Have you ever made jewelry as a kid? Did you know that you can make jewelry as an adult using a 3D printer for jewelry making? The best 3D printer for jewelry has many different features that we reviewed. Printing technology is the mechanics of how jewelry is made. Software is what is used to design the jewelry as well as translate your design into instructions for your printer.

Your materials matter as well- common ones are resin and plastic. The build volume is how much room you have in your 3D printer for jewelry casting. The resolution is how detailed your jewelry will be. Lastly, there are many extra features your printer can have, such as increased speed or having an app to help control the printer.

More features: monochrome LCD, fast printing speed, high-quality Z-axis

This 3d printer uses parallel light sources and has uniform exposure. It has a Z-axis guide rail for better stability and accuracy of .01mm. It eliminates layer patterns. It prints 2.5 times faster than normal 3d printers. It only takes 1.5 seconds to cure the resin for each layer exposure. It comes with lifetime technical support.

This is the perfect printer for someone who is looking for something that is quick without sacrificing quality. Even though it moves faster than your average printer, layer patterns are still invisible, and the accuracy is incredible. The resin cures, and your work will solidify very quickly.

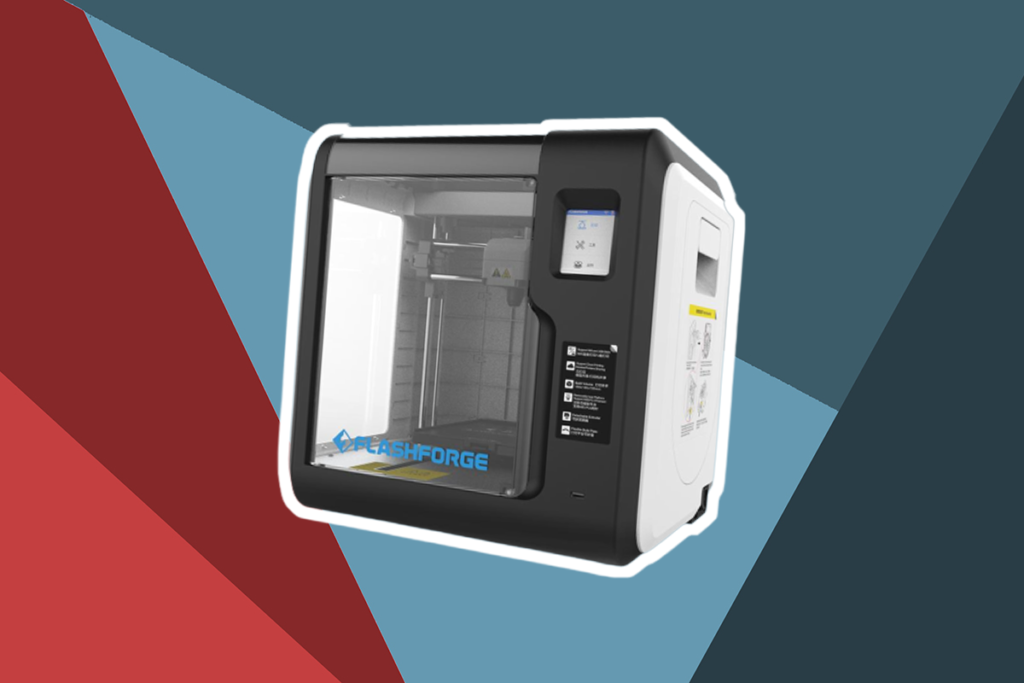

More features: large build volume, App remote control

This 3d printer for jewelry has an 8.9” monochrome LCD at 4K resolution. This allows for big prints and great accuracy and detail. There is a large build area for big creations. It is also remote-controlled by an app. It has a safety feature where the printer shuts off when the top cover is taken off.

This is the new and improved version of the Photon. The LCD is 4K instead of 2K. It prints 3x faster. The build area is much bigger, with a length that is roughly 80mm bigger, a width that is roughly 60mm bigger, and a height that is roughly 100mm bigger. If you are looking for bigger, faster, more accurate builds, this is the version for you.

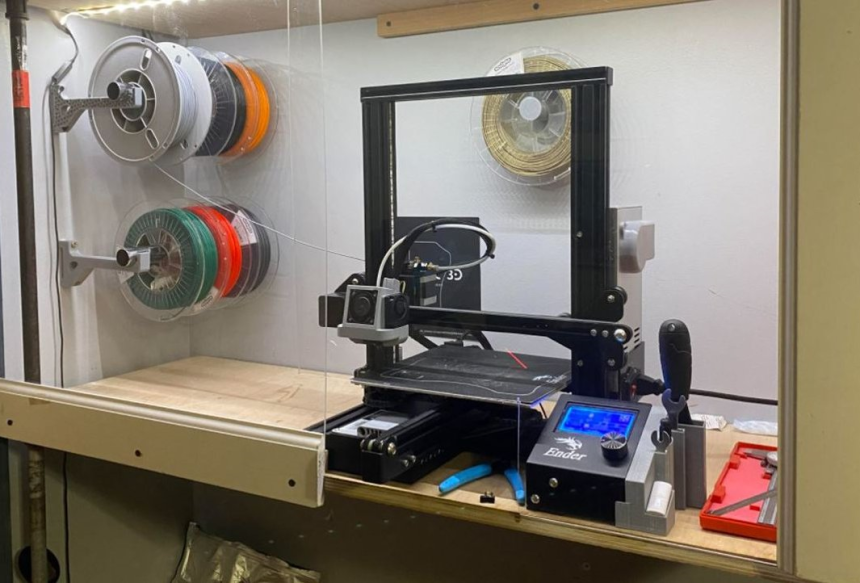

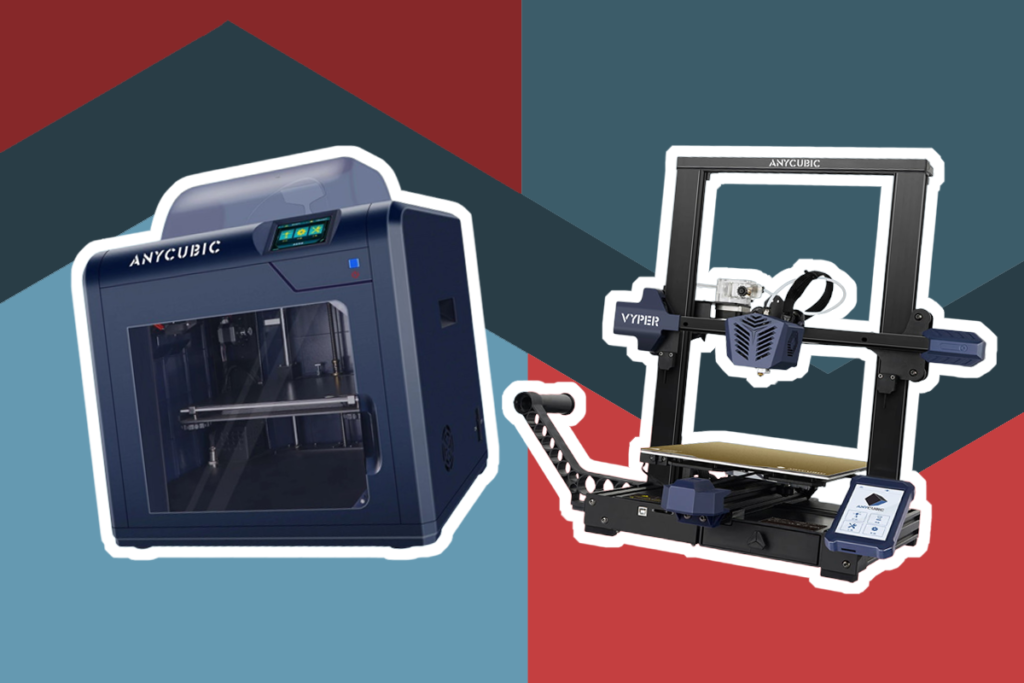

More features: double Z-axis, newly developed extruder, removable plate, touchscreen

This printer comes with two extruders. One has a max temperature of 250C and the other 300C. It also has two different choices for how you place filament. It has a double Z-axis driver for more precise and stable printing when printing larger models with your 3D printer for jewelry.

This product is an improvement on the brand’s previous printers. Extruder B is their newest development. Its slicer software is version 5.6.4 and is a redesigned interface that is smarter and easier to operate. It has a new slicing algorithm with a 30% better print quality and is 20% faster.

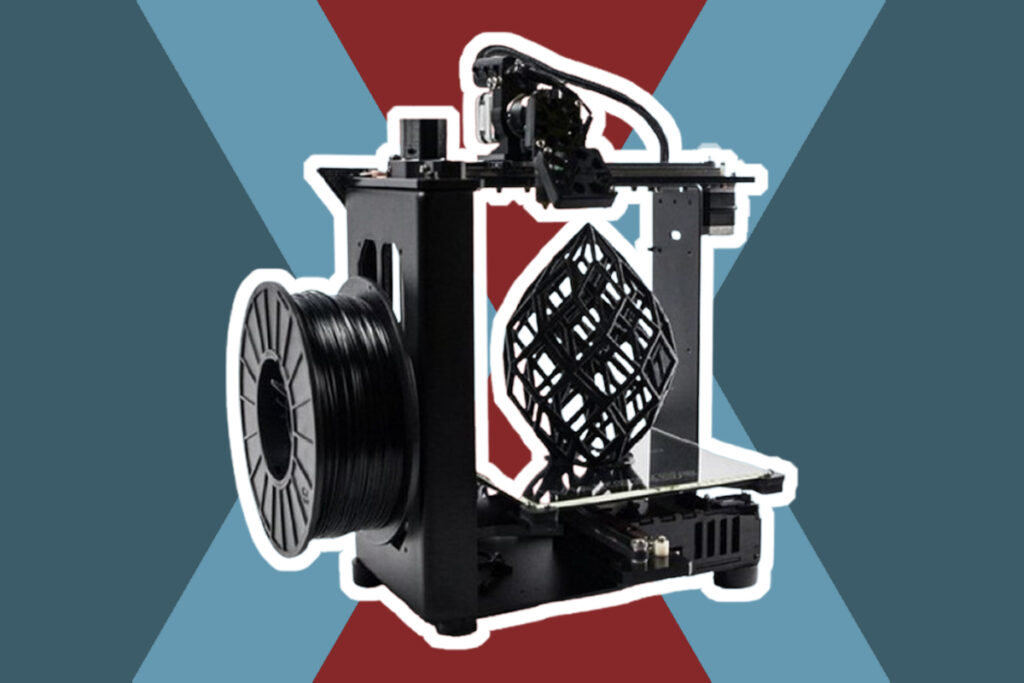

More features: UV light tech, big printing area, high resolution, multi-resin compatibility

The Sonic Mighty 4K has a huge printing area, so you can print many quantities in one batch. It has a 22cm Z-axis and dual-liner rails. It prints 4 times faster than traditional 3D printers for jewelry casting. Each layer is printed in just two seconds. It has 2,000 working hours as well as a 3-month warranty.

This product is perfect for people who want to print a lot in a single batch. It has a very large area for printing, coming in at 9.3 inches. This lets you print out nearly as much as you want in a single sitting. It is extremely efficient, and its size doesn’t mean it’s slow- it can print much faster than the average printer, giving you more jewelry in less time.

More features: fast printing, multi-language interface, sturdy, ultra-accuracy, UV integrated light

This 3D printer for jewelry casting has a 6.08-inch monochrome LCD with a resolution of 2K HD. Each layer takes two seconds to cure. It has an incredibly long lifespan. The light source is new from older models and gives more UV light. It comes in 12 languages, so anyone can operate this machine.

This 3D printer for jewelry is great for someone whose first language isn’t English. With 12 different languages, really anyone can use this machine. It is also good if you don’t need that large of a workspace. It is relatively compact, so you don’t have to pay extra money for an amount of workspace you will never use.

You can make anything with a jewelry 3D printer! You can make rings, bracelets, earrings, necklaces, and more. You can even make things that aren’t jewelry. It is popular for people to print out their favorite characters from board games or RPGs that they play. You can print out parts for a machine using a 3D printer for jewelry casting. Surprisingly, it is even possible to build a house!

Your jewelry can be made up of different materials like resin or plastic. The build volume is how much room you have to make jewelry inside your 3D printer for jewelry. The resolution is how detailed your jewelry can be. Extra features include increased speed, monochrome LCD, safety features, apps, and more. Power is how much power your printer uses.

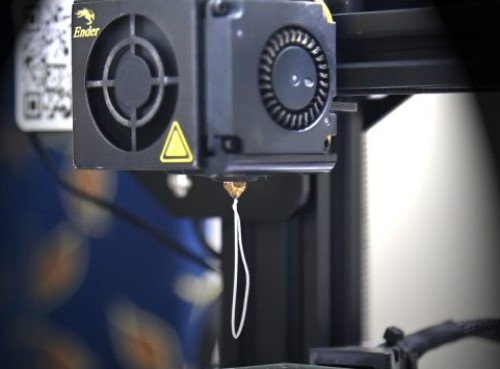

There are two different printing technologies covered in this 3D printer for jewelry review, and those are LCD and LCD-based SLA. LCD-based SLA uses LCD to solidify the resin. The LCD is shone from the bottom of the machine and directed by mirrors to the desired location. This happens for each layer and keeps repeating until the piece is finished. SLA is the oldest printing technology. It is often used with lasers instead of LCD.

LCD 3D printers for jewelry making are incredibly popular because the technology can be used for cheap. They use resin just like SLA printers. They use LCD panels with LED lights in them to cure the resin. They flash the layer all at once to cure the resin without using mirrors. They use a panel instead. The screen only passes light through areas that need to be cured. The ANYCUBIC Photon Mono and the ANYCUBIC Photon Mono X use LCD-based SLA.

3D printing software is unique to each printer, but they all do similar things. They all help the 3D printing and design process. They can be slicers, CAM, CAD, or design automation. They can create complex jewelry models that are then sliced into very thin layers, which become the blueprint to a 3D model that the 3D printer then prints. The main job of 3D printing software is to build the models and then to transfer the models into instructions that the machine will understand.

The most commonly used material in our 3D printers for jewelry-making review is

resin

Trusted Source

Resin - Wikipedia

Plants secrete resins for their protective benefits in response to injury. The resin protects the plant from insects and pathogens. Resins confound a wide range of herbivores, insects, and pathogens, while the volatile phenolic compounds may attract benefactors such as parasitoids or predators of the herbivores that attack the plant.

en.wikipedia.org

. Resin is an umbrella term for liquid photopolymers. It is used in layers in order to build a full object. It is liquid that is then cured by lights in the printer to become solid. The resin is stored in a vat.

Plastic is another material used by the printers we reviewed. Again, it is an umbrella term. ABS is the most common plastic used for printing. ABS is a thermoplastic. It can be found in cars and appliances.

The R QIDI TECHNOLOGY 3D Printer uses Acrylonitrile Butadiene Styrene, Polycarbonate, Thermoplastic Polyurethane, Carbon Fiber, Polylactic Acid, and Nylon. The Phrozen Sonic Mighty uses resin. The ELEGOO Mars 2 Pro 3D Printer uses plastic and resin.

The build volume of a 3D printer for jewelry casting is the dimensions of the space where jewelry can be printed. These are in Cartesian form, which means using the X, Y, and Z axes. This is because most 3D printers for jewelry use a Cartesian-based system where the motion takes place in three axes.

In 3D printers for jewelry casting, there are three dimensions for resolution. There are the two planar 2D dimensions, which are X and Y, and there is the Z dimension which turns it from 2D into 3D. The planar dimension and the Z dimension are controlled by different things, so their resolutions are going to be different. XY resolution is what mostly contributes to print quality. You want a smaller number for the resolution because that will mean higher quality.

The ANYCUBIC Photon Mono has a resolution of 0.01-0.15mm. The ANYCUBIC Photon Mono X has a resolution of 0.01-0.15mm. The R QIDI TECHNOLOGY 3D Printer has a resolution of 100-500 microns. The ELEGOO Mars 2 Pro 3D Printer has a resolution of .05mm.

There are a lot of extra features you can want in a 3D printer, such as being controlled by an app, having safety features, high speed, and more. These extra features are what can make or break your printing experience using your 3D printer for jewelry making.

Depending on where you are in your 3D printing journey, you should pick a printer that is wallet-friendly. One thing to consider while doing this is how much power your printer uses. Printers can use a lot of power. Power is the current multiplied by the voltage. The hotbed and heated beds, as well as the lights, all use power. Most 3D printers for jewelry casting use 50 watts of power each hour.

We reviewed many 3D printers for jewelry making and went over all the features that made them great. But our top choices have to be our Editor’s Choice, our Best Value, and our Premium Pick. These are the printers that went above and beyond when we considered all the features they had. Our Editor’s Choice is the ANYCUBIC Photon Mono. It is a fantastic printer that prints incredibly quickly and has great resolution. Our Best Value is the ELEGOO Mars 2 Pro 3D Printer. This printer comes in 12 different languages and is compact, perfect if you don’t have a large workspace. Lastly, our Premium Pick is the ANYCUBIC Photon Mono X. This printer has an incredibly large build volume and has an app that controls it. These are the best 3D printers for jewelry on the entire market. So follow your dreams and make jewelry using a 3D printer!