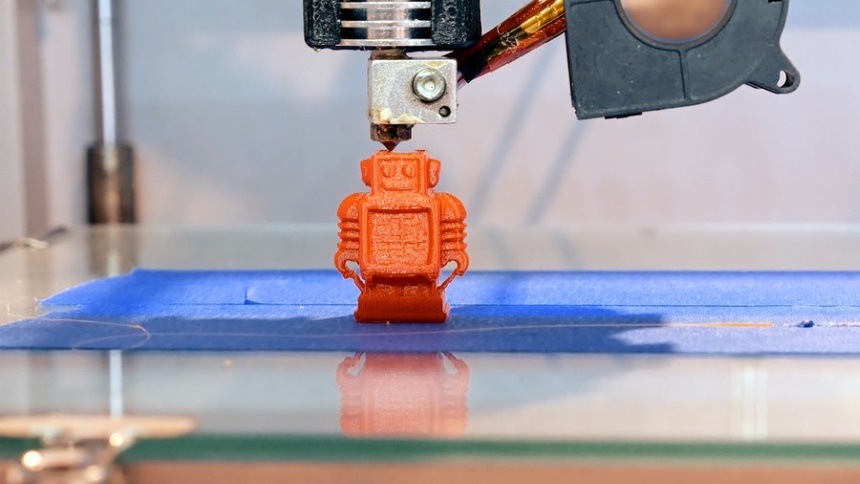

There are a lot of issues you might encounter when working on a 3D design. One of the most common issues during 3D printing is layer shifting. This error usually occurs around the axis, leading to a shift from the middle of the print along with the layers.

You might face this common misalignment that may cause irregular movements on the X or Y, and sometimes it could be a combination of the two. Generally, layer shifts are often an issue 3D designers face while printing, which could make a seemingly great work turn out awful.

From this article, you will know more about 3D printing layer shifting and how to avoid them when creating your 3D designs effectively.

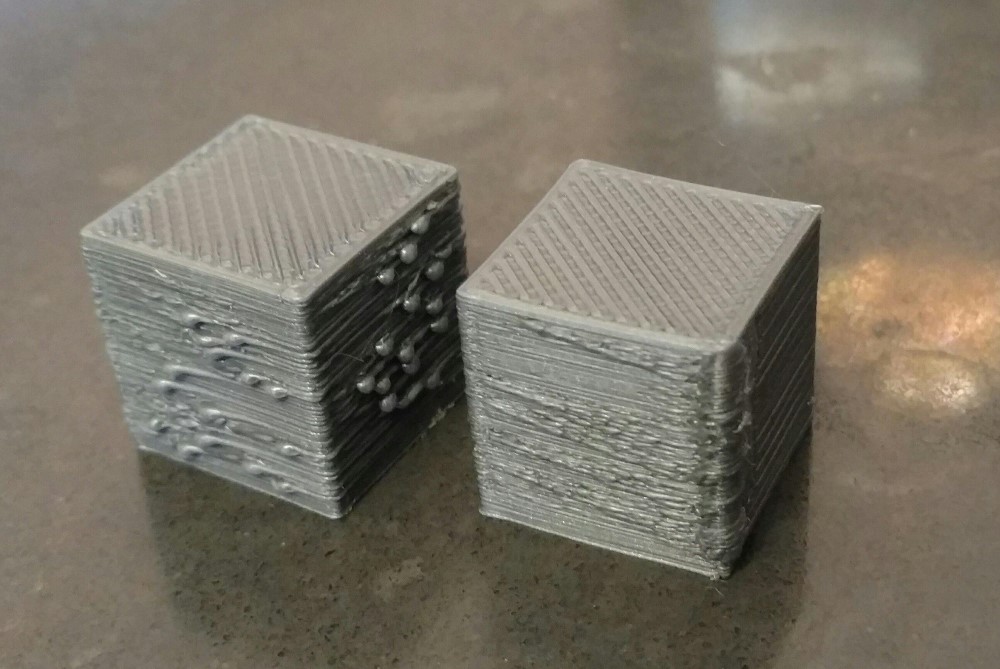

Layer shifting can be really annoying for any 3D designer as it messes with the dimensional accuracy and overall look of a print. When a layer shift occurs, you will likely get patterns and directions on the axis, different from previous dimensions.

Since these shifts are not intentional, you often get various alignment errors that make all effort put into the print a total waste. An improper alignment of layers can destroy an entire print.

While 3D printing problems layer shifting usually occurs in specific model sites, it irreversibly affects the rest of the print design. The issue could be as minor as a slight shift from one axis to another or a major mistake like failing to include a design. Either way, the print will become useless.

Layer shifting is the last thing any designer would want to experience while printing. This misalignment often leaves a designer wishing there was a “Ctrl + Z” option available. Unfortunately, it is impossible to undo any layer shift during prints which means you’d have to dispose of the affected model.

There are many different possible factors responsible for a layer shift while printing. Here are some common issues that explain what causes layer shifting in 3d printing.

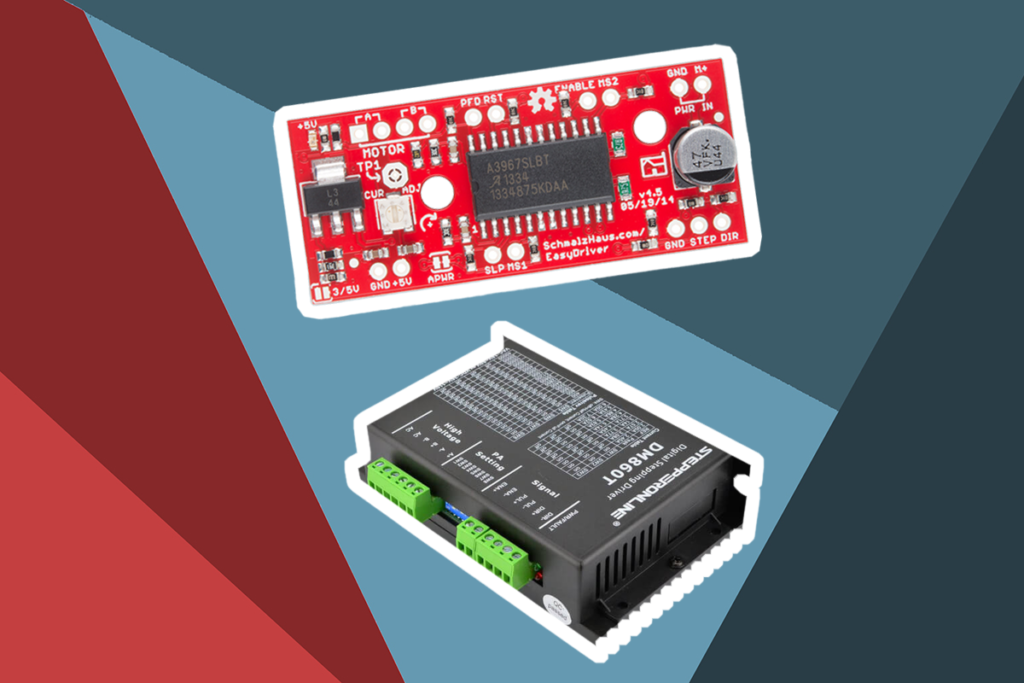

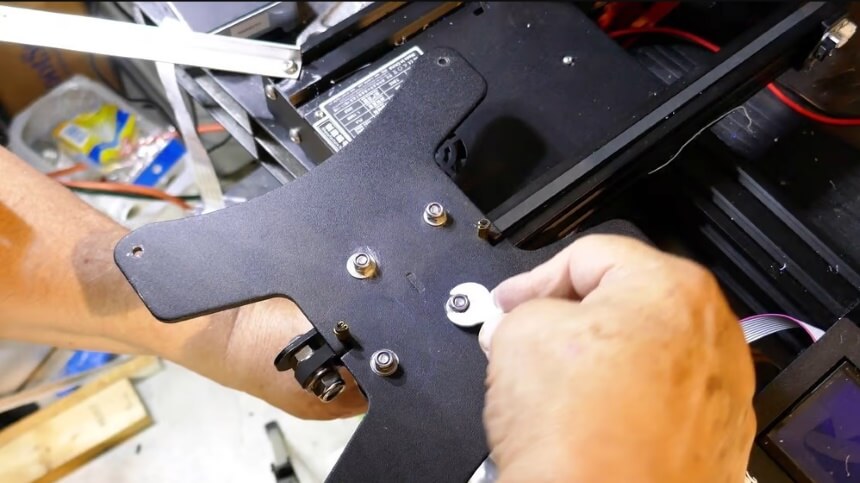

So you may be printing pretty fast with a loose belt which will likely cause a layer shift. The solution to this issue is quite simple. You must always ensure that the pulleys attached to each motor are perfectly in place.

Also, you should tighten down the small set screws that hold the pulley and the motors together to avoid any loose-fitting. This will help keep the motors firm and in place even if the motor shaft has a horizontal surface. A steady pulley will prevent a staircase effect layer shift.

Basically, the pulleys on the X-axis and Y-axis must be correctly aligned, so the motor pulley and the belts are moving in the same direction.

Once this happens, the rest of your printing will lose the preferred dimensions and render the model useless. Do not be hesitant to reduce the printing speed anytime you notice your printer may be moving too fast.

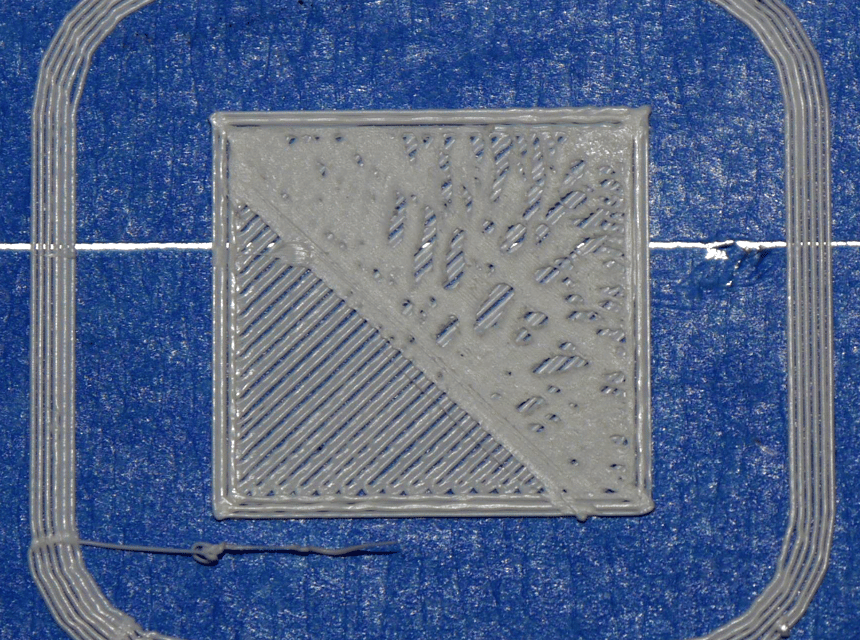

The X/Y axis movement speed determines how fast or slow the printer runs through the model.

If the movement speed is too high, you will likely experience a shift. If you use advanced settings, then you should be able to navigate your way through the speed option and adjust the acceleration.

However, to control the speed movement on the general settings option, here is what you should do.

First, choose the “Edit Process Settings” and select the Speeds tab. Then adjust both the “Default Printing Speed” and the “X/Y Axis Movement Speed.” You can now reduce the acceleration speed to a level your printer can handle well enough.

Once your layer folds, it will become difficult for the nozzle of your 3D printer to move along your model smoothly, thereby shifting your print. With the best 3-in-1 3D printer, you will get multiple functions that simplify printing.

Layer shifting destroys prints in ways that leave no room for correction. Typically, each layer should move in one particular direction without stutter, which is a notable feature the best auto-leveling 3D printer offers.

While it is almost impossible to undo a layer shift, you can try a few tips to improve your models and attract minimal issues during printing. There are ways to ensure that your 3D printing process is error-free and devoid of layer shifts. Here are a few practical tips to easily guide you through your 3D printing.

So you should ensure that your nozzle and other parts are well-calibrated and function optimally without any issue. If any part of your 3D printer is faulty, you will very likely experience mishaps while printing, which could ruin your prints.

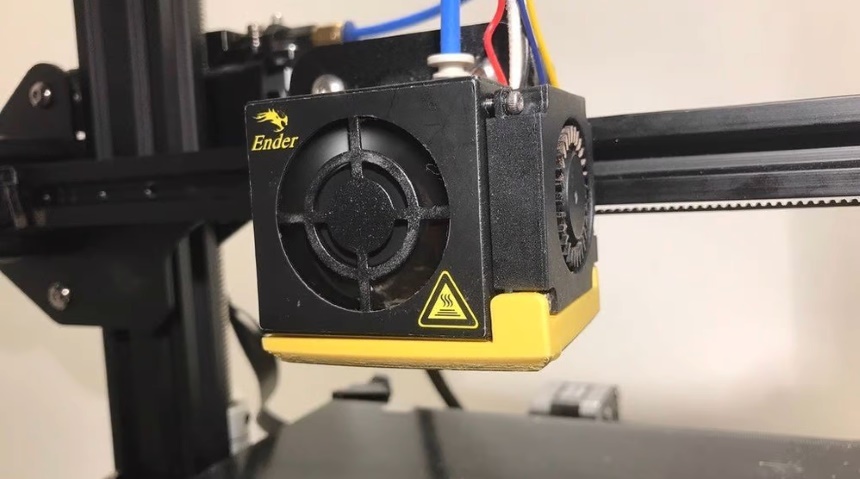

Your Ender could use a few calibrations, such as adjusting the nozzle temperature and print speed, fastening all necessary screws that hold the parts in place. With an idea on Nozzle Temperature Effect on 3D printed structure properties Trusted Source Nozzle Temperature Effect on 3D Printed Structure Properties This work was focused on the evaluation of the thermomechanical properties of 3D printed structures manufactured by FDM (Fused Deposition Modeling) method in dependence on the printing nozzle temperature. Two common materials designated for FDM were chosen for the experiments – poly-lactic acid (PLA) and acrylonitrile styrene acrylate (ASA). www.researchgate.net , you will discover the importance of preheating your hotend.

You should take other necessary steps like frequently cleaning or changing the nozzles tuning, and accessing different parts of your 3D printer.

You could also run through a few test prints to ensure your printer is ready for the main project. However, if you calibrate all parts of your 3D printer and are still experiencing any problems, then you should try other options.

If you notice your printer’s belt is loose, you can tighten the belts by pulling a strap or adjusting the tensioner (if available). The Ender 3 series comes with adjustable belts for more effortless adjustment. So all you have to do is twist the knob by the side to help you tighten or loosen the belt.

Getting a quality 3D printer should provide a good device parts and a tensioner for easy movements of belts. You want to ensure you do not apply too much tension on your belts as they could have a counter effect on them. While your belts mustn’t feel too loose, they mustn’t feel overly tightened.

Our next trip is to reduce all possible folds or vibrations that your 3D printer may contact when printing an object. These bumps can cause stutters as you place the nozzle along your desired direction, inevitably leading to shiftings.

Vibrations occur when your printer comes in contact with a rough surface. This is why you need a smooth surface for your printing purpose. In this case, an enclosed printer offers a better option, thanks to its sturdy frame. It would help if you considered getting the best enclosed 3D printer for better and smoother printing.

You should also add rubber vibration dampers to the backside of your printer to create a smooth surface that lacks bumps. This will be useful when printing at home Trusted Source 3D Printing in the Home: 1 In 3 Americans Ready For 3D Printer 3D printing is becoming more affordable and accessible for consumers. A recent study from, surprise, a 3D printer company reveals a growing interest in the do-it-yourself (DIY) trend. www.forbes.com .

The video below demonstrates how to fix layer shifting and prevent it from happening in the future.

3D printing is quite fun and straightforward, but it does come with its issues. Layer printing can be frustrating and annoying when working on printing projects. This simple problem can lead to more significant issues as there isn’t a quick fix for such problems.

Several issues cause this shifting to take place. Once you know the reason for these unfortunate mishaps, printing becomes error-free. If 3D printing layer shifting is something you have struggled with, this article should hopefully help you overcome this issue and enjoy making prints without problems.