3D printing technologies provide versatile solutions in a wide range of applications. High-resolution 3D printers are now more affordable, user-friendly, and dependable.

This means 3D printing technology is now more accessible to businesses, but choosing between competing for 3D printing solutions can be challenging. Stereolithography (SLA) and Selective Laser Sintering (SLS) are two common 3D printing methods created in the 1980s and have been utilized for decades.

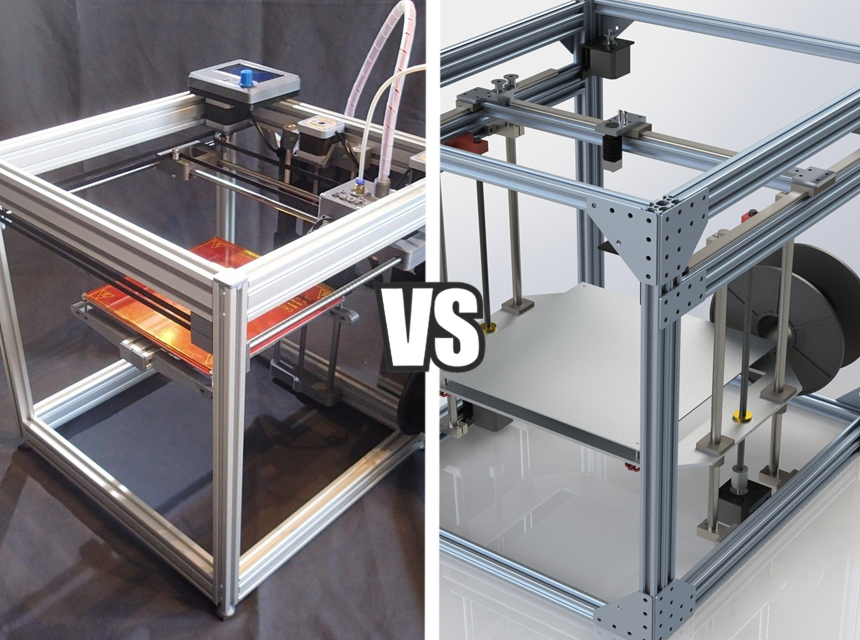

Today, we’ll break down both these 3D printing methods, compare SLA vs. SLS 3D printing, and highlight which option best suits your needs.

SLA, also known as stereolithography, is the most popular method of 3D printing Trusted Source Stereolithography (SLA) 3D Printing Guide Learn about the different stereolithography (SLA) 3D printers, materials, applications, and how SLA compares to other types of 3D printing technologies. formlabs.com . Chuck Hull invented this printing technique in 1986. Objects printed in this manner are made by shining an ultraviolet light beam into a resin vat.

When a layer is completely cured, the object is lowered to allow the next layer to get printed. Making a 3D print using SLA requires a supporting structure, which is typically generated by the printer’s CAD software.

SLA can be quite detailed, but it rarely produces functional parts. Also, because the plastic hardens when exposed to UV rays, objects printed with this method cannot be left in the sun as they will get brittle and eventually break.

Fortunately, the ANYCUBIC 3D Printer provides super quick printing to shave off some time.

As we briefly mentioned earlier, SLA Trusted Source Photopolymer - Wikipedia en.wikipedia.org is a 3D printing technique that employs a laser and resin. Stereolithography involves directing a laser at specific points in the resin vat to cure the resin to form a pattern.

The first 2D pattern is typically suspended from an upside-down chamber and becomes the first layer of the print. This chamber initially rests on the resin container’s surface and is gradually raised as more layers solidify.

Because most SLA printers use a UV laser and resin, setting up and post-printing can be difficult due to ambient UV light. Furthermore, the resin is toxic and can emit a hazardous vapor with a foul smell.

There are two ways to move the laser. The most common and efficient method is using a set of mirrors to move the laser around the print surface. Because the laser’s focal width is smaller than the nozzle sizes on FDM machines, SLA printers can print objects more precisely.

If you’re looking for the best resin 3D printers, check out our detailed guide.

The video below demonstrates how SLA 3D printing works.

Selective Laser Sintering Trusted Source Selective laser sintering - Wikipedia en.wikipedia.org (SLS) involves using a laser to heat powdered material until it solidifies. This printing method was developed in the mid-1980s by researchers at the University of Texas at Austin as part of a DARPA-sponsored project.

SLS produces a stronger end product Trusted Source Guide to Selective Laser Sintering (SLS) 3D Printing Learn about selective laser sintering (SLS) 3D printers and how SLS 3D printing works, including different materials, applications, and workflow. formlabs.com than SLA and is capable of making functional prototypes. However, the finished product is not very attractive. SLS has a rough surface finish that makes it unappealing to the eye.

For decades, SLS 3D printing has been a common choice among engineers and manufacturers. The technology’s cost-effectiveness and high productivity make it ideal for various applications ranging from rapid prototyping Trusted Source Rapid prototyping - Wikipedia en.wikipedia.org to custom manufacturing.

Furthermore, recent advances in materials, software, and machinery have made SLS printing more accessible to a larger range of businesses, allowing an increasing number of businesses to use this tech that was formerly limited to some manufacturing industries.

SLS is a more common 3D printing method in an industrial setting. The laser in an SLS printer melts and sinters powder together to form an item. Furthermore, the power of the laser in an SLS printer varies. SLS printers are frequently used to print metals, ceramics, and plastics.

However, the laser cannot create a solid bond in these materials. As a result, the finished item may require further processing in an oven to reach maximum strength. Moreover, SLS machines use powdered printing material, and a roller within the printer deposits new layers of powdered printing material on top of partly sintered ones.

Furthermore, the unused powdered material acts as support all through print, eliminating the need for printed supports. Therefore, users can create more complex structures. Another advantage of the SLS printing method is printing a much wider range of useful materials more precisely than other printing methods, leading to sturdier products.

Since 3D printers have many uses in manufacturing industries, professional architects usually find a use for them. So, check out our article on the best 3D printers for architects if you’re looking for the best printers for this purpose.

The video below shows how SLS 3D printing works.

So, what is the difference between SLS and SLA? While both printing methods share some similarities, we’ll highlight the differences between these techniques in this section.

Common applications for objects made using SLA include large objects, cosmetic designs with a smooth surface finish, and objects requiring intricate detailing.

Nevertheless, if durability is important, SLS is the better process. SLS quickly creates functional product parts and accurate designs. Also, there are no support structures needed with SLS 3D printing. As a result, allowing users to include various pieces into a single build, making it a cost-effective method.

Moreover, SLA materials are photopolymers, also known as liquid thermoset resins. SLA offers the most diverse range of 3D-printable plastics with various mechanical characteristics.

SLS printers are typically models that are large and use lots of power. Moreover, SLA printers are typically smaller and can be used as desktop machines. Also, while SLA is more convenient, SLS printing can create larger and smaller items faster than an SLA printer because SLS machines have a larger build area and do not require support structures.

Even though there aren’t predetermined resolutions for these printing technologies, there are limitations that result in each 3D printer offering a resolution and accuracy within a specific range.

Because of the materials used to manufacture their products, SLA 3D printers have a higher resolution than SLS printers; the ELEGOO 3D Printer is a great example.

SLS machines use polymer powders, producing a granular finish on the object. Although the process is precise, it does not provide the same level of detail as SLA printers. These printers produce a very smooth surface, allowing you to notice even the smallest detail.

One of the primary distinctions between SLS and SLA printing is the compatible materials. As previously stated, SLS makes use of polymers and resins. Some polymers like polystyrene and nylon can also be used in SLS. Moreover, metals and ceramics can also be used in SLS printing.

Furthermore, SLA printing employs liquid resin, which is toxic Trusted Source Health and safety hazards of 3D printing - Wikipedia en.wikipedia.org . Furthermore, liquid resins can get messy, which makes post-processing cleaning tedious. On the other hand, SLS printing involves using powder, which is far more manageable.

However, inhaling particulates, particularly those containing certain metals, can be hazardous to your health. Moreover, depending on the materials you use, you’ll need to consider ventilation in your workspace.

At first glance, this is one of the most noticeable differences. The sintering process creates a porous solid material when using an SLS printer. This is because the air initially inside the powder creates microscopic air bubbles on the sintered object.

Even though the texture isn’t immediately visible, it feels slightly rough when touched. Alternatively, polymerizing liquid results in a material with a smoother surface texture.

For raw material options, polyamide powder comes in two basic colors: black and white. A third option could be gray by combining those two, but the selection is limited, with no transparent SLS prints available. On the other hand, resins printed with SLA machines provide additional options when mixed with colorants.

SLA and SLS both involve post-processing. SLA parts have to be cleaned to remove uncured resin, then post-cured, and supports also have to be removed. With SLS, the excess powder must be cleaned off. SLA and SLS can be finished with a machine and painted to obtain an excellent surface finish and remove excess layers.

Because SLA final products are smoother and shinier, polishing is usually unnecessary. However, for SLS prints, polishing can be needed if a smoother, shinier appearance is required.

Abrasion resistance in 3D printing refers to a material’s ability to withstand damage from frequent contact during use. When a part is worn, it gradually loses its surface, resulting in deformation. Because of the engineering-grade materials used and the thermoplastics being sintered, SLS 3D printers generally produce more durable, abrasion-resistant parts.

Another difference between SLA and SLS printers is the price. SLA printers are available for under $500, whereas SLS machines typically cost way more. Moreover, the overall cost of both printers increases over time, as the printing materials can be expensive. For instance, resins are expensive, whereas some SLS printing materials like nylon are relatively inexpensive.

If you’re looking for relatively affordable high-end 3D printers, check out the best 3D printers under $1000.

The answer to SLA vs. SLS 3D printing entirely depends on your project’s requirements and how much money you are willing to spend on a 3D printer.

SLA is the better option if you have a limited budget and require high-resolution models but do not require mechanical flexibility. On the other hand, if you’re a professional with a bigger budget who needs to print working models precisely with high-end materials, SLS is the best option.

However, we would recommend choosing SLS printers if we were to pick. First, preparing the printer for work and cleaning up the excess powder takes far less time and effort. Furthermore, SLS printing also creates the most precise products right away, and it supports printing multiple parts at once.

SLS is a better choice whether you need to create many simple designs or more complex designs. Moreover, SLS printers don’t require support structures. Also, there is no need to put parts together after they come out of the printer.

Both SLA and SLS are effective 3D printing techniques with their respective pros and cons. SLA offers superior detail and smoother surface quality, whereas SLS is ideal for creating mechanical parts that don’t require too much detail.

Consider these characteristics when deciding on your preferred option. Hopefully, we’ve answered the pressing SLA vs. SLS question you had earlier in the article. Moreover, consider buying both 3D printers to get the best of both worlds if you can afford to.