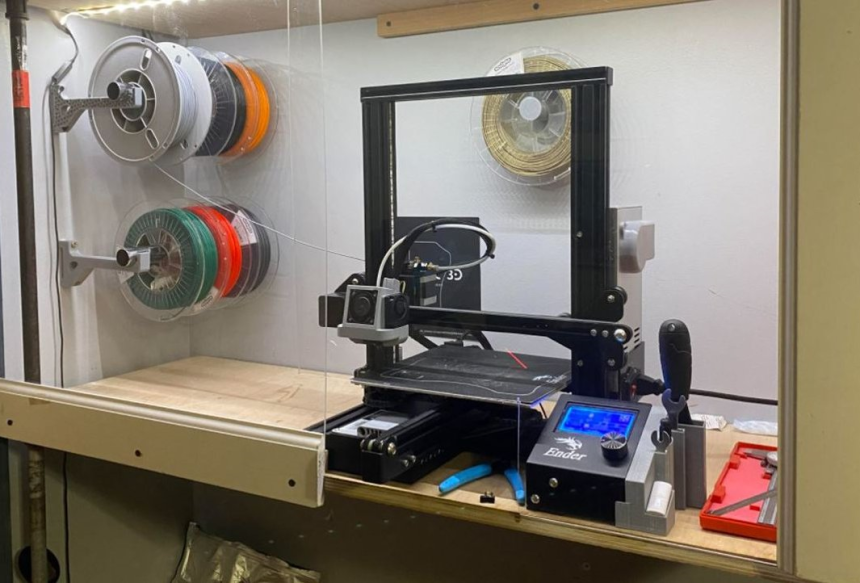

The era of 3D printing is well and truly here, and people are starting to capitalize on it. The popularity of this venture or practice is further boosted by the design and release of cheaper 3D printers, some of which make up the Ender 3 line (including the Ender 3 V2) by Creality.

Though there are a couple of 3D printers under this line, our focus isn’t on any single individual printer but rather on one factor that’s important in all of them; the Ender 3 Print speed. The importance of print speed cannot be emphasized because of what use is a 3D printer if you spend hours waiting on models?

Sure, there are many other factors (such as the level of detail of models and filament used) that could affect the overall time that would be taken to print out a model, but the machine is a critical part of the overall speed equation.

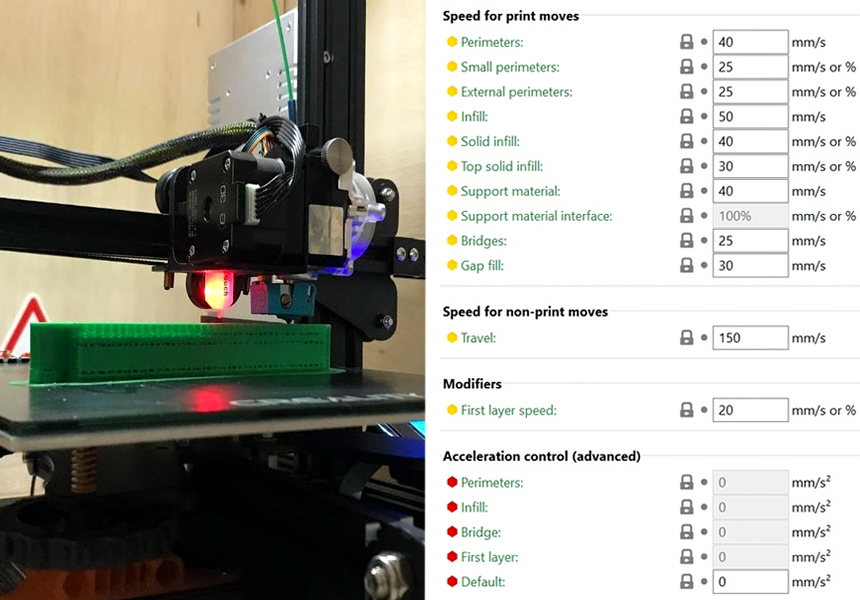

If we are to believe the manufacturers of the Creality Ender 3 Pro, which we should because they are the height of expertise in their space, the fastest possible print speed is about 200mm/s. In summary, the Ender 3 Pro can print fast, but you shouldn’t be doing so. Below is a quick run-through of the most appropriate printing speeds for every filament.

Most people always get started printing with PLA; it’s popular that way. For the complete newbies, “PLA” stands for Polylactic acid, and it’s popular because it’s easy to print with and mistakes made while printing with it are not as damaging. As regards printing speed, 60mm/s should be okay on this filament.

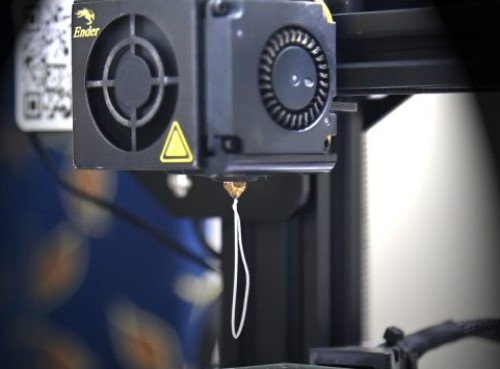

TPU stands for Thermoplastic Polyurethanes Trusted Source Thermoplastic Polyurethane (TPU) Material: Properties & Applications TPU provides a large number of physical and chemical property combinations for the most demanding applications such as automotive, wires and cables, breathable films for leisure, sports and textile coatings, weatherable, non-yellowing films etc. omnexus.specialchem.com , and it is popularly used for models that are intended to be flexible. Unfortunately, except you are using 3D printers especially suitable for working with TPU, its nature may also contribute to the slower printing speed you would have to endure when working it. At optimum speed, you should be able to print as fast as 40 mm/s, but slower (around 20mm/s) may be better most times.

PETG means Polyethylene terephthalate glycol Trusted Source What is PETG? (Everything You Need To Know) - TWI Polyethylene terephthalate glycol, known as PETG or PET-G, is a thermoplastic polyester that delivers significant chemical resistance, durability, and formability for manufacturing. www.twi-global.com , but it is more commonly referred to as glycolic polyester in reference to how it is made from polyester, Polyethylene terephthalate. The material is used in the printing of models that are required to be moderately heat resistant, chemical resistant, and durable.

The nature of the material means it can get stringy, especially when you print too fast. As such, sticking to speeds between 60 mm/s and 20 mm/s should provide the best results.

In what represents one of the relative disadvantages of the Ender 3 printers, they can be used for pure metal. Though they can deal with metal-infused PLA, it’s not the same thing. This limitation is to be expected considering that these printers are more or less entry-level 3D printers. However, if you are to be using a metal-infused PLA filament, the ideal printing speed shouldn’t be too different from that of the PLA.

As earlier stated, other factors could affect the overall printing speed beyond the machine itself. The most straightforward of these factors is the type of filament used with the Ender 3, but we have touched on that already. Other factors to consider include:

Regardless of what speed the printer is set to, the size of the model you’re printing would affect the length of the process. The same goes for the level of detail that the model is expected to possess.

A print of a spoon would take you significantly less time to build than that of a miniature house, provided every other factor stays the same.

We’ve spoken about the 3D printer in terms of its speed, but there are other quirks (or limitations, if you may) common to individual 3D printers that could also affect its speed. One of such quirks in the Ender 3 Printers is the difficulty in maintaining a level bed.

This difficulty arises because of the absence of an auto-leveling feature in these printers. If the bed starts shaking while the printer is still printing, you might need to stop or slow down your printing. The alternative is risking the quality of the model you would get. Alterations in the bed size for an Ender 3 printer could be explored to help with this problem as well.

It should be noted that if you are going to be changing 3D printers, you might need to look up how to level the bed again. For instance, both the Ender 3 Pro and Ender 3 V2 are relatively more stable in this regard, but the procedures for leveling the beds in both are slightly different.

Things such as this shouldn’t be judged by numbers because higher isn’t always better, but in this case, 5 is faster and better than 3. The max speed of Ender 5 3D printers is the same as that of the Ender 3s, but the realistic speeds are about 20 mm/s apart, with the Ender 5s having the advantage. That said, you can realistically print at 80 mm/s using an Ender 5 printer without risking the integrity of the model.

There are different variations of the Ender 5 3D printers around, but a good range of printing speed to consider when using any of them would be 60 – 80 mm/s.

3D printing is an activity flexible enough to dispose of many of the conventional barriers to building stuff. However, the versatility of the process brings with it different obstacles more peculiar to it. You can skip the whining and simply learn how to move past them, though.

For example, a lack of knowledge regarding ideal Ender 3 print speeds may be the source of some of the problems you have faced up until now. Now, you are equipped with the knowledge to use the printer more efficiently with different types of filaments. Let that be a guiding lesson as you keep experimenting on your 3D printer; take note of the specific quirks of your printer, and when you’re at an impasse, whine less and research more. Adios!