If there is one technology that can give FDM stiff competition in additive manufacturing, it is carbon fiber. In recent years, there has been a huge influx into carbon fiber 3D printing, both on the manufacturing side and on the consumer side.

Carbon fiber 3D printers can produce parts and prototypes that are heavier in strength and lighter in weight compared to other 3D printing techniques. So, for those who value their strengths, we have put together a list of the best carbon fiber 3D printers. We primarily looked at the compatible filaments, to make sure you can print carbon fiber as well as other materials, such as nylon and more traditional ones like ABS, PLA, and TPU. We also checked crucial features like the build volume, printing speed, and overall ease of use, that all add value to the printer.

More features: double z-axis bed; 5-inch color touchscreen; Klipper firmware and CoreXY structure

The QIDI MAX3 3D Printer stands out as a top-tier option among carbon fiber 3D printers, boasting features that cater to both professional and enthusiast users. Its large build volume is a significant advantage, allowing for the creation of larger and more complex models without the need for piecing together parts. The dual extruder system is a standout feature, offering the flexibility to print with different materials, including specialized carbon fiber filaments. This feature is particularly beneficial for creating parts that require the strength and lightweight properties of carbon fiber. Additionally, the printer’s advanced cooling system ensures that heat is efficiently dissipated, maintaining a consistent print quality and reducing the risk of warping or other heat-related issues.

Comparatively, the QIDI MAX3 represents a substantial upgrade from its previous models. The increased build volume addresses the limitations of smaller printers, making it suitable for more ambitious projects. The addition of the second extruder opens up possibilities for multi-material printing, which was a constraint in earlier models. The improved cooling system is a thoughtful enhancement, particularly for those working with materials that are sensitive to temperature fluctuations.

More features: LayerLock Garolite heated print bed; LCD screen; Bondtech BMG Extruder with E3D V6 HotEnd

Our runner-up model is the Pulse XE NylonX. One of the best open frame machines for carbon fiber printing, the Pulse XE was developed to be used with carbon fiber and nylon materials. It is the first printer to be made for nylon filament. However, it also works with many types of filaments which include carbon fiber.

Like we expect from a carbon fiber printer, the nozzle of this machine is constructed from hardened steel. The hotend can therefore reach temperature of up to 300 degrees celcius which is why the machine is ideal for printing hard filaments. The structure of the hotend allows micro carbon fiber filled spools to be pump out easily, which is usually a challenge with other printers.

The Pulse XE NylonX printer has a print bed designed with special resins so as to ensure better adhesion when printing with nylon. For the right results, the machine’s print bed is also heated. This means you won’t be dealing with bed adhesion problems.

More features: Klipper firmware and CoreXY structure, two sets of nozzle for different materials, independent chamber heating system

The R QIDI TECHNOLOGY X-PLUS3 3D Printer is a formidable contender in the realm of carbon fiber 3D printing. It offers a substantial build area that is versatile for various projects, from intricate prototypes to functional parts. The dual extrusion system is a key feature, enabling the printer to handle a wide range of materials, including advanced composites like carbon fiber. The fully enclosed build chamber is a significant advantage, especially when working with materials that require stable temperature conditions. This enclosure not only maintains a consistent printing environment but also enhances safety by containing any potential fumes. The printer’s high-resolution printing capability ensures that even the most detailed designs are rendered with precision, while its user-friendly interface and multiple connectivity options, including Wi-Fi, make it a convenient tool for any workspace.

When compared to its predecessor, the X-PLUS3 shows considerable advancements, particularly in its user interface and overall usability. The enclosed chamber is a major upgrade, providing better temperature control, which is crucial for printing with materials like carbon fiber that are sensitive to environmental conditions. The enhanced user interface makes the printer more accessible, especially for those who may be transitioning from the brand’s earlier models. These improvements make the X-PLUS3 a more versatile and user-friendly printer, suitable for a wide range of applications.

More features: innovative Print Core system; 4.7-inch color touch display; dual-geared feeder reinforced for composite materials

Despite coming to the market with its first printer in 2011, the Dutch manufacturer, Ultimaker has become popular with the additive manufacturing community for offering open source solutions to its users. The S5 carbon fiber 3D printer has a printing volume of 330mm x 240mm 300 mm. The Ultimaker S5 is easy to use and a very intuitive painter.

Speaking of the functionality of the printer, it can be printed with both carbon fiber filaments and others. The maximum nozzle temperature that can be reached on this printer is 280 degrees Celsius. If you compare this to other printers on the list, where it lags could be the lower print head temperature. However, due to the other features it has, it is much better than most of its competitors.

The Ultimaker S5 has dual extruders. The machine comes with a removable glass print bed for general use. And for advanced engineering materials, the user can use an ultra-flat anodized bed made of aluminum. Ultimaker S5 has a color touch screen to operate the various print settings. The printer has a built-in filament flow sensor to monitor the flow after the printing process has started. Ultimaker S5 is used in the manufacture of complex parts in various industries, such as aerospace, jewelry, and dentistry.

More features: 2 extruders for different filaments; new automatic intelligent leveling mode; HEPA air filter system

The Qidi Tech X-CF Pro 3D printer is a machine developed to print with more classic materials (PLA, ABS, TPU, PETG) but above all with more demanding materials such as carbon fiber, PA12-CF, Nylon, polycarbonate, and more. Known for their easy-to-use closed box printers, Qidi offers a model here that is more geared towards professionals who need to print with materials that are impossible to manage with the other products in their FDM range. The “Pro” designation of the X-CF Pro model confirms this.

The Qidi X-CF Pro prints at the maximum volume of 300 x 250 x 300 mm with a layer height to be set from 50 to 200 microns. The recommended print speed is 60mm/s. A single nozzle printer, two extruders come with the Qidi Tech X-CF Pro, one of which can reach the temperature of 350°C, essential for using demanding materials such as carbon fiber, nylon, or PA12. The closed and filtered printing chamber maintains the ambient temperature for successful prints.

The Qidi Tech X-CF Pro printer also includes a BLTouch for automatic bed leveling with 20 control points. This steel heating plate is topped with a magnetic and flexible PEI to easily take off objects.

The in-house QidiPrint slicer is compatible with the XCF Pro, but those accustomed to additive manufacturing can also prepare gcode files using Cura or Simplify3D. The 5-inch front screen displays a clear and easy-to-use interface, while the printer can also connect to the network via Ethernet cable or Wi-Fi.

More features: Intelligent-assisted bed leveling; HD camera monitoring; 5-inch color touchscreen; improved air filtration

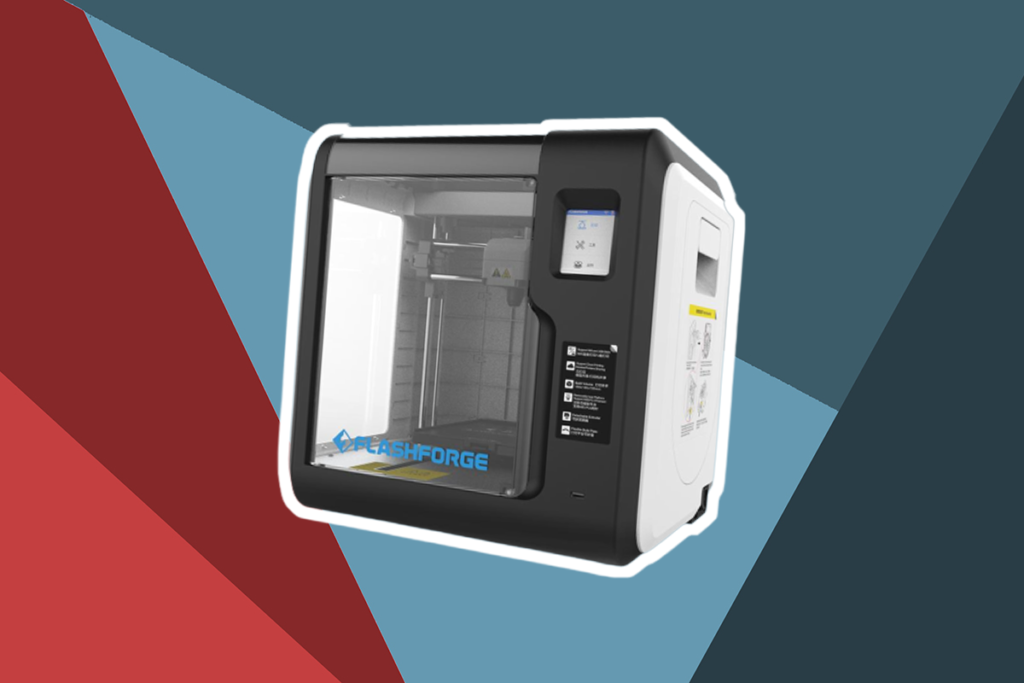

The Flashforge Guider 2 S comes with a high-temperature extruder that is capable of 300 ℃. So now you can print even more materials. The Guider 2 S is a desktop 3D printer with industrial production quality. It has a very large build volume and at the same time very high resolution and accuracy. The robust construction and construction ensure maximum stability and sturdiness when 3D printing projects.

The Flashforge Guider II S 3D printer looks incomparable with the Guider IIS V2. Like the Guider II S V2, the 2S has an integrated HD camera. This lets you remotely monitor the 3D printer. It’s compatible with materials such as PLA, ABS, Elastic filament, TPU, TPE, Carbon fiber filament, and more.

All you need is an internet connection. You can also connect and manage multiple devices at the same time. Cut your CAD models, queue up your 3D printing jobs and use the built-in webcam to check if 3D printing is working properly!

More features: single/dual extruder; 7-inch touchscreen; 0.2mm to 1mm nozzle diameters available

For private users, there are often affordable 3D printers starting for less than $1000, which already does a lot. However, more and more inexpensive devices are also being developed for small companies, such as the products from Raise3D. With the new Raise3D Pro 2 and Pro 2 Plus printers, the manufacturer has succeeded in improving on the predecessor named Rise3D. Existing functions from the N2 series have been adopted, improved, and supplemented. The extruder however is almost 50 percent faster than that of the N2.

The professional N2 series inspired the developers of the Raise3D Pro2 to some ideas. The professional 3D printer has a build volume of 305 x 30t x 605 mm, wireless connectivity, and a 7-inch full-color touchscreen. There are pressure recovery and dual extrusion capabilities. The extruder has a single or double gear option to choose from. The double extruder brings about increased filament adhesion and more reliable material extrusion.

Thanks to a magnetically exchangeable print bed system, the printing plate can be changed seamlessly. The motherboard with the ARM Cortex M7 32-bit controller ensures that the printing accuracy is maintained while the nozzle runs at higher speeds.

More features: single/dual extruder; 2nd generation dual Z-axis structure; fully industrial-grade structure

The basic concept of the Qidi printer is a stable frame made of sheet steel covered with plastic shells. With the iFast, all axes run on linear rails. The electronics are more or less separated in a separate compartment. With the iFast, we find 2 power supply units (bed separate) under the floor and then the electronics compartment behind the right housing cover.

The heating bed is a pleasingly flat, 8mm thick aluminum plate with embedded magnets, which holds the Magnet-Flex pressure plate securely in position as a pressure pad. The Qidi is also audible on standby. The 24V 40mm fan installed to ventilate the electronics compartment is not quiet and is a constant runner, but it would be very easy to replace it. We’re not entirely convinced of the fan’s usefulness anyway, it blows hot air from under the hood over the stepper drivers to the floor.

Through the air holes, you can see the “board heater” that is common with Qidi, the 8mm aluminum plate is then on top of it, and the magnetic flex plate is on top. This is not different from the X-Max / X-Plus, except for the size and the screws are a bit nicer.

The iFast is primarily advertised for its speed. It’s said that this model is 20% faster than the previous ones. It’s not sluggish for a printer of its size, but we don’t want to agree with the advertised 150mm/s. We see a maximum of 100mm/s here and, depending on the extrusion quantity in mm³/s, a little below that.

More features: Onyx and high-strength high-temperature fiberglass construction; unibody aluminum chassis and precision-machined components

Known for its ability to print with two of the most eccentric materials, namely high-temperature fiberglass and Kevlar, the Mark 2 is a premium carbon fiber 3D printer. Mark 2’s specialty is producing end pieces with high strength and versatility through the use of a continuous carbon fiber reinforcement process.

The printer has a build volume of 320mm x 132mm x 154mm and is capable of achieving 100-micron layer resolution. Markforged has developed its software under the name Eiger. This software allows users to import and cut a design optimized for the production of heavy-duty parts and prototypes. Mark 2 is an industrial-grade printer that can be used for mass production.

It should be noted that in addition to the composite materials and eccentric materials mentioned above, the Mark 2 also allows users to print with another rare material. This material is called Onyx, which is a nylon-based material that is 1.4 times stronger and stiffer than ABS. The manufacturer of this 3D printer has titled this printer a “reliability workhorse”, due to its ability to print continuously from the start of the day to the end.

It is rare to find an industrial-grade 3D printer in the price range like the Mark 2. Other printers that are available in this price range do not offer variability in print materials or print volume. So if you’re a hobbyist looking for a future in additive manufacturing based on carbon fiber 3D printing technology, the Mark 2 should be your go-to.

More features: dual extruder; 5-inch color touchscreen; smart spool monitoring through RFID sensors; built-in camera

The MakerBot Method 3D printer is the model unveiled at the end of 2018 by the American manufacturer. The machine was created for professionals, it takes over from the MakerBot Replicator by improving performance and functionality. Its print volume is not the widest (190 x 190 x 196 mm) but its precision starts at 20 microns (up to 400) and the head movement speed can reach 500 mm / second. The printing speed is up to twice that of other professional 3D printers, not to mention its standard dual extruder. The dual extrusion working volume drops to 152 x 190 x 196 mm, still maintaining layer resolution between 20 and 400 microns.

The MakerBot Method is a closed 3D printer with a temperature-regulated printing chamber for always perfect prints, regardless of external conditions (ambient temperature, dust, etc.). Filament detectors will be able to manage the spool change, not to mention all the other sensors installed in the Method (a total of 21 sensors). The filaments accepted by the Method are all proprietary: MakerBot PLA, MakerBot Tough, MakerBot PVA, and MakerBot PETG, knowing that other materials will expand this palette. The colors are currently fairly standard: grey, black, white, orange, red, and translucent in PETG. These reels will take place in a closed compartment under the machine.

The 5-inch color touch screen is of high quality and displays a high resolution, quite different from the small LCDs on board low-cost printers. The MakerBot method is simple: the calibration is automatic for the nozzle, the Z-axis, and the loading of the filaments. The connection is vast to suit all uses: Ethernet, WiFi, a USB port for linking to a Windows / Mac computer, and a slot for a USB key. The base warranty covers one year, but MakerCare Gold and Platinum plans can extend that to two and three years, respectively.

In this guide, you’ll find out everything about printing carbon fiber in a 3D machine as well as how to choose this type of machine.

Carbon fiber is currently one of the most popular and common materials for the manufacture of 3D printed objects thanks to the characteristics of this material. Its strength, versatility, and lightweight make it one of the best materials for prototyping 3D parts.

We can say that carbon fiber is made up of a long chain of carbon atoms linked together. This chain usually has a diameter between 5 and 10 micrometers and its length varies depending on the application that is going to be given to it.

Carbon fiber in its pure state is 5x stronger than steel. Also, it is twice as stiff, yet considerably lighter. The whole set of characteristics and properties of carbon fiber makes it a very suitable material for applications that depend exclusively on the material and optimizing its performance. This occurs, above all, in sectors such as aerospace, automotive, military, or civil engineering, among others.

Chopped carbon fibers are widely used in compression and injection molding applications. Chopped fibers are used in making machine parts and gears that are prone to tear and wear.

As for continuous composites, these fibers are far stronger than their weight. They have incomparable durability when compared with thermoplastics. These can be used in making parts that are as strong as 6061-T6 Aluminum.

As you may have already understood, the printer is the best for creating high-strength materials. In addition, the parts produced are lighter in total weight.

It is for these reasons that composite materials are ideal for a wide range of 3D printing applications.

Whether it’s functional prototypes or tool accessories, auto parts, aircraft, or R/C vehicle parts, carbon fiber 3D printers can produce them all.

To be able to print with carbon fiber, your printer must have:

3D printers make it possible to implement your creative ideas right from the comfort of your own home: spare parts, toys, or household utensils – almost anything is possible with the right device. But with carbon fiber models, you’re heading towards the industrial field. But what should you consider before buying a 3D printer for this application?

The first 3D printing methods, such as stereolithography (SLA), emerged in the 1980s. This method is still used today in many 3D printers and works as follows: The object is made of light-curing plastic, with a laser hardening the desired surface layer by layer, thus enabling precise printing. After the print is finished, the object needs to be cleaned and irradiated with UV light.

The Fused Deposition Modeling (FDM) printing technology is increasingly used in printers for home use and is significantly cheaper than stereolithography. The plastic is heated, melted, and then fed out of the extruder so that the object can be built up from layers that melt together – after cooling, the three-dimensional object is finished.

In addition to this widespread printing technique, there are also 3D printing methods such as laser sintering, 3D screen printing, or laser beam melting.

The print volume or build volume determines the maximum size of the three-dimensional object – projects that are too large are not possible due to the limited print area. With SLA technology, the resin is placed in the limited container before printing, the print volume can be 4 liters to 2 liters depending on the model. In addition, the width/depth of the objects is around 15 centimeters and the height is under 20 centimeters. With FDM technology, even compact models offer up to 20 centimeters of space in all directions and larger models up to 30 centimeters. FDM printers draw filament from spools, which typically hold 500 to 1,000 grams.

Different 3D printer models differ greatly in terms of printing speed. High-quality printers in the carbon fiber printing world can operate at up to 600 millimeters per second. The QIDI MAX3 3D Printer can print up to 600 mm/s while the R QIDI Technology i-Fast can print close to 150 mm/s.

Meanwhile, relatively inexpensive printers can achieve less. Since the application is mostly industrial, speed should play a major role in most cases. The best quality prints are done at a slower speed than is required with PLA and ABS printing. However, if you expect a certain printing speed, you have to set a larger budget.

The design of the printer is also a major requirement. There are open-frame and closed-frame printers. There is a single and dual extruder feeder system. The best direct drive 3D printers usually have single printers. However, dual extruders are ideal for printing different filaments. You should also choose a model with an automatic intelligent leveling mode such as the R QIDI Technology X-CF Pro. Some machines do have a high-strength and high-temperature construction, sometimes made of fiberglass and a strong aluminum chassis with precision-machined components.

The filaments used by the carbon fiber 3D printer consist of segments less than a millimeter in length, which are mixed with a thermoplastic generally known as the base material. There are different types of filaments that can be purchased and that are filled with carbon fiber, such as PLA, Nylon, ABS, and polycarbonate.

These fibers are characterized by being excessively strong, which causes the filament to increase both its strength and stiffness while reducing its overall weight.

Some of the requirements of the carbon fiber 3D printer should be similar to those stated in the case of the base material to which the carbon fibers were added. The main difference that we can observe is that the fibers can clog the nozzles of 3D printers, therefore it is highly recommended to use hardened steel nozzles to avoid this.

Also, above a certain fiber threshold, the 3D printed part will lose its surface finish. Recently, different companies have developed carbon fiber filaments for somewhat more technical applications. These filaments are used as a base material for high-performance polymers, such as PEEK or PEKK.

This model offers both the benefits of carbon fiber, such as durability and strong chemical and mechanical performance, as well as a good strength-to-weight ratio.

3D printers have special software to create printable path files from 3D models. Depending on the manufacturer and model, this software can be different – what is important for you is:

Pay attention to the compatibility with your operating system (Windows, Linux, Mac), because not all software is available for every system.

A 3D printer is controlled by 3D printer software that is installed on your PC or laptop, for example. When buying, make sure that you can easily connect your computer to the printer and use it directly.

Some printer models can even be controlled via WiFi, which makes the application even more convenient and the laying of cables unnecessary. If the WLAN connection is not working properly at the moment, a USB connection should still be possible as an alternative. An SD card connection is also available on some printer models.

The durability of the machine should be reassured. Carbon fiber printing machines are quite exposed to wear and tears so the nozzle, print bed, and frame must be high-strength and high-temperature resistant. Most models often come with one year of warranty. In our review, most of the 3D printers have one year warranty, from the QIDI MAX3 3D Printer to the MakerBot Method. You may not find something better but that should be sufficient.

A carbon fiber 3D printer is rarely a one-time investment. In addition to continually purchasing materials to print items with, there are maintenance costs on the perishable parts of the printer, such as the nozzles on an FDM printer. Of course, parts can wear out or break too, which means sourcing replacement parts is a sensible consideration if you plan to print in the long run. However, the price range of a carbon fiber 3D printer is usually between $700 to as high as $15,000, depending on the application.

Now that you know what the features to consider are and what the best 3D printers for carbon fiber printing are, it will be easier for you to decide. You can decide based on the application of functional parts and prototypes that are produced with these printers.

Rated 9.9/10, the QIDI MAX3 3D Printer is our Editor’s Choice. It’s an FDM printer that can print materials such as carbon fiber, nylon, PLA, TPU, ABS, PC, and more.

The Pulse XE NylonX is the best for those looking for an open frame model for carbon fiber printing. With a rating of 9.6, the Pulse XE was specially developed to be perfectly compatible with nylon and carbon fiber filaments.

Also rated 9.6, the QIDI TEC X-Plus3 is one of the best carbon fiber 3D printers with the best value for money in the selection. The printer was not only specially developed for printing carbon fiber and nylon. It can also be used with many other filaments such as PC, PLA, ABS, PETG, and TPU.