Polycarbonate filament is a must-use material for many 3D materials, thanks to its durability and heat resistance. According to a study by Harvard, it can even be used to manufacture 3D printed material for aeronautic applications. However, if you don’t find the right 3D printer, your polycarbonate projects will fail before you’ve even started. To save you from wasting time and money, we reviewed the best polycarbonate 3D printers on the market and ranked them on our list of favorites.

When choosing our top picks, we considered specific factors like material quality, software, features, and cost to determine which polycarbonate 3D printers can provide you with the most value. Whether you are new to the world of 3D printing or you’re a professional printer looking to incorporate polycarbonate fiber into your projects, there’s something for everyone here.

More features: industrial grade, high precision printing, redesigned UI interface of QIDI software

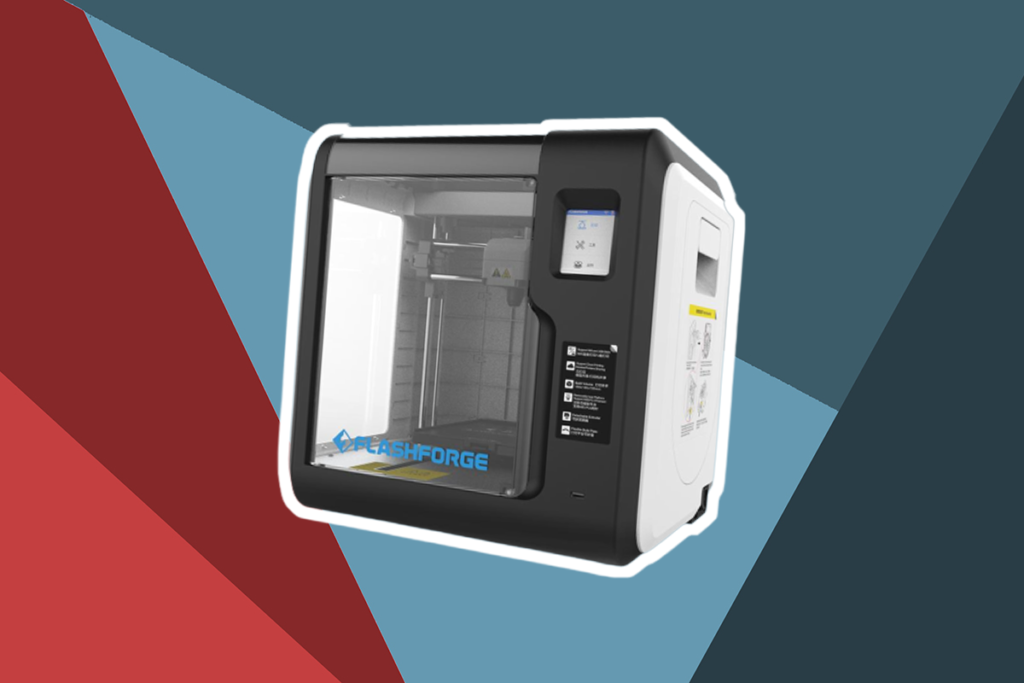

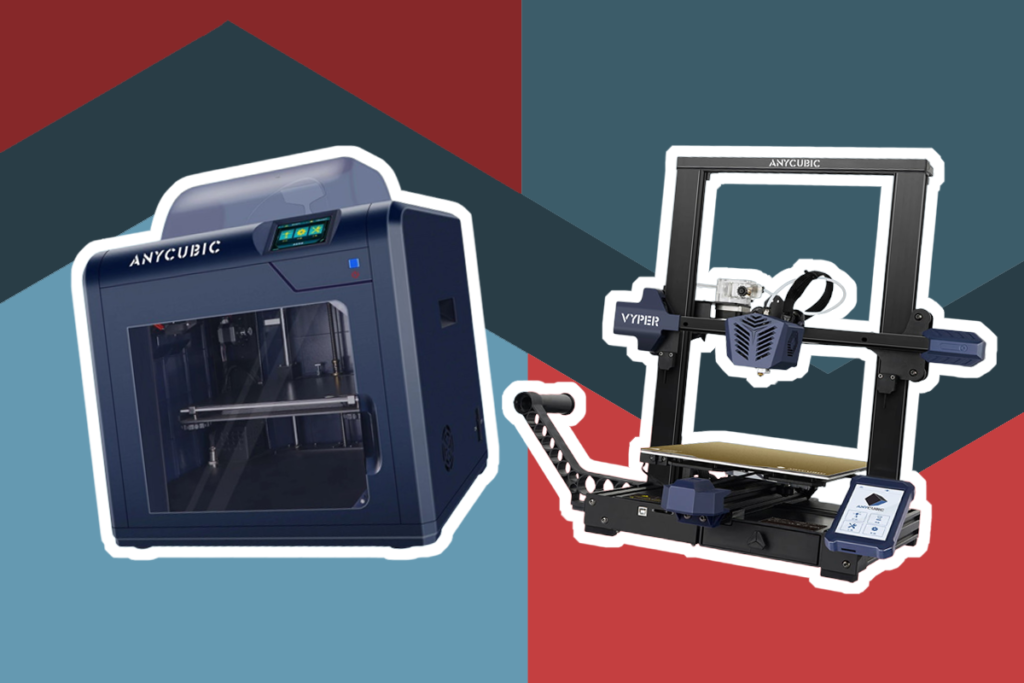

If you’re looking for a polycarbonate 3D printer that offers useful features and impressive versatility for a mid-range price, the Qidi X-Plus is the right choice for you. Designed with quality and affordability in mind, this machine successfully strikes a balance between the two by offering features like a double-sided print bed, two interchangeable extruders, an intuitive interface, and high precision printing for less than $1000.

Qidi is one of the leads in 3D printer manufacturing, and its X-Series of printers offer users a wide range of options. The X-Plus is one of their larger printers, boasting a 4.3” color touchscreen as well as the original creation of the AB extrusion system and removable magnetic platform sticker.

More features: built-in HD camera, heated build plate, 5-inch full-color touch screen, automated 9-point leveling

The DigiLab 3D45 is an incredibly reliable machine built for heavy usage and high-quality results. Featuring a direct drive, metal extruder for smooth 3D prints, filament run-out detection that resumes printing where you left off, and a built-in automatic leveling sensor, we consider this premium printer to be the best choice for those who can afford the hefty price.

While many 3D printer manufacturers are scrappy startups, Dremel is an exception. The company has made a name for itself by producing quality power tools over the past 85+ years, and they clearly put the same care into crafting their flagship DigiLab 3D printer. The DigiLab 3D45 is a good fit for engineers, professional product developers, and tech-savvy hobby printers alike, thanks to Dremel’s top-tier design.

More features: resume print technology, lattice glass platform, run put detection

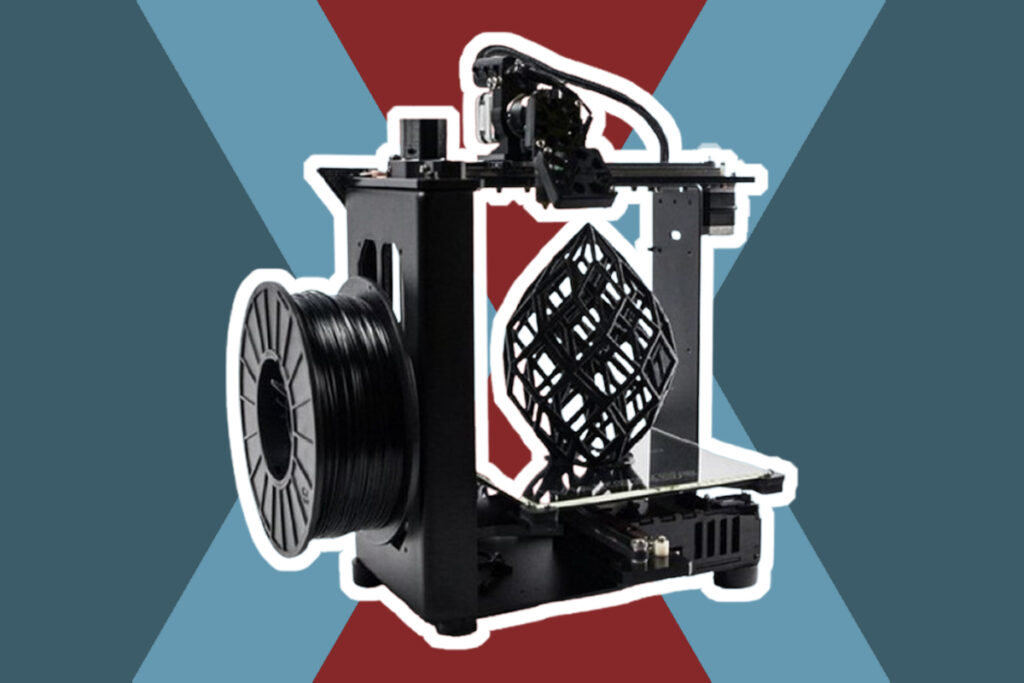

The Gantry Pro is worth exploring if you’re looking for an affordable printer that doesn’t skimp on features. With its large print area, lattice glass platform, and resume print technology, this machine offers premium features that aren’t typically found on other printers in this price range.

Recent upgrades have made the Gantry Pro unbeatable when it comes to providing users the best value for a low cost. Gantry made notable improvements, such as the addition of dual z-axis motors and dual y-axis tracks for more accurate printing, extended filament compatibility for a greater range of projects, and a Titan Direct extruder for smoother, more convenient extrusion.

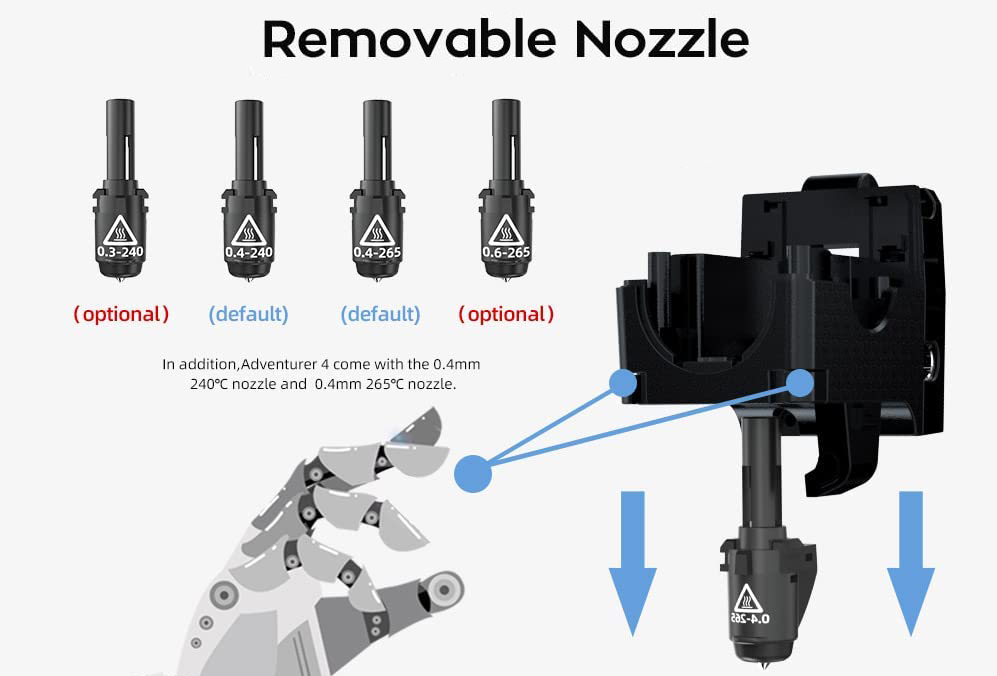

More features: auto-leveling, removable high-temperature nozzle, magnetic flexible CNC platform, HEPA13 Air Filter, filament detection

With its larger build volume, remote print management capabilities, and swappable nozzle design, the Adventurer 4 aims to please a wide variety of users. Casual hobbyists, professional designers, and educational institutions alike have chosen this machine for its dazzling array of features, making it our top choice for a versatile polycarbonate 3D printer.

The Adventurer 4 is the latest printer from FlashForge USA and offers several much-needed feature upgrades from its predecessor. Like the Adventurer 3, this printer features a fully enclosed build chamber and rugged polymer casing, but its build volume is noticeably larger. The modular extruder setup of the Adventurer 3 is also included, but now you can expect higher nozzle temperatures with a greater range of material compatibility.

More features: filament detection, touch screen, demountable glass bed, dual extruder, Wi-Fi control

The Bibo 2 Touch surfaced on Amazon around 2016 and has since gained massive popularity, with over 500 positive reviews and regular placements on bestseller lists. Bibo is a lesser-known 3D printing manufacturer based in China, so you may be tempted to pass this printer up in favor of a more expensive option from a big-name printing company. But with features such as dual extruders, filament detection, add-on laser engraving module, and full-color touch screen, the Bibo 2 Touch definitely lives up to the hype.

This machine’s many powerful features make it a solid choice for beginners. Assembly typically takes less than an hour since it comes 95% assembled. And with larger z- and x-axis guide rods than many printers on the market and a demountable glass bed for easy removal, beginners can learn 3D printing with less trial and error.

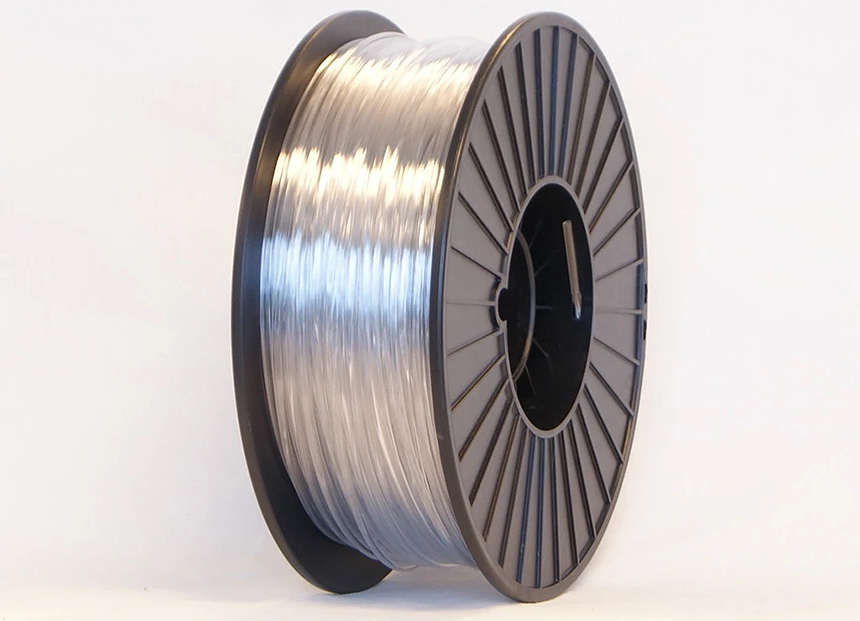

Polycarbonate filament is strong, durable, and incredibly tough. As a naturally transparent thermoplastic, it is unique in its high-impact and heat resistance, but it is more prone to warping than most other transparent materials. While it is an ideal material for countless projects, not every 3D printer can successfully print with polycarbonate filament.

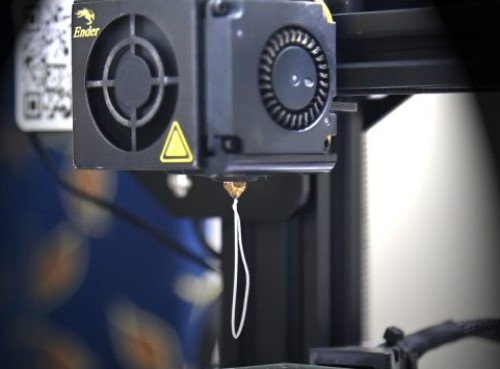

Because of its fickle nature, 3D printing with polycarbonate filament requires a very high ambient temperature along with a high-performance nozzle if the printer cannot achieve a high enough temperature, the polycarbonate filament with separate or begin to crack between the printed layers.

While advanced features will depend on the amount you’re willing to pay for the machine, the most important factors to consider when searching for the best polycarbonate 3D printer Trusted Source Polycarbonate based multifunctional self-sensing 2D and 3D printed structures for aeronautic applications - NASA/ADS Different polycarbonate materials have been reinforced with carbon nanotubes to tune electrical conductivity and to induce piezoresistive self-sensing capabilities. Further, the composites were processed by solvent casting and fused deposition modelling (filament for 3D printing) methods. An electrical conductivity percolation threshold of ≍0.3 wt.% has been found for solvent casted films, whereas samples processed by 3D printing show higher thresholds, ≍2 wt.%, presenting all samples a similar maximum electrical conductivity, thermal and chemical properties. ui.adsabs.harvard.edu are always going to be the same. For our recommendations, we looked for specific selection criteria such as quality software, compatible printing materials, a large build volume, a removal printing plate, adjustable nozzles to account for layer thickness, and a valuable warranty.

Some printer software simply doesn’t offer options for working with polycarbonate filament, which can be a challenge for inexperienced users. Look for polycarbonate 3D printers that offer robust, feature-rich software like the Dremel DigiLab 3D Printer, whose DigiLab 3D Slicer software includes built-in profiles for working specifically with polycarbonate filament. As a bonus, their user-friendly interface can save you a lot of frustration when it comes to adding additional printing profiles.

As we mentioned above, polycarbonate filament is a very strong material and therefore takes a lot of heat to print with. If the 3D printer’s casing is flimsy or low-quality, it is a guarantee that it won’t be able to hold up to the high temperatures needed for a successful polycarbonate project.

To successfully print using polycarbonate filament, your 3D printer requires a nozzle that can reach temperatures between 500- and 590-degrees Fahrenheit, as well as a heated printing plate that can reach up to 300-degrees Fahrenheit. Not every printer can achieve these high specifications, which can be the biggest barrier when it comes to using polycarbonate filament in your 3D printing projects.

In addition to reaching the required high extruder and plate temperatures, an enclosed print chamber can help manage the heat and prevent any deformation to the polycarbonate filament during printing.

Printers with robust, reliable hardware, such as the FlashForge Adventurer 4 3D Printer or the Dremel DigiLab 3D Printer, are ideal here. They both feature an enclosed build chamber along with a sturdy metal casing and high-temperature extruders, so they can stand up to the heat and produce consistently great results.

The build volume of a 3D printer is exactly what it sounds like: the maximum size of any object you can print. This might go without saying, but the larger the build volume of a printer is, the more variety you have when it comes to projects.

If you’re a casual hobbyist, you may be tempted to buy a 3D printer with a small build volume so that it may fit on a personal desk easier. However, consider the fact that many projects involving polycarbonate filament tend to be on the larger side. A small build volume will greatly limit the size of the projects you can make.

For beginners searching for the best polycarbonate 3D printer, aim to find a machine with a larger build volume that doesn’t come with a massively high price tag. Printers like the ADIMLab Gantry Pro 3D Printer and the R QIDI TECHNOLOGY 3D Printer give you the ability to create polycarbonate projects without compromising on size.

There are many different types of printing plates, but not all of them are convenient to use with polycarbonate filament. In addition to proper heat management, another crucial factor for polycarbonate printing is plate adhesion.

Polycarbonate filament is one of the more difficult high-performance materials to print with due to its tendency to warp and shrink, so strong plate adhesion is a must.

Look for a 3D printer that features a removable printing plate that provides easy adherence, such as the R QIDI TECHNOLOGY 3D Printer’s magnetic plate sticker, the ADIMLab Gantry Pro 3D Printer’s lattice glass plate, or the BIBO 3D Printer’s demountable glass platform. These printing plates are well-suited to the high temperature needed to print with polycarbonate filament, provide an effective surface for the project to adhere to, and can be easily removed for more convenient project separation.

The ideal space left between the nozzle and plate should be 0.1mm, while the recommended wall thickness of the polycarbonate itself is a minimum of 1.2mm. Since it is critically important to adjust the nozzle height to compensate for the added thickness of the plate surface, a modular extruder setup like the one found in the FlashForge Adventurer 4 3D Printer is ideal. The nozzle can be detached and reattached quickly for easy repositioning.

While a high-quality printer can provide months of use without issue, a warranty can go a long way in terms of security. Look out for printers that include a warranty of 12 months or longer, like those found with the BIBO 3D Printer or R QIDI TECHNOLOGY 3D Printer.

Some polycarbonate 3D printer manufacturers even allow resellers to offer warranty support, which can be helpful for quick, convenient repairs. However, other manufacturers do not, so it is important to consider which option would provide you with the highest value.

It has been used by professional 3D printers in a variety of industries, such as for skylights and security lights in buildings, room dividers for office spaces, and siding for agricultural greenhouses. A team of engineers even used polycarbonate filament to build an entire house Trusted Source 3D printed house: Builders say the method will reduce new home construction costs - CNN The company can set up its Autonomous Robotic Construction System at a build site in six to eight hours. It then lays concrete layer by layer, creating footing, the foundation of a house and the interior and exterior walls of the structure. www.cnn.com , according to CNN.

Since it is a relatively cheap and easy to form material, if you have the right printer, it can be used in many everyday applications as well. Simple projects that utilize polycarbonate filament may include phone cases, digital data storage devices like DVDs and CDs, baby bottles, and food containers. However, due to its strength, heat resistance, and flexibility, it can also be found in more advanced projects such as medical devices, bulletproof glass, telecommunication hardware, automotive parts, or electrical components.

As a general guideline, always clean the printing plate once it has cooled using an IPA concentration or specialized cleaning solution. Soak a paper towel, microfiber cloth, or cotton ball with the IPA concentration and clean the surface of the printing plate in a circular motion. Repeat until the plate is free of any oils, fingerprints, or leftover printing filaments that can lead to imperfections during your next printing project.

If your printer has a glass base, you may need to use a scraper to remove any additional residue as well. If you have a demountable printing plate, we recommend removing it before cleaning since this can help you avoid damage.

Clear out the extruder by removing any remaining filament that has leaked through the nozzle to prevent clogging in the future. Some people find that using a nylon cleaning filament when switching filaments also helps to clear out any remaining filament that refuses to be dislodged. You should also clear debris from the nozzle’s exterior by using a wet cloth or alcohol wipe while the nozzle is still hot. If this doesn’t work, use a small wire brush or blade to scrape off the remaining debris.

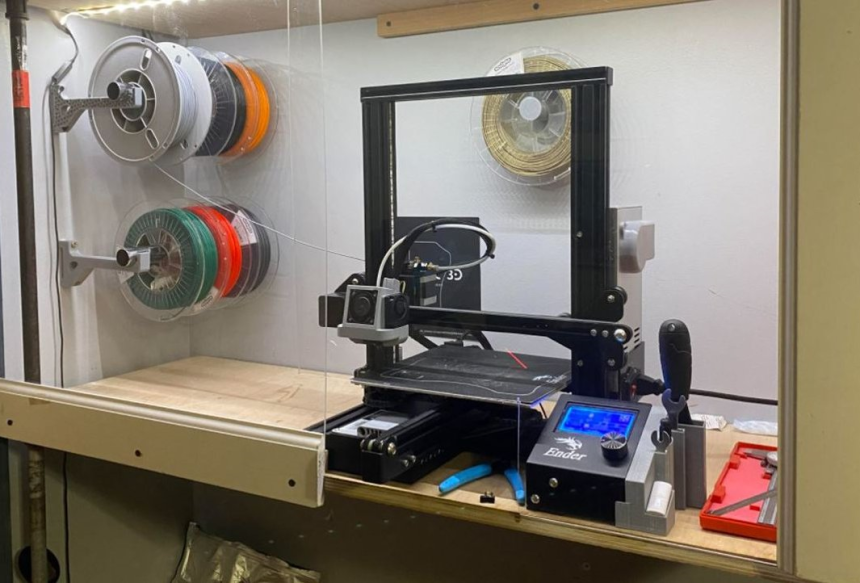

Leave plenty of room beside the 3D printer for the wash and cure systems, as well as an area to store your parts. Some essential 3D printing parts, such as filaments, can be rendered unusable if they aren’t properly stored, so make sure to keep them in a moisture-free, air-tight container such as a dry box, dehumidifier, or vacuum bag.

Depending on the projects you’ll be printing, you may wish to set up a finishing station near your printer to store projects that require gluing, polishing, or painting. No matter what, always make sure that your 3D printer has plenty of space surrounding it and is clear of any dangling items that might touch it while it is printing.

Whether you’re just entering the world of 3D printing or you’re a professional who wants to incorporate polycarbonate filament into your 3D printing projects, scouring the internet for the best polycarbonate 3D printers can be intimidating. Knowing what to look for can take a lot of frustration out of the process, though, so with our top picks, you can breathe a sigh of relief.

For the most bang for your buck, the ADIMLab Gantry Pro 3D Printer holds the title of our Best Value 3D printer for projects using polycarbonate filament. With a score of 8.9, the Gantry Pro delivers high-quality features not typically found in other affordable printers in the price range.

With a score of 9.5, the Dremel DigiLab 3D Printer affords you premium quality printing, an intuitive interface, and a reliable machine for any type of user.

R QIDI TECHNOLOGY 3D Printer simply can’t be beaten. Boasting high-quality features, updated slicer software, and a 4.3” color touchscreen, this robust 3D printer deserves its spot as the best polycarbonate 3D printer with a score of 9.9.