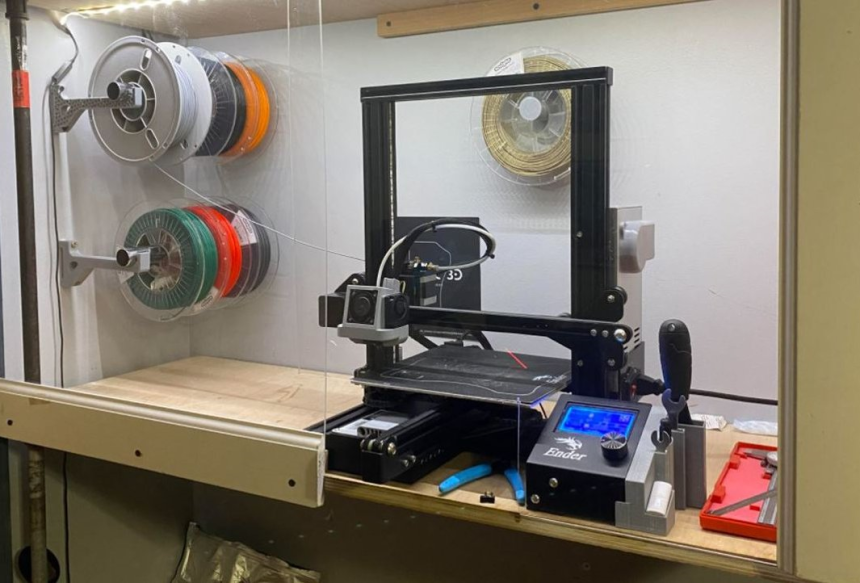

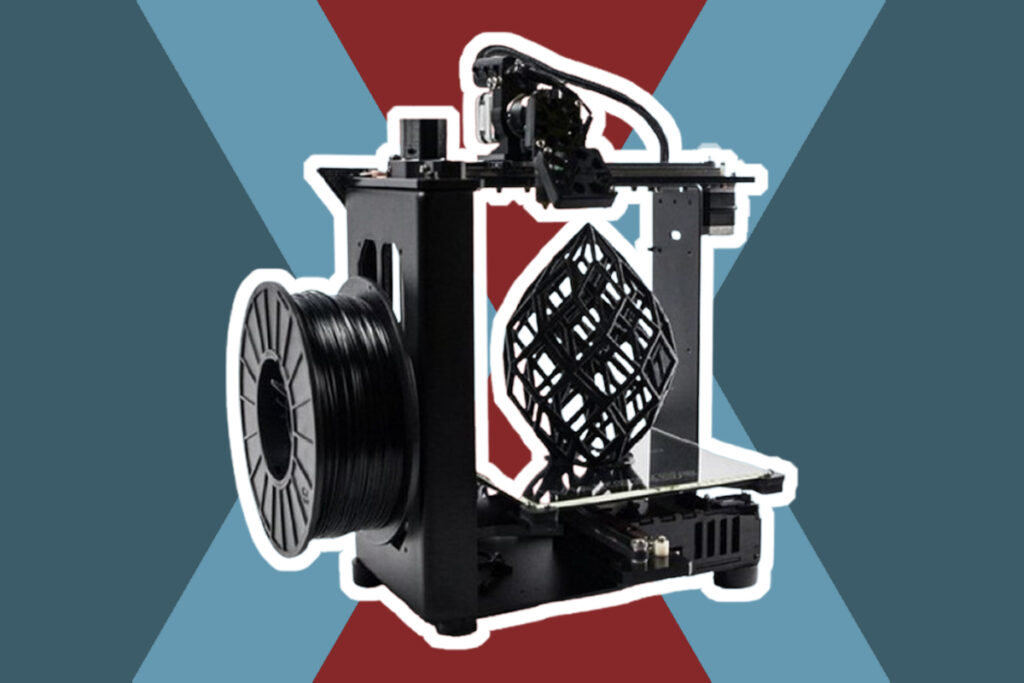

Modern products, such as the Creality CR-10S FDM 3D Printer can be directly traced back to fused deposition modeling or FDP which was developed by S. Scott Crump in 1988. Crump was an inventor that got the idea of a moving building platform after experiences with a glue gun and candle wax which he used to make a toy frog for his daughter. The resin material was laid onto a building platform through a metal wire and then it hardened almost immediately. Crump patented his invented 3D printed technology in 1989 and then co-founded Stratasys Ltd. with his wife. The company went public in 1994 and in 2003 they were selling the best 3D printer for architects and rapid prototyping.

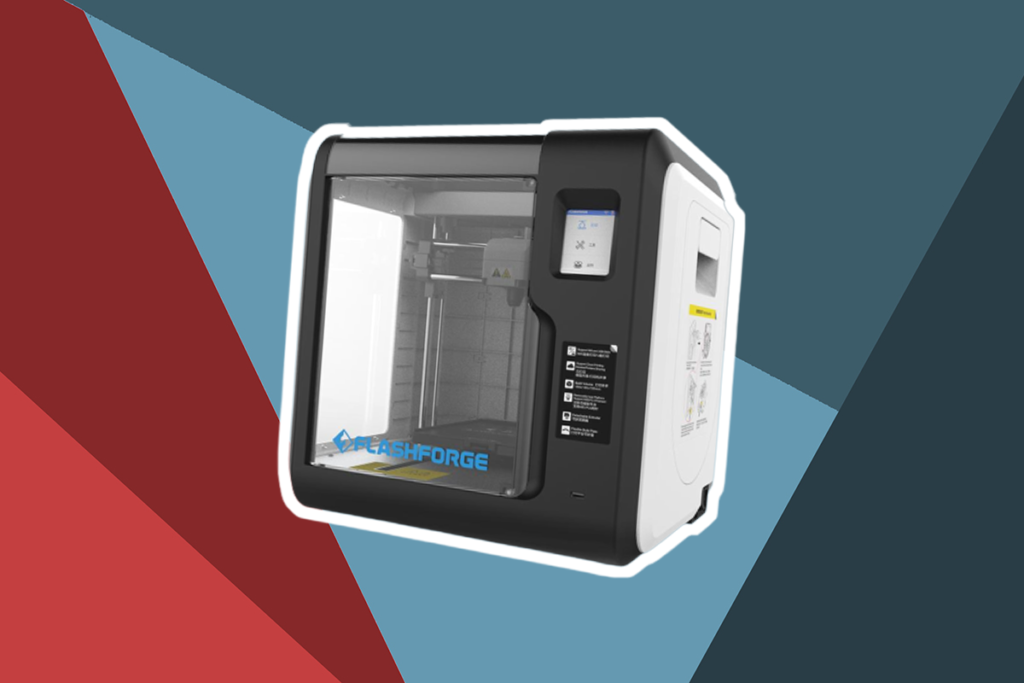

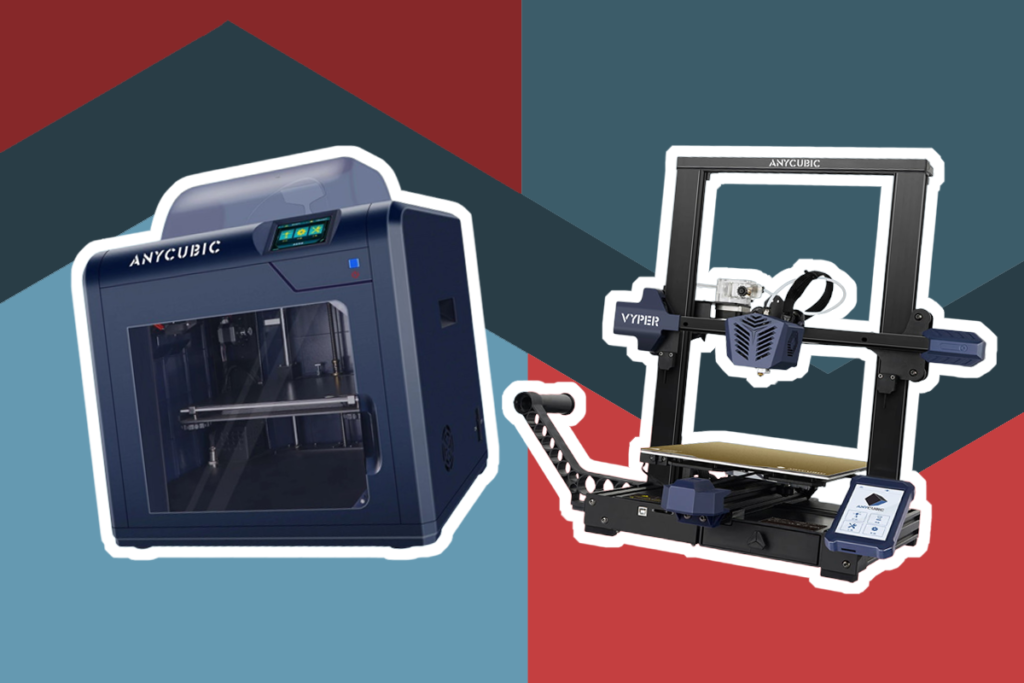

Many people search for the best 3D printers for beginners and then consider products such as the ANYCUBIC Photon D2 DLP 3D Printer. This may seem trivial, but it really does demonstrate that this is now a mature and widely adopted technology. There are many platforms and printing processes on the market and additive manufacturing has seen a significant uptake since 2010. The initial MakerBot hype has ceased and the invention of FDM 3D printing and other techniques has really found its groove.

Many industry experts believe that additive manufacturing could replace CNC and milling manufacturing processes in the very near future. A Lux Research report from 2021 predicted that the 3D printing industry will be worth $51 Bn by 2030.

We are now at the stage where 3D printing is only limited by the imaginations of the inventors and engineers that are using the technology. A recent project from scientists at the University of Southampton produced the first ever 3D-printed drone. Another project produced a 3D-printed car, which was powered by a hybrid gas/electric engine and the fuel consumption was an impressive 200 mpg. Another startup has focused on the production of ecologically friendly living structures and they ultimately created a habitat that could be used on Mars!

In the developing world, we are already seeing 3d printing used to create affordable housing and emergency shelters in disaster zones. At the high-end of additive manufacturing, certain processes are being considered for the production of larger structures. The powdered materials are fused with lasers or the direct application of heat to create metal parts. At this time, this process is expensive because it requires specific infrastructure that is not affordable outside the heavy manufacturing industry. Advances have been made in micromanufacturing with applications, such as self-powered prosthetics, articulated limbs, smart robotics and more. Who invented 3D printing? This is certainly a compelling topic, but the future of additive manufacturing is about to get far more interesting.