A 3D printer is a tool that creates three-dimensional products, layer by layer, using a design built on a computer. In the mid-1980s, Charles W Hull made and patented the first 3D printer. The first-ever 3D printer printed an eyewash cup. There are many advantages of using a 3D printer. One of those advantages is that you are able to print on demand. You are also able to make money by using a 3D printer!

Other benefits of 3D printing include flexible designs, the speed at which you can create your project, and customization of your project. If you are interested in learning how to use a resin 3D printer, click here. 3D printers aren’t perfect, though, and they have many disadvantages. Just like with all things great, 3D printers do have their downfalls.

3D printing is a helpful tool, but it may not always be the right choice for your project. 3D printers do have their pros, but it has various cons as well. In fact, 3D printers have as many disadvantages as it does advantages. Some of these disadvantages of using a 3D printer include energy consumption, expensive materials, limited materials, and not user friendly. This post will highlight the top ten disadvantages of 3D printing.

A standard 3D printer consumes 50 watts of power an hour. That much power means a hefty power bill. A 3D printer will use 100 times as much energy as traditional manufacturing. 3D printers are better for running small batches as they do not take as long to make.

3D printers can be detrimental to the environment; the smaller the product, the less toxicity.

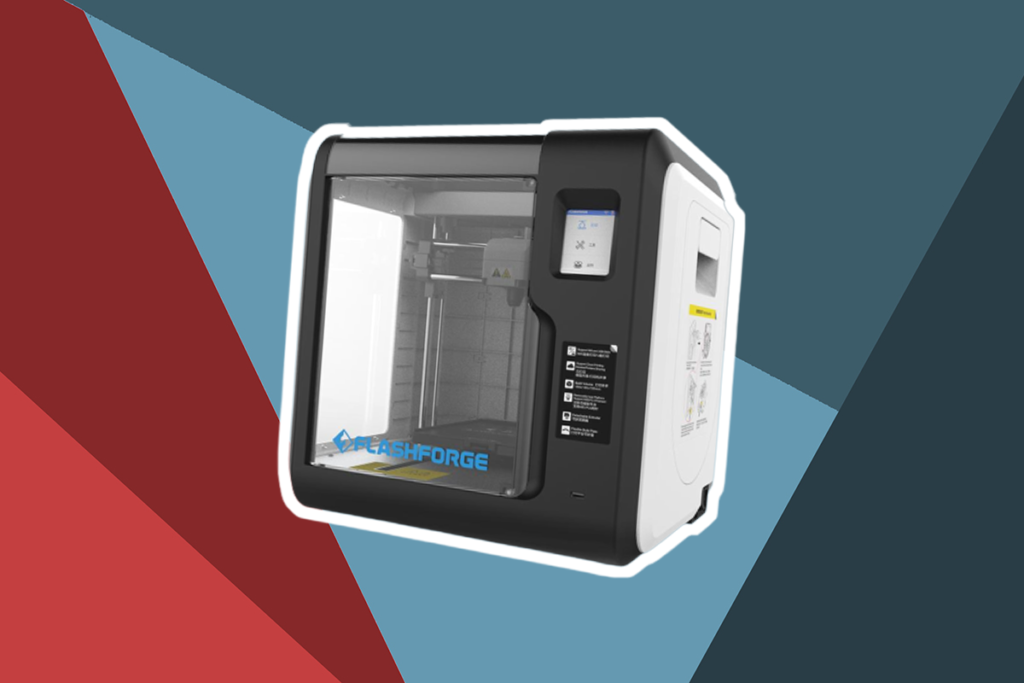

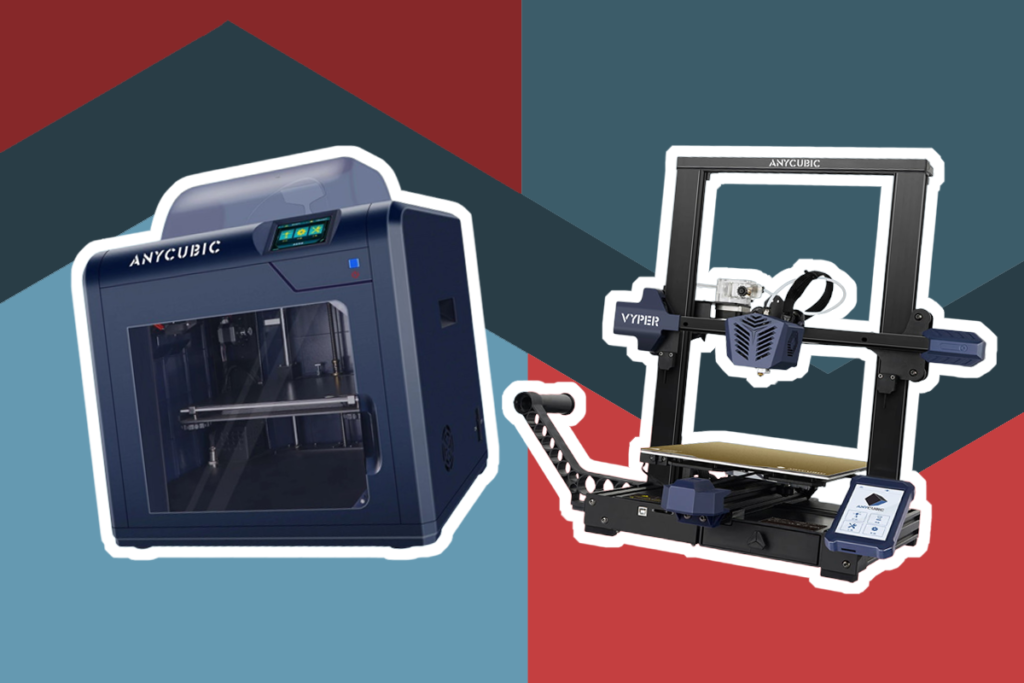

A high-quality industrial-grade printer can cost you hundreds and thousands of dollars. And that is just the initial cost! Materials will be very costly as well as your energy bill. Many businesses can’t afford to use this valuable tool even though they benefit from it. You will have to use smaller products to save money with your 3D printer. The bigger the products, the more money it will cost you. Consumer 3D printers may be cheaper, but the cost of materials and power bill would not make it worth it. The TENLOG TL-D3 Pro Independent Dual Extruder 3D Printer is a great example of a cost-effective, consumer 3D printer.

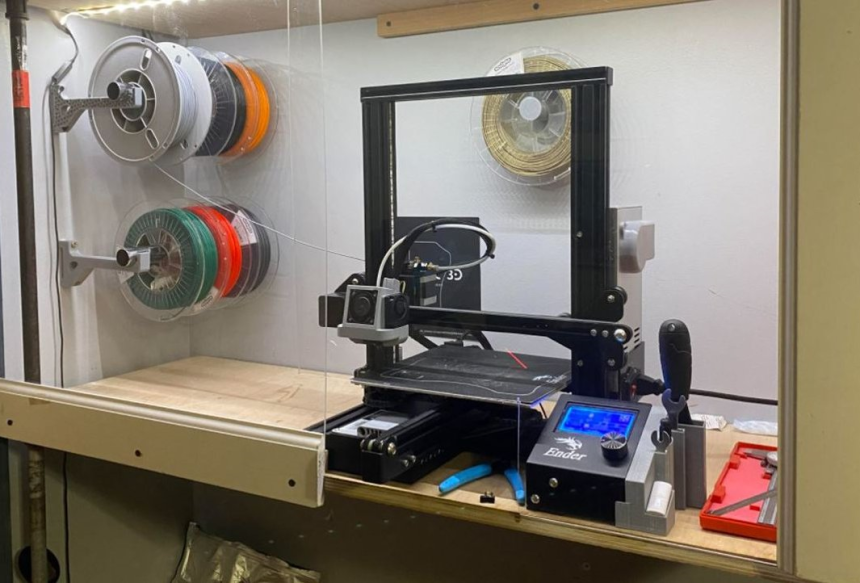

There are only a limited number of materials that can be used for 3D printers. Many of them are still in development. The primary material used with 3D printers is plastic. Plastic may not be the best material to use for your product, depending on what you are creating. Plastic varies in quality and strength, but it is easy to use. Glass and gold have been used in 3D printers, but it is not yet commercialized. Metal can also be used, but it is not as sturdy as you may think it is.

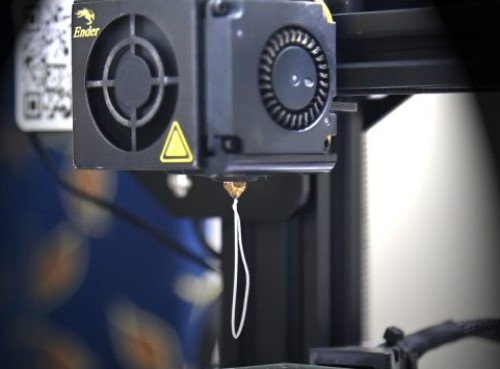

Television and the internet make 3D printers look easy to use. People are under the assumption they work similarly to computer printers. In fact, a 3D printer is a highly complex machine that runs on high voltage. Many people complain of poor connectivity as well. Although 3D printers are challenging, they are getting easier to use every day. To use a 3D printer, you will need a high voltage socket and special cartridges. Knowing what sort of filament to use for your 3D printer can also be confusing.

When used in homes and offices or other enclosed spaces, there is a chance of people breathing Trusted Source 3D Printers May Be Toxic To Humans For the uninitiated, 3D printers typically work by melting plastic filaments or other base materials such as nanoparticles, metals, thermoplastics etc. and then stacking the melted materials layer upon layer to form an object. When the plastic or other base materials are heated to melt they release volatile compounds into the air near the printer and the object. www.forbes.com in toxic, carcinogenic materials. These harmful emissions also reduce the air quality in the room.

The 3D printer emits microscopic materials, and they can enter the bloodstream. These materials are known to cause cancer and other harmful diseases such as emphysema.

Most 3D printers have a plastic filament. An example of this type of filament is the Polymaker Matte PLA Filament. Even when using raw materials, there is still excess plastic waste. This waste is then taken to the landfill. This use of plastic is negatively affecting the environment. You are also limited in the types of products you can make using plastic. When using other materials like metal, glass, or gold, you can make a wider variety of products.

Unfortunately, criminals and terrorists can easily create weapons of mass destruction on 3D printers. It is as simple as downloading a blueprint. The more 3D printing grows, the happier the criminals are getting. When a criminal creates a weapon on a 3D printer, they leave no trail of evidence for the police to follow. Knives, guns, and explosives are just some of the guns made on a 3D printer.

Criminals can also create counterfeit goods on a 3D printer. They can develop products on a massive scale. More and more counterfeit products are being made on 3D printers as they become more readily available. Inventors are having a hard time protecting their patents. Sadly, unique products will be significantly affected.

Manufacturing industries have been encountering layoffs because of new technology like 3D printers. You only need one person to operate a 3D printer as opposed to three people to complete the same job. Although this is a benefit for companies, many workers are experiencing layoffs and furloughs. It helps save the company on the cost of labor. This is detrimental to countries that rely on manufacturing-style jobs as their primary source of income. 3D printers should be used in conjunction with humans, not instead.

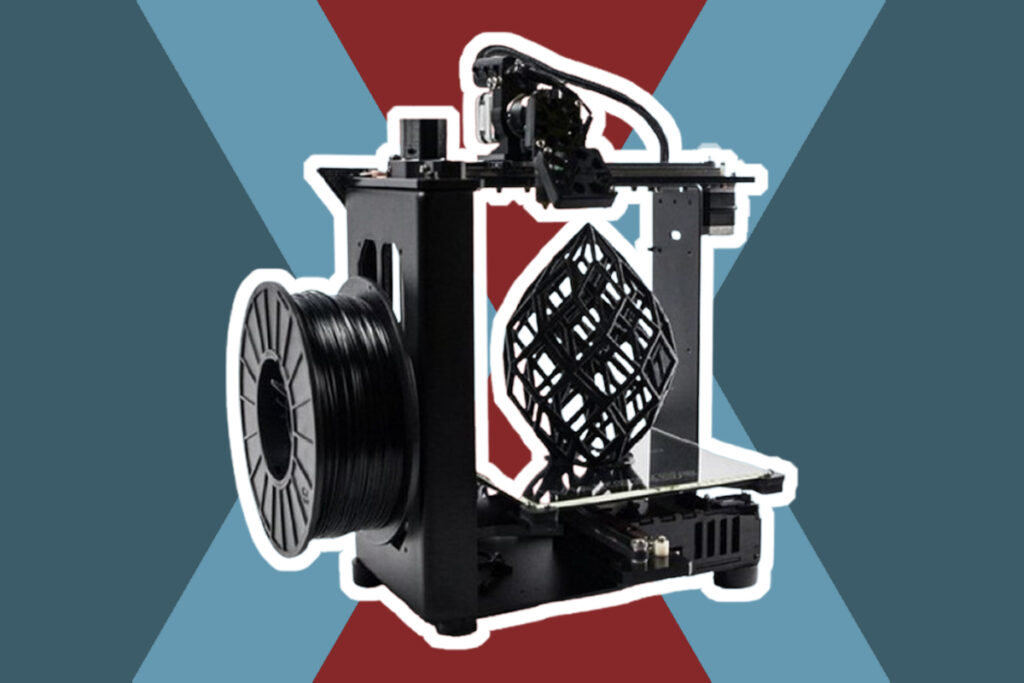

Because the chamber size on 3D printers is small, it is challenging to create your project in one complete process. Usually, parts need to be printed separately and put together afterward. This will also increase the time it takes to do your project. Not only will it increase the time it will take to complete, but you will also be losing money.

The longer the 3D printer is running, the higher your electric bill will be. The more times you use the machine, the more waste you are creating as well.

As significant and valuable as 3D printing, it has disadvantages and many kinks to work out still before it becomes more readily available. T 3D printing should not replace traditional manufacturing. In fact, it should be used in addition to conventional manufacturing. It is easy to understand the world’s fascination with 3D printing.

You can create three-dimensional products in a matter of minutes! It truly is revolutionary. That being said, though, not everyone who uses a 3D printer has the best intentions. They will use it to create unlicensed weapons. 3D printers also generate a lot of waste and can emit harmful toxins. When using a 3D printer, beware of all of its flaws and how