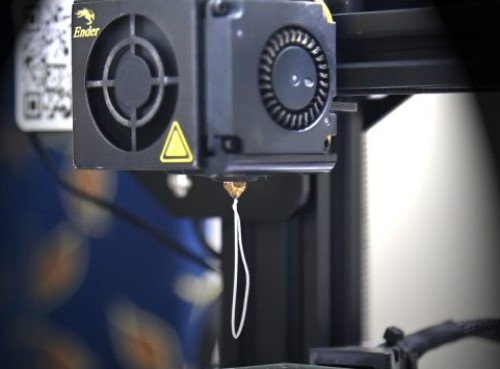

We’ve all been there; you leave your print job running. Everything seems to be working properly, so you go to the next room for a short while. When you come back, something seems to be wrong, and your printer is under extruding. There are other times when you start printing only to be disrupted by a clicking sound from the extruder area. It’s annoying and frustrating!

Extruder clicking is common in 3D printers. Most people assume that it’s caused by a defect in the extruder, while in reality, it’s usually an indication of other underlying problems. There are several articles on extruder clicking, but few on how to solve the problem, which is why we have compiled a comprehensive guide for you!

Extruder skipping occurs when your 3D printer fails to supply the required material to correctly print a layer. Even though there are various reasons why this happens, the good news is that once you know what to look for, you can easily solve the problems.

Here are the top causes of extruder skipping.

The most common indicator of low temperatures is extrusion clicking after the first layers. This clicking sound is usually caused by the printer trying to advance your filament.

In some instances, the low temperatures are caused by the thermistor being far away. This component is responsible for reading the hotend’s temperature, and if it’s off, it could cause a wrong reading by up to 10 degrees celsius.

If the hot end is the problem, you should replace it altogether, and based on popular reviews; the E3D Prusa MK3 is one of the best solutions. It can fit both the MK3S and the MK3 and is more reliable than other alternatives. This hot end kit comes with a thermistor & Prusa heatbreak and has a maximum temperature of 285 degrees celsius. It’s also easy to assemble and works immediately after installation.

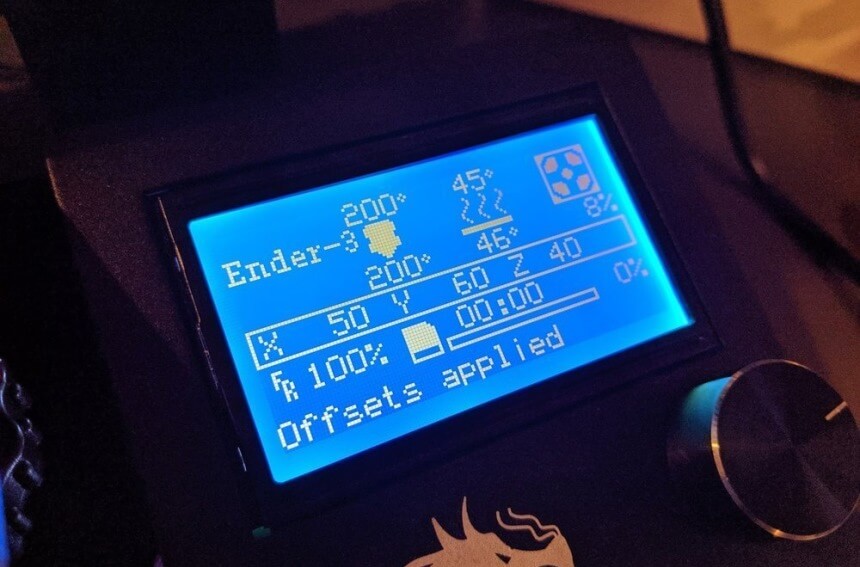

Confirm that you have set your printer to the recommended temperature range based on the material you’re using. It’s, however, important to note that heated thermostats are often inaccurate so if the problem persists, try lowering or raising the temperature slightly to see if the skipping stops. You should also try reducing the feed rate.

For wrong thermistor readings, you should gradually increase your temperatures and check for any filament residue. If print material comes out, you should set the printer to the correct temperature to stop the Prusa mk3 extruder clicking.

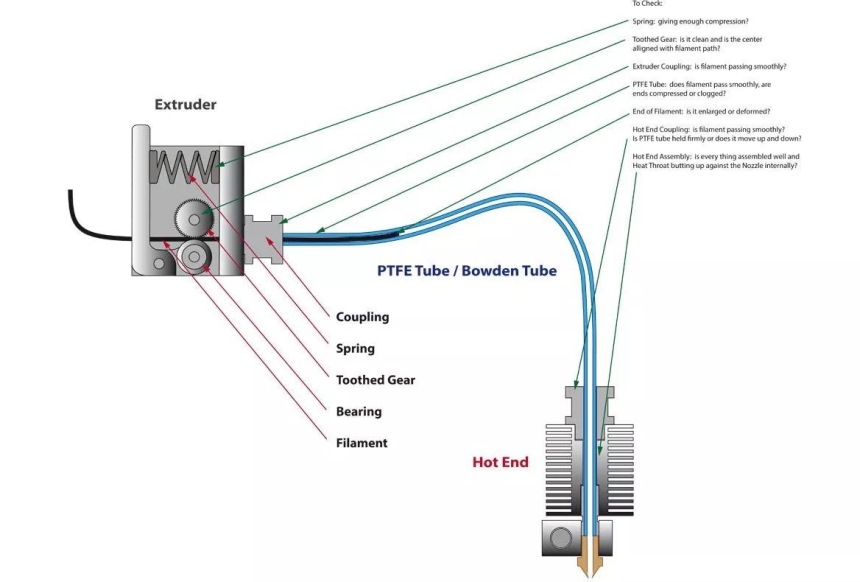

Nozzle blockages are sometimes caused by a thermal break between the heat sink and the heat block. This allows the heat to get to the heat sink, which can cause the deformation of the printing material. The material then forms small plugs in the areas with lower temperatures, causing blockages.

There are also instances where the printer has cooling problems. If this is the case, the print material cools too fast and wraps around your nozzle. This then prevents the filament from coming out.

You can easily remove the debris or blockages using a cleaning needle. If this doesn’t work, you should get a new nozzle. They are easy to get and are relatively affordable. If the blockage is caused by a thermal break, you should fix your heat sink or lower your temperatures.

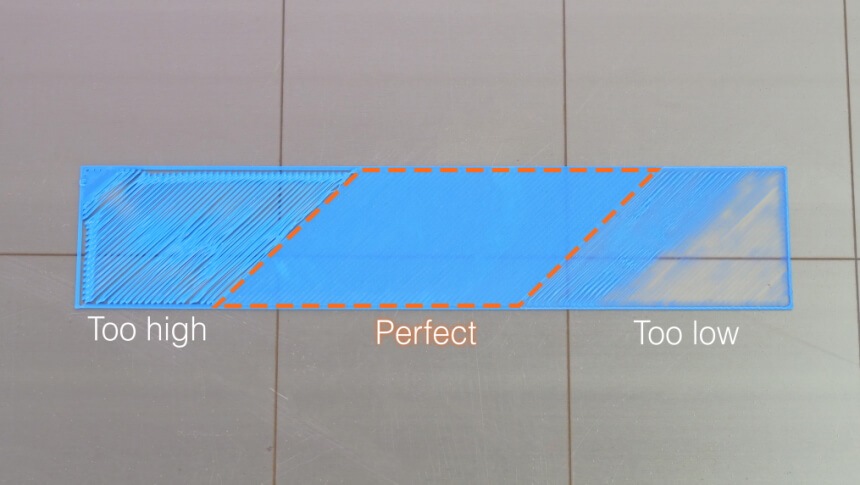

If you can slide a normal printing paper underneath the nozzle with slight resistance, then the printer is fine. If you face too much resistance, then the nozzle is too tight, while no resistance means it’s too loose.

The best way to solve this is by leveling your 3D printer properly. Make sure all 4 corners and the center are leveled close to their previous position. We recommend that you preheat the printer bed before leveling it to prevent it from wrapping and run tests to confirm that the nozzle is in the right position.

Make sure that the power accessories are fully functional and that the cables aren’t damaged. They should have the proper voltage for your printer and have well-fitted connections. If this is the root of the clicking, get a new dual-extruder, better power supply, or suitable cables.

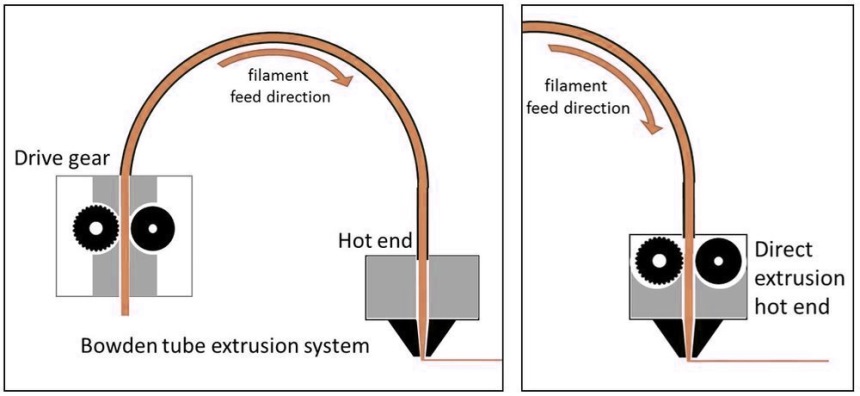

If the friction is excess, it prevents the stepper motor from successfully pushing the filament, causing slippage in the extruder motor.

Push the filament manually through the PTFE tube to check for blockages. If it experiences friction, you should clean out the debris, and if this doesn’t work, you should get a new Bowden tube. It’s advisable to clean the PTFE tube at least once every week.

Reduce your printing speeds to about 35mm/s and then gradually increase it by 5mm/s. This is most effective if your printer was working properly in simple angles but is unable to extrude properly when going at angles.

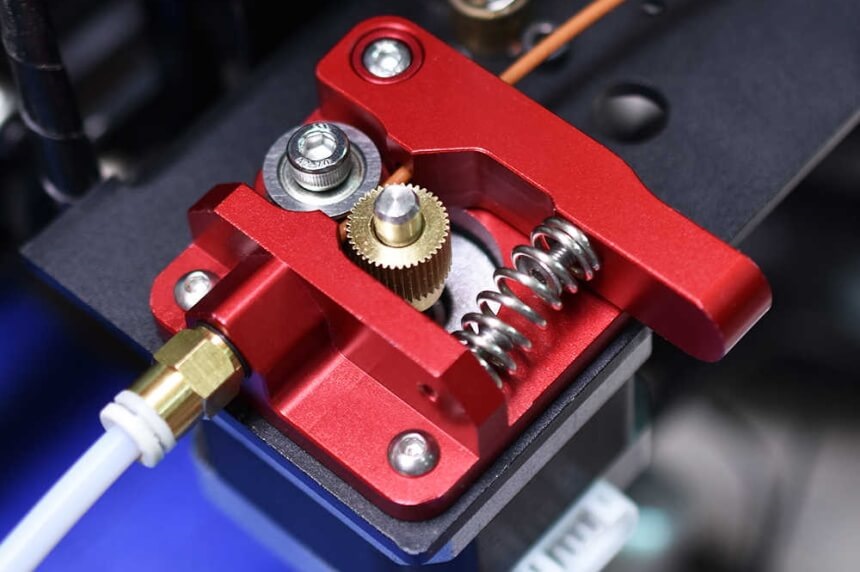

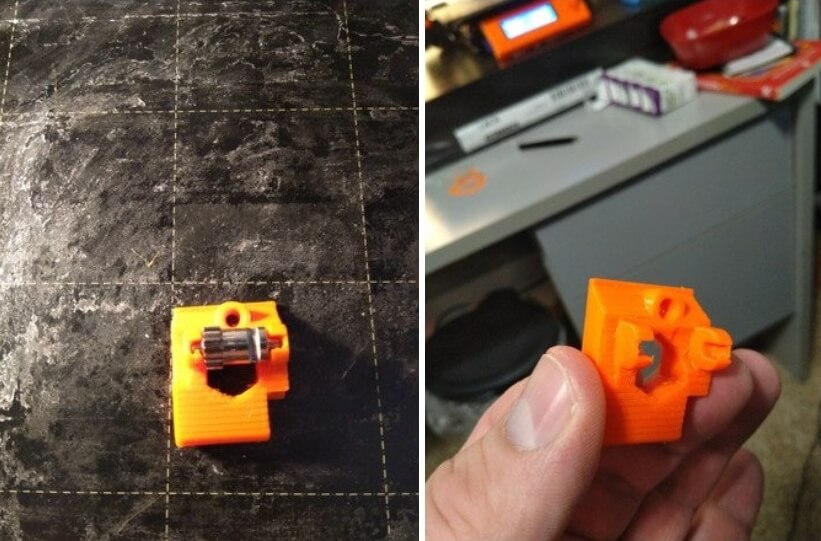

For example, in some printers, if the gear teeth are the filament feeder’s clipping part, they could get damaged when working on metal components. In some instances, although rare, it could be that the idler bearing has become worn out.

There are also printers whose stepper motors generate too much heat, which gets transferred to the extruder gear and finally the filament.

Realign your gear until you can easily pull the filament through the feeder. In case of worn-out idler bearings, get a replacement, and if there’s debris stuck between the gear teeth, make sure you clean it out.

If the stepper motor’s temperatures are too high, get a small fan for it or replace it with a better motor.

You should get an idle gear stabilizer that gets rid of the holes in the support preventing the axel from slipping around.

If the feeder tension is too high, the filament is grabbed with a high force which then flattens it and makes it difficult to pass through the Bowden tube. This then results in insufficient printing material being released.

Even though most filaments are 1.75mm in diameter, there are those that are 3mm. Confirm that you’re getting the correct filaments for your 3D printer. You should also check the tension settings to make sure the power connection is stable. Faulty connections cause the motor to run erratically and slows down the feed.

Get the correct power accessories for your printer and check that the cables have the correct voltage.

According to The Guardian Trusted Source Is 3D printing about to hit the mainstream? | 3D printing | The Guardian The technology for 3D printing is moving fast. One day every home may have one www.theguardian.com , there will come a time when every home will have a 3D printer. Here s how to fix extruder clicking in the most popular models.

According to most reviews, the Anet A8 is one of the most efficient 3D printer models. It comes in a DIY version with all the parts assembled and all ready for installation. This also makes it easy for you to troubleshoot the extruder clicking yourself.

The Anet A8 also comes in a sturdy metal frame construction, and its printing precision is very high. Its operation method is upgraded, and it has a convenient and efficient knob operation feature and an LCD display with an ergonomic design. The hotbed ensures smooth printing through a glass panel and a larger printing area.

If you experience filament leaks as you print, it means the printer nozzle is leaking, so confirm that it’s assembled correctly. If the parts start detaching from the heatbed, make sure you set it to the correct temperature to stop the anet a8 extruder clicking.

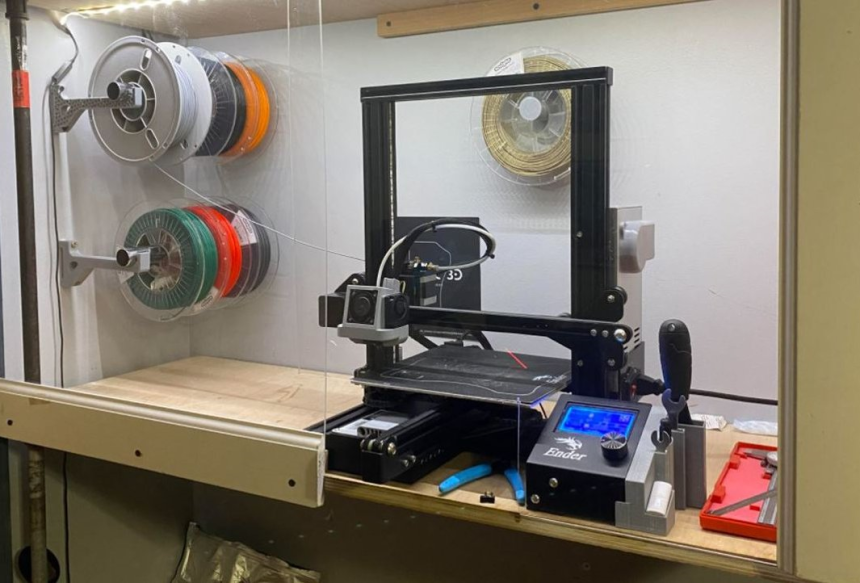

The Creality Ender 3 is one of Amazon’s bestsellers, and it’s not hard to see why. You can assemble it in around 2 hours, and it comes with a protected power supply that makes it easy for the heat bed to get to 100 degrees within 5 minutes.

This 3D printer can also resume its printing function even after power outages happen. It has advanced extruder technology that ensures smooth and noiseless printing.

If you experience any extruder skipping or ender 3 extruder clicking, troubleshoot to make sure it’s not any of the above problems. You may have to calibrate your printer, but once you do, you won’t experience any challenges.

According to Forbes Trusted Source The State Of 3D Printing, 2019 The study’s methodology is based on interviews with 1,300 respondents coming from Europe (64%), United States (16.6 %) and Asia (20.2%), which is the fastest growing region internationally today as measured by this survey over five years. www.forbes.com , 3D manufacturing companies are becoming heavily reliant on 3D printers. The Clicking sounds, however, make operating one highly frustrating, especially if you’re just starting out. This is further worsened if you experience gaps in your print. 3d printer extruder clicking is usually an indication of underlying problems with your printer, and we hope that the above guide helps you fix the problems.