Have you heard of ABS 3D printers? Did you know they could print just about anything your heart desires? There are a lot of different features that go into ABS 3D printers. The printing technology is how the printer works. The accuracy and definition are how close the printed object is to the CAD design that it was based on.

ABS is a very versatile material, but you may want a printer that can use a plethora of materials so you can experiment. Lastly, if you are going to be using your printer for hours or even days at a time, you will want to consider how much power it uses because it will affect your electric bill. Based on these, the ANYCUBIC 4Max Pro 2.0 is our Editor’s Choice.

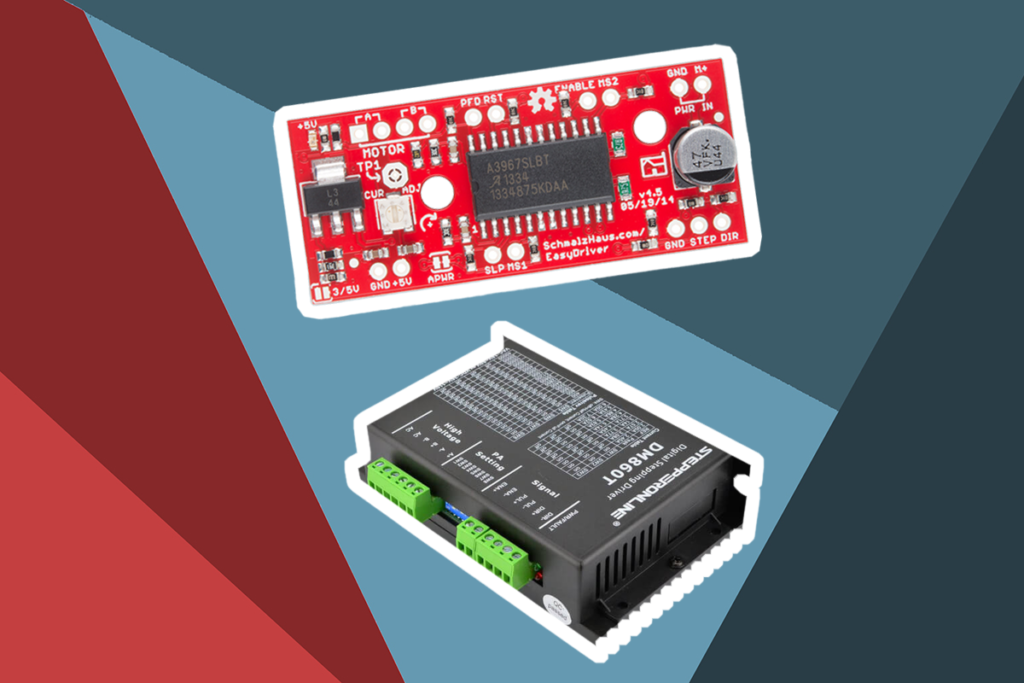

More features: upgraded leveling knobs, upgraded fan, integrated sheet metal structure, stepper drivers

This printer is high quality with a responsive touch screen. The auto power shut-off saves power and is also a safety feature. The sensor pauses if your filament runs out. It has a very high print speed and accepts many materials. It is upgraded from the previous model with a new fan and leveling knobs.

We were impressed with the upgrades this printer has made from its previous model! The fan, which is a vital part of any printer, has undergone a balance correction that is dynam which betters the stability of printing. The leveling knobs are also upgraded for an easier experience and less effort of 60% compared to typical leveling.

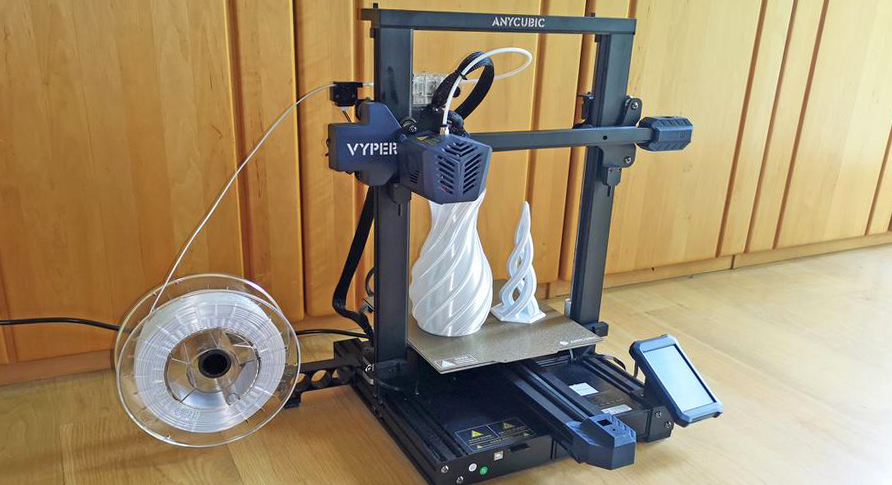

More features: auto-leveling, large size touch screen, stepper drivers, fast assembly

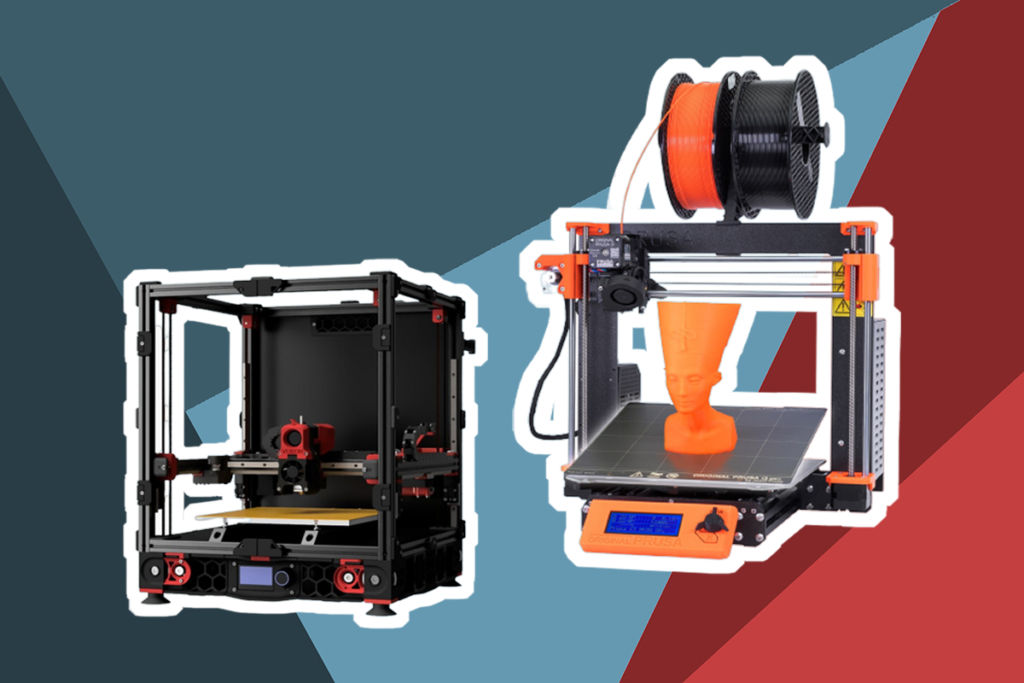

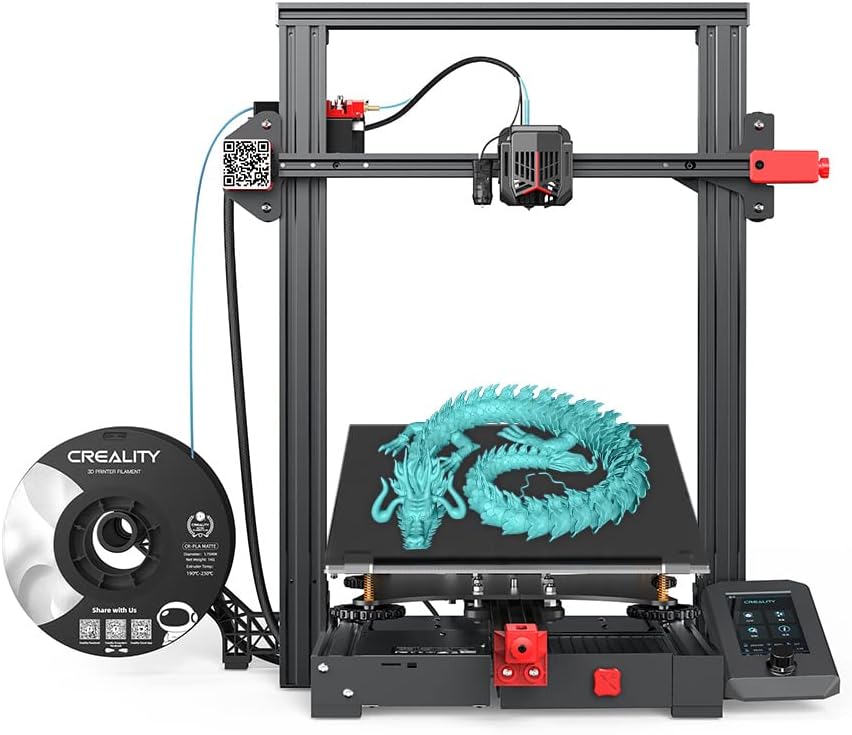

This ABS 3D printer has auto-leveling, which is leveling and printing with one touch. The touch screen is large with a simple user interface. It prints silently. It uses fused deposition modeling and has a large build volume. It supports many filaments, so you have many options for what materials you want to use.

This is the perfect 3D printer for someone who wants high quality but is also on a budget. It has many great features. The print speed can go up to 180mm per second. You can use a lot of different filaments with it. It has a great computing system and touchpad. This printer leaves little to be desired, especially at its price point.

More features: high precision printing, flexible filament, double Z-axis

This advanced ABS 3D printer has many extra features to make it stand out from the crowd. It has two sets of extruders that each use a different filament. It also has a double Z-axis that prevents jitter. Everything about this printer is of the highest standards, and you can get customer support within 24 hours of your question.

This is the printer to buy if you are looking for an industrial-grade ABS 3D printer. It has a large 5-inch touchscreen, so it is easy to view and incredibly user-friendly. You can use this machine for over 24 hours, and it will still stay stable. Over 10,000 users choose this printer each year. It includes at least two technical upgrades per year.

More features: double extruder, metal platform

This ABS 3D printer is compatible with many different types of filament. It has a guide rod to make precise movements on the Z-axis and to keep the flatform arm from getting deformed. The aluminum plate is thick so that it is fully flat and will not warp when the machine heats up. It has an enclosed chamber.

This model is a huge improvement over the original Creator. One of the main improvements is creating a metal frame that is incredibly stable as compared to the original frame that was made out of wood. The aluminum plate is thicker so that it stays flat even when heated. Like the original Creator, there is a full warranty.

More features: sensitive touch screen, filament sensor, quick set up

This is a simple and practical ABS 3D printer that can get the job done for both professionals and amateurs alike. The filament sensor is flexible. It has a full-color touch screen and quick, easy assembly. The layer resolution is as good as 50 microns. It supports many materials, so you won’t run out of options and can truly customize what you are building.

This model is great for amateurs and professionals alike. No matter what your needs are, this abs 3D printer will meet them. It can be used at work and then brought home for pleasure printing. This is a great printer for people who want versatility and the ability to get professional-grade products at home.

More features: metal frame, easy leveling, fast heat-up bed, large build volume

This is a great ABS 3D printer. The bed heats up quickly, so you don’t have to wait a long time before building. It levels extremely easily with big knobs. The build volume is large, so it won’t limit you. It also supports many materials, so you can build with nearly anything you could desire. It has a single extruder.

This printer is great for people who want something simple to use. It doesn’t have many fancy features that you have to take the time to learn. You can simply start building. Leveling your project is extremely simple, and the quick heat up means you can build nearly right away. This is a great beginner printer.

ABS is a very common filament in 3D printing. ABS stands for Acrylonitrile Butadiene Styrene. It molds very easily when it’s hot and hardens smoothly when it cools down. It can take a lot of forms and still stay high quality, so it becomes used in a lot of manufacturing that is traditional in many industries, and it is also used by hobbyists who use ABS 3D printers.

ABS is very durable. It is a thermoplastic that is used for rapid prototypes and to test products. It also is a good electrical insulator. It has high-temperature resistance and is flexible. It is also strong, which makes it good for engineering. It can be finished with acetone for a shiny and smooth finish.

Using an ABS 3D printer means you can get all of the high-quality features of ABS while at home creating whatever you wish. You don’t have to be a manufacturer to get the perks of ABS. Even if you are just creating miniature creatures, they can be extremely high quality with these printers.

There are a few key features to look at when considering which ABS 3D printer is the best one for you. One thing to look at is the printing technology. All of the printers we reviewed use FDM printing technology. Accuracy is another thing to consider. Accuracy is how close your model is to its true value. While ABS is an incredible material, it is good to have a printer that can use other materials, too, in case you want to experiment. The build volume is how much room you have to build and is important if you want to be making large builds. Resolution is how accurate your printer is. Every printer has an ideal printing speed at which it is most accurate. Lastly, each printer uses different amounts of power.

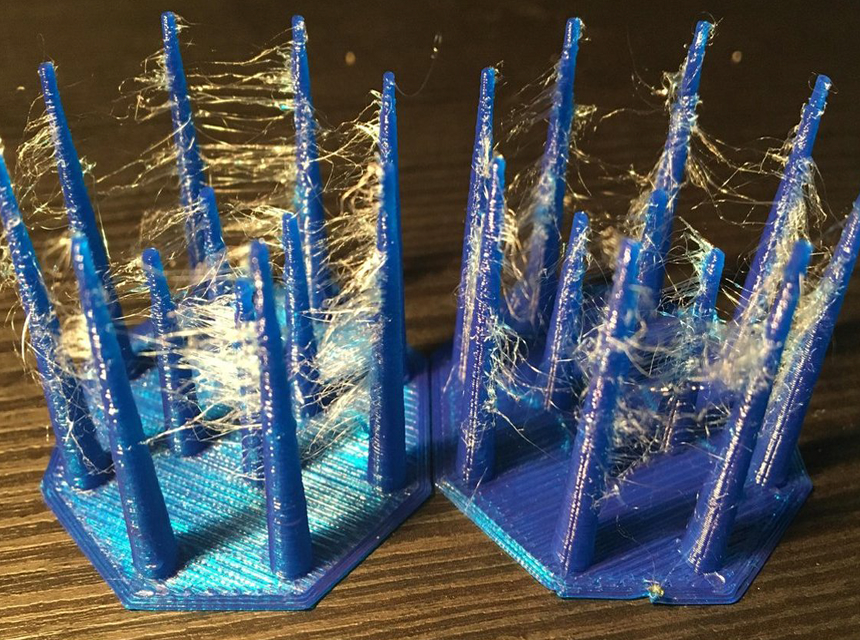

All of the printers we reviewed in our ABS 3D printer review use fused deposition modeling, or FDM, printing technology. FMD technology deposits ABS in accordance with a pattern that is specific to that design. It can be used for very important scientific discoveries Trusted Source Understanding and improving FDM 3D printing to fabricate high-resolution and optically transparent microfluidic devices - Lab on a Chip (RSC Publishing) The fabrication of microfluidic devices through fused deposition modeling (FDM) 3D printing has faced several challenges, mainly regarding obtaining microchannels with suitable transparency and sizes. Thus, the use of this printing system to fabricate microdevices for analytical and bioanalytical application. pubs.rsc.org as well.

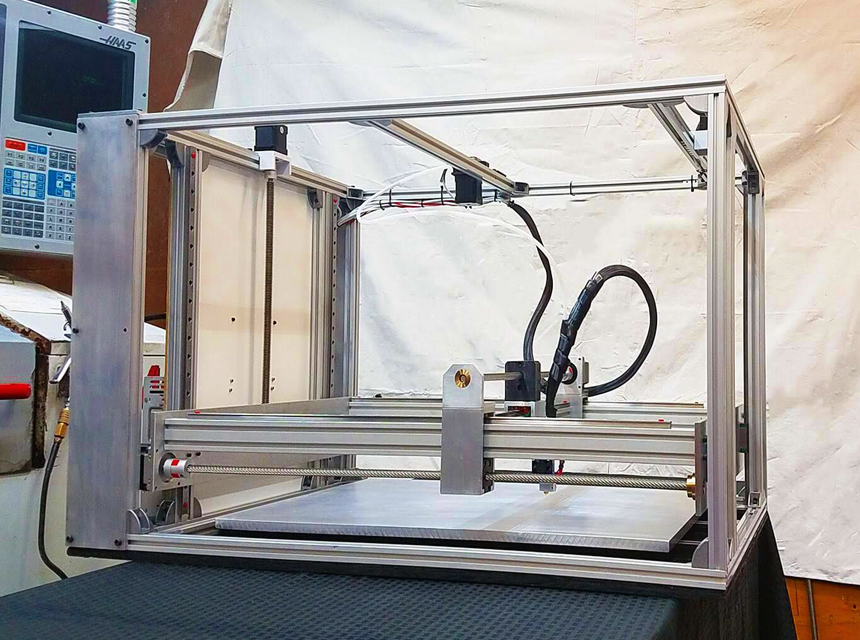

The layout of FDM has a printhead that moves in 2D along an X and Y axis on top of a platform for building. The ABS gets pushed through a nozzle that is heated up and gets laid out in layers based on the CAD design. Then the build platform gets lowered, and another layer is laid down until the design is finished.

FDM is a great option of printing technology for ABS 3D printers because it doesn’t need a solvent that is organic, and you don’t need to remove extra powder from polymers. However, it does happen at very high temperatures in order to melt the ABS, which means there is a limit to the encapsulation of the biomolecules in the resulting build.

The definition of accuracy can be conceptualized using a target. Accuracy is how close the measurement is to its value that is true. You can imagine true value as the bullseye. Your shot is more and more accurate the closer it gets to the bullseye. Now let’s transfer that to the world of ABS 3D printers. The true value is the dimensions of your CAD design. It is how close the 3D print comes to the design in CAD.

The accuracy is measured in millimeters and means how many millimeters it is from the true value. It is measured for the X, Y, and Z axes.

We reviewed printers that use ABS material in our ABS 3D printer review. ABS filament is a great material to use. It is a very strong thermoplastic. It is used for prototyping rapidly and also for manufacturing to testing products. It is also a good insulator and is perfect for engineers. It can also be processed with acetone for a fantastic finish. While ABS has all these perks, the printers we reviewed can also use other materials Trusted Source The Plastics of 3D Printing | Tools, Publications & Resources The substrate for FDM printers are almost exclusively some form of thermoplastic that is delivered in an extruded wire-like form on a spool. It is usually called “filament” in the generic. The two common diameters for use in FDM printing are 1.75mm and 3mm, and a specific diameter is called for by the print head being used for the printer in question. A printer that uses 1.75mm diameter filament won’t be able to use 3mm without retrofitting the hardware for the difference, and vice versa. Slightly more common, the 1.75mm diameter is used by Makerbot Industries, the most popular manufacturer of FDM printers. www.ala.org too.

The ANYCUBIC i3 Mega S can use TPU, PLA, ABS, HIPS, and Wood. The ANYCUBIC 4Max Pro 2.0 can use ABS, TPU, PLA, HIPS, etc. The ANYCUBIC Vyper can use PLA, TPU, ABS, PETG, and Wood.

The build volume is the amount of space you have to build your model. This is extremely important if you want to build big models or if you want to build multiple models at once. Typically, more expensive ABS 3D printers will have a larger build value. It is a huge selling point.

If you aren’t going to build large objects, build volume isn’t something you really need to worry about. It is measured in millimeters, centimeters, or inches and is in the format of length, width, and height.

In ABS 3D printers, the resolution is an indication of the accuracy of the printer. Resolution is considered for three different dimensions. There are the 2D dimensions which are planar, or X and Y. There is also the 3D dimension which is Z. The X and Y dimensions are controlled by a different mechanism than the Z dimension, so their resolutions will differ. What contributes to print quality the most is the X and Y resolution, which is the advertised resolution.

The smaller the number that measures resolution, the higher the quality of your model will be. Resolution is typically measured in millimeters or microns.

The ANYCUBIC i3 Mega S has a resolution of 50 microns. The ANYCUBIC 4Max Pro 2.0 has a resolution of 0.05-0.3 mm. The ANYCUBIC Vyper has a resolution of ±0.1mm. The R QIDI X MAX 3D Printer has a resolution of 100-500 microns. The FlashForge 3D Printer Creator Pro has a resolution of 100-500 microns.

Printing speeds of ABS 3D printers come in a range along with a recommended speed. The recommended speed is the speed at which the printer functions best and is the most accurate. That is why the resolution sometimes is a range; it depends on the speed.

The speed determines how fast the motors of your extruder move to push out less or more ABS material.

If you’re short on time, you can speed up your printer within its limits. But your quality of print may suffer if you go above the recommended speed. The same can be said of a speed that is too slow. This is why printers have recommended speeds.

The ANYCUBIC 4Max Pro 2.0 has a print speed of 20~150mm/s (suggested 50mm/s). The ANYCUBIC Vyper has a print speed of <180mm/s (recommended 80-100mm/s). The ANYCUBIC Mega Zero 2.0 has a print speed of 20~100 x mm/s (suggested 60mm/s).

Something that should be on your mind is how much power your ABS 3D printer uses. Power is the equation of current multiplied by voltage. The parts of the printer that use power are the lights, the hotbeds, and the heated beds. The majority of 3D printers use 50 watts of power per hour. If you are going to be running your printer a lot, the power usage of your printer is something to consider because it can actually affect your electric bill.

Throughout our ABS 3D printers review, we touched on six different amazing printers. However, three of them are undeniably the best choices: our Editor’s Choice, Best Value, and Premium Pick. Our Editor’s Choice, the ANYCUBIC 4Max Pro 2.0, comes fully assembled. It has an auto-off safety feature so that children can use it as well. It has a responsive touch screen as well as new knobs and a new fan.

Our Best Value, the ANYCUBIC Vyper, has auto-leveling, an easy touchpad, and a large build volume. It prints silently and accepts many different types of materials. The QIDI TECH X Max 3D Printer has the most number of extra features like two sets of extruders and a double Z-axis. So, if you’re looking to buy the best ABS 3D printer, look no further! These three are your top picks.